Dwyer MTL7787 User Manual

Page 10

6

INM7700-6 Jan 2010

High - profile

DIN rail

OR

Low - profile

DIN rail

2 off M4 x 16

M6 X 16

50mm

62mm

14.6mm

20mm

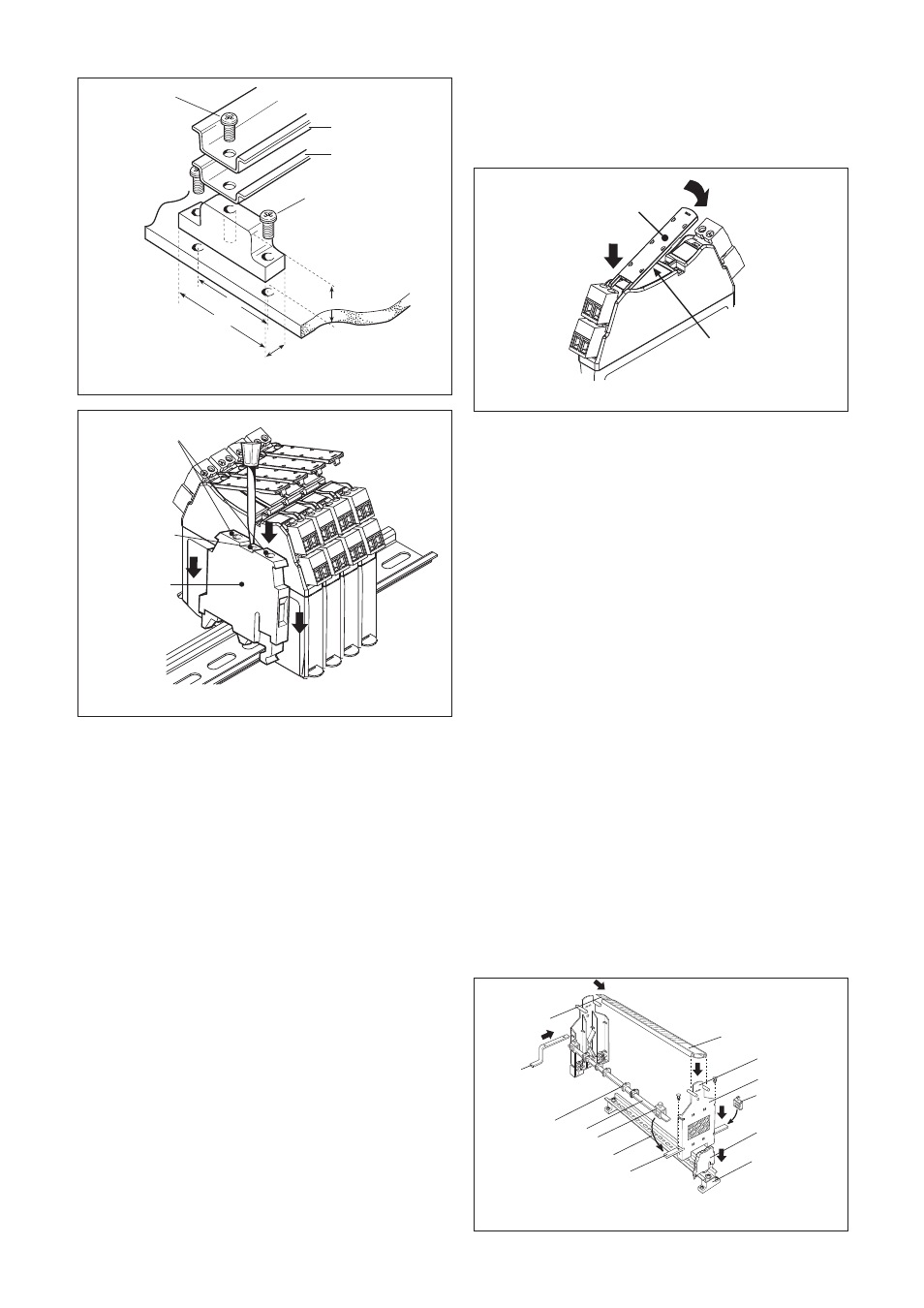

Figure 9: Mounting ISP7000 insulating spacers

ETL7000

earth terminal

Clamping

screw

Earth terminal

screws

Figure 10: Mounting an ETL7000 DIN-rail earth terminal

TH7700

LABEL

Figure 11: Installing a TH7700 barrier tag holder

4.3.4 Earth rail assembly (ERL7/ETM7/ERB57S/O)

A screw terminals on each barrier is available for terminating cable

screens and 0V returns. An alternative is provided by an earth rail

assembly (figure 12). This consists of two IMB57’s, ERB57S or O,

mounting blocks (one for each end of a column of barriers), a length

of ERL7 earth rail (supplied in 1m lengths for cutting to size), and

ETM7 terminals for connecting cable screens or 0V returns to the rail.

Install the earth rail assembly as follows:

a) Hook the loose end-clamps of the IMB57 mounting blocks over

the flanges of the DIN-rail at each end of the row of barriers.

b) Making sure the blocks are flush with the end barriers or tagging

strip supports, clamp them firmly into place by tightening the

screws at the base of the blocks and fit 2 off ERB57O or S into

supports.

c) Slide the number of ETM7 terminals required for connections

onto the length of ERL7 rail needed for the assembly.

d) Important: wire up the earth rail assembly as given in section

5.3.3.

4.3.5

Barrier identifiers (TH7700)

TH7700 tag holders (figure 11) are clipped onto the tops ofindividual

barriers to provide transparent holders for identification labels

a) Slide the required label in between the top and lower parts of

the TH7700

b) Push the tag holder downwards until it clips into place.

c) To unclip a tag holder, lever up the far end above terminals.

4.3.6

Tagging strip assemblies(IMB57)

The tagging strip assembly (figure 12) identifies the location of

individual barriers, ensuring that they are replaced correctly after

removal for maintenance or testing. Once installed, the tagging strip

pivots upwards to provide access to, and allow removal of, individual

barriers.

Each assembly uses two tagging strip supports (IMB57), a tagging

strip (TAG57) and tag labels (TGL7700).

The assembly installation procedure is:

a)IMB57 tagging strip support. Making sure that the vertical

slots are on the hazardous-area side, hook the loose end-clamps

of each IMB57 tagging strip support over the flanges of the DIN-

rail at each end of the group of barriers.

b) Make sure that the tagging strip support is flush with the end

barrier in the row.

IMB57 tagging strip support. Clamp firmly in place by

tightening the two screws located at the foot of each support.

c) Remove any clic rivets from the tagging strip and slide out the

label.

d) Measure the distance between the top inside faces of the two

tagging strip supports.

e) Cut the tagging strip and label to this length with a hacksaw.

f) Annotate the tagging strip label as required and slide it back

into the tagging strip. Divisions on label strips are 12.6mm

wide, the pitch of individual barriers.

g) Clip the tagging strip onto the lugs on top of the tagging strip

supports.

4.3.7

Power bus (BPL7700)

For details on using and installing a power bus, see section 5.2.3.

Note: Early versions of TH7700 are hinged on two small locating

pins. Later versions are hinged by locating the clips at the hinged end

into the rectangular appartures on the barrier body. The later design

can be retrofitted on early modules by removing the hinge pins with

a knife.

TGL7700

ERB57O

TAG57

ERL7

ETM7

14mm earth-rail

clamp

THR2/THR7000

ERB57S

in lower position

ISP7000

ETL7000

10mm earth

clamp

IMB57

Snap off extension

when using IMB57

as a central support

Figure 12: Mounting earthing and tagging accessories