Dwyer UTS User Manual

Page 13

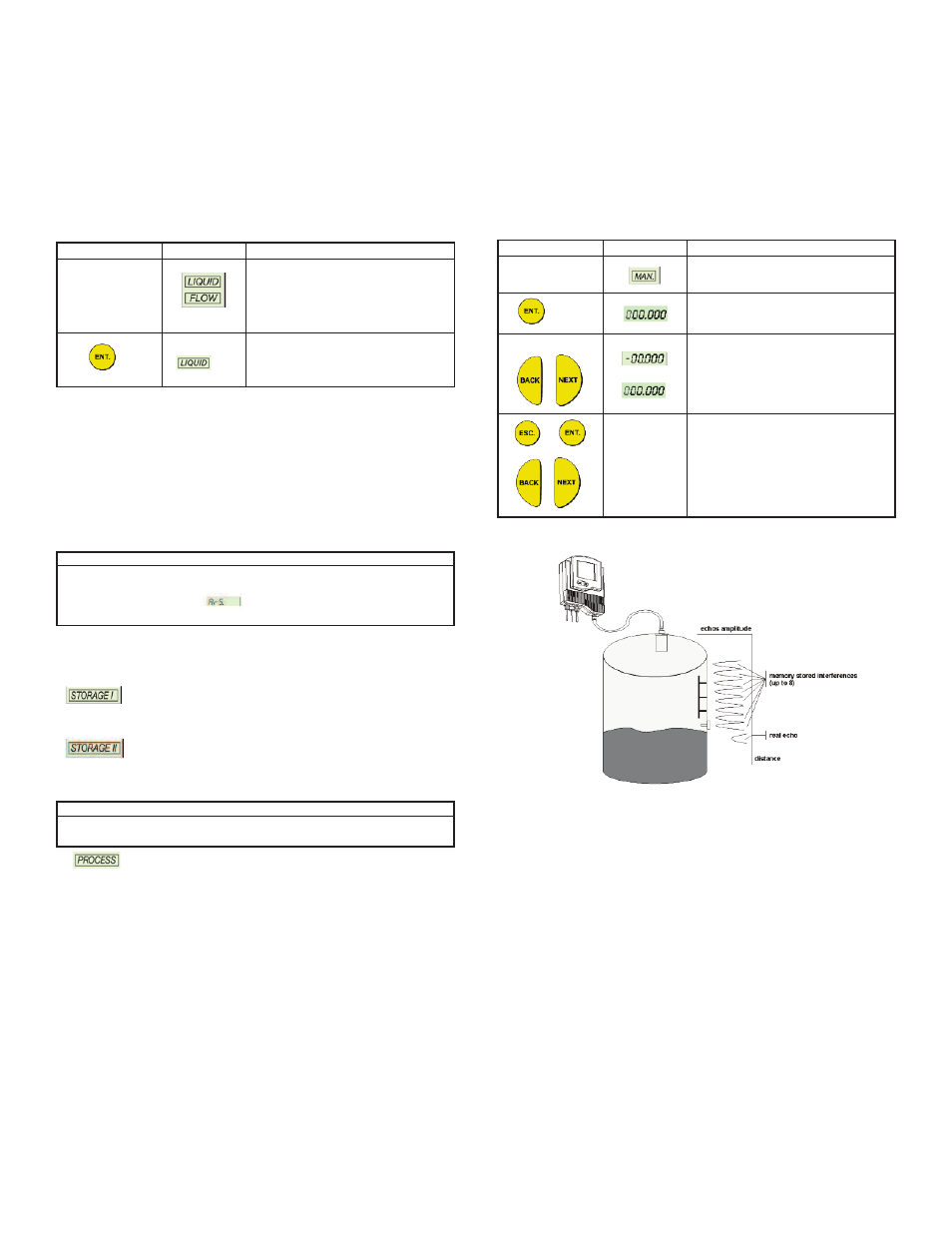

Setting the Application Type

The Series UT main menu displays (by default) LIQUID for models intended for

liquid. Series UT model intended for diameter displays SOLID, LIQUID,

STORAGE I, II and PROCESS (refer to Chapter 6, Diameter Mode Setup).

When Series UT unit is configured as either LIQUID or FLOW (open channel)

model, selecting FLOW option from the indication mode automatically selects the

FLOW option in the application types menu. This should be done before entering

values for other functions, so that all values are automatically adjusted for flow.

To Set the Application Type:

Setting the Operation Modes

The operation modes function enables you to set Series UT to compensate for

environmental conditions that affect the measurement readings.

(For diameter applications, available only for Series UTC model, refer to Chapter 6,

Diameter Mode Setup).

The modes settings are defined by making a selection from the STORAGE I,

STORAGE II and PROCESS options in the main menu; in some cases in

combination with the selection of the LIQUID application. The mode functions and

setup are described in the following sections.

Liquid Modes

Three modes are available for Series UT liquid application models. Each mode is

recommended for use as follows:

• : Recommended in the following conditions:

• Wavy surfaces

• Slow filling/emptying rate

• Applications where the sensor is installed near the tank wall

•

: (Twice as fast as STORAGE I.)

Recommended in the following conditions:

• Reasonable surface conditions

• Applications requiring fast readings

• : This mode is suitable for applications where a fast reading is more

important than precision. A reading will be displayed within a short

time, even if the signal processing procedure was not completed.

Recommended in the following conditions:

• Foamy top surface

• Presence of agitation

• Presence of vapor

• Applications requiring very fast readings

Setting the Sensor Offset

Series UT takes measurements from the tip of the sensor. However, when the

sensor is located at a point that is above or below the true height of the tank, you

can use the MAN function to enter the difference. This may be required, for

example, if the sensor is installed at the top of an external pipe, or at the base of

an internal pipe in the tank.

When the sensor is located above the tank height, the difference must be

subtracted from the actual measurements, so the offset distance is entered as a

negative value and vise versa. The maximum permitted offset value is 2.0 m, and

the minimum permitted value is -2.0 m. Values can be entered in meter units only.

To Set the Sensor Offset Value:

Setting the Scan Distance Values

Up to eight interfering signals (false echoes) can be located by Series UT and

stored in its memory. The false echoes, which may be caused by obstructions such

as a tank agitator or a side wall, can generate false readings and so interfere with

the true scanning of the tank contents. Defining interfering signals is done while the

tank is empty.

Each scan distance reading is stored as an interfering signal until a reading is

achieved that indicates the true echo. If eight interfering signals are already stored

and a ninth reading is received, the first value stored is deleted and the new one

saved.

Page 12

Press/Action

Display

For example.

Explanation

With the required option flashing,

depending on the type of model in use.

Displays the selected option for a few

seconds, and then re-displays the main

menu.

NOTES:

The operation modes are not relevant for flow applications. If one of the

STORAGE I, STORAGE II or PROCESS options is selected when Series UT is in

FLOW application mode, an warning message is displayed and Series

UT reverts to distance mode. You must then reset the unit to flow mode.

NOTES:

STORAGE I and STORAGE II liquid modes are not suitable for measuring

surfaces with foam, since these modes cannot perform signal processing.

Press/Action

Display

Explanation

With the required option flashing.

Default value.

Use to toggle the first digit between a

negative (-) or positive (0) value.

Continue to enter new values for the

remaining five digits.

or

or

or

or

Figure 15: Scan Distance Process