Dwyer UTS User Manual

Page 5

Flexible Cable

Flexible sensor cables are supplied with 16.4 ft/5 m loose-end cable. However, they

can be modified to fit longer length than 16.4 ft/5 m. The modifications in the cable

length can be made according to following tables:

UTS-1XX-XXX-X

UTS-2XX-XXX-X

Chapter 2: Installing Series UT

Precautions

• Ensure that the Series UT components are mounted in an area that meets the

stated temperature, pressure and technical specifications.

• Ensure that high-voltage sources or cables are at least 3.28 ft/1 m away from the

sensor and its cable.

• Use round cables with minimum diameter of 6 to 7 mm to ensure that the unit

remains sealed to enclosure rating listed (IP65/67).

• Ensure that cables are routed correctly and tightened along walls or pipes.

• Ensure that all cables are overall shielded (sensor cable, interface cable, power

cable and current cable).

• Installation and operation of this product should be performed according to the

Installation and Operating Instructions; otherwise, the use of this product is

prohibited.

Installing the Series UT Sensor (UTS)

The following procedures describe sensor installation using 1˝ or 2˝ threading and

a correlating locking nut. The installation procedure is the same whether the sensor

is mounted directly on the tank or mounted on a pipe.

To Install the Sensor Using 1˝ Threading:

1. Open the required tank (or pipe).

2. Feed the free end of the sensor cable from the inside of the tank through the

aperture at the top of the tank until the sensor is pulled taut against the ceiling.

The threaded end of the sensor should protrude from the top of the tank.

3. Spread silicon grease around the threading to seal against leakage (you can also

use a FEP band).

4. Thread the free end of the sensor cable through a 1˝ locking nut (not supplied

with the Series UT unit). Bolt the sensor into place by securing the nut to the

sensor thread protruding from the top of the tank.

5. Wire the sensor cable to the main Series UT unit, as described on page 5.

To Install the Sensor Using 2˝ Threading (UTS-1XX-XXX-X (25 kHz) Standard

Range Sensor):

• Follow the procedure described on the previous page for 1˝ threading, using a 2˝

locking nut with the 2˝ BSP/NPT sensor threading.

Threading Options

Series UT sensors are available in BSP or NPT thread types. The UTS-2XX-XXX-

X (50 kHz) sensor can be installed using 1˝ threading. The UTS-1XX-XXX-X (25

kHz) sensors can be installed using 1 or 2˝ threading. (Refer to Figure 6: Series UT

Sensor Dimensions in Chapter 1: Introduction.)

25 kHz Sensor Cable Length (ft/m)

16.4 to 164 ft/5 to 50 m

49.21 to 328 ft/50 to 100 m

328 to 492 ft/100 to 150 m

492 to 656 ft/150 to 200 m

Page 4

50 kHz Sensor Cable Length (ft/m)

16.4 ft/5 m to 328 ft/100 m

328 ft/100 m to 656 ft/200 m

NOTES:

Any cable length beyond 328 ft/100 m, may affect the measuring range by

reducing the range.

NOTES:

If applicable, you can also install the sensor by screwing it directly into the tank or

pipe threading. Ensure that the tank/pipe threading matches the sensor threads.

NOTES:

Tighten the nut by hand only. When tightening the nut, hold the lower part of the

sensor.

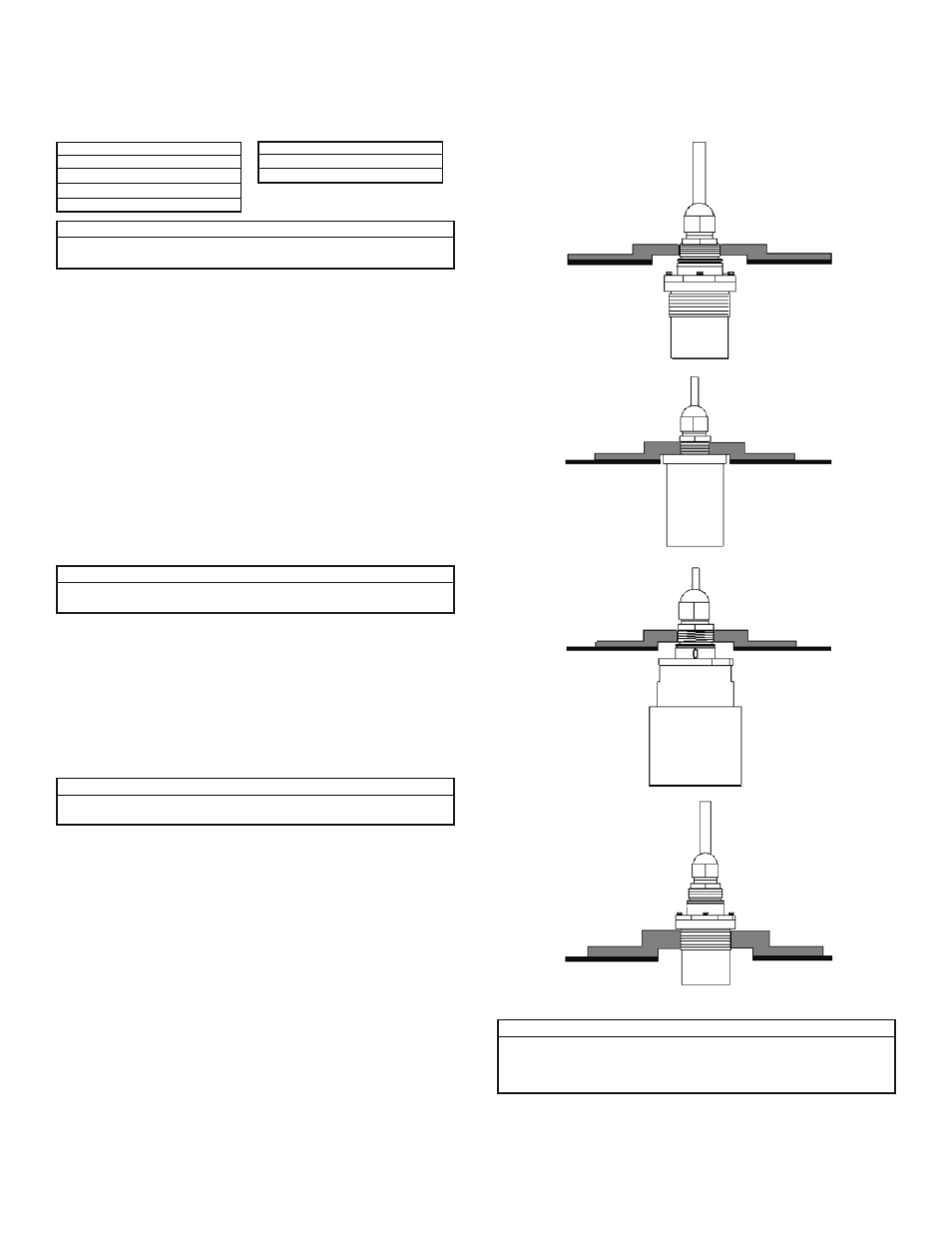

1˝ BSP/1˝ NPT

Threading for

UTS-1XX-XXX-X

(25 kHz) Sensor

(Standard Range)

1˝ BSP/1˝ NPT

Threading for

UTS-1XX-XXX-X

(50 kHz) Sensor

1˝ BSP/1˝ NPT

Threading for

UTS-1XX-2XX-X

(25 kHz) Sensor

(Long Range)

2˝ BSP/2˝ NPT

Threading for

UTS-1XX-1XX-X

(25 kHz) Sensor

(Standard Range)

NOTES:

When installing a thread free flange mounted unit, you will need a 1˝ or 2˝ locking

nut (depending on the thread type used) to secure the sensor to the tank. The nut

can be purchased separately. When installing a threaded flange, ensure that it

matches the Series UT threads.