Dwyer instruments, inc, Models and ranges – Dwyer UV User Manual

Page 2

OPERATION AND MAINTENANCE

Once installed, the Series UV In-Line Polysulfone

Flowmeter is self-operating and requires no maintenance

other than an occasional cleaning with mild soap and a

bottle brush. For this purpose, the unit has been designed

so that its body can be removed quickly and easily while

leaving all fittings intact.

When removing float for cleaning, note the floats “up” posi-

tion. The float is a precision part and must be reassembled

without adverse treatment, i.e. dropping, denting, and sur-

face abrasion.

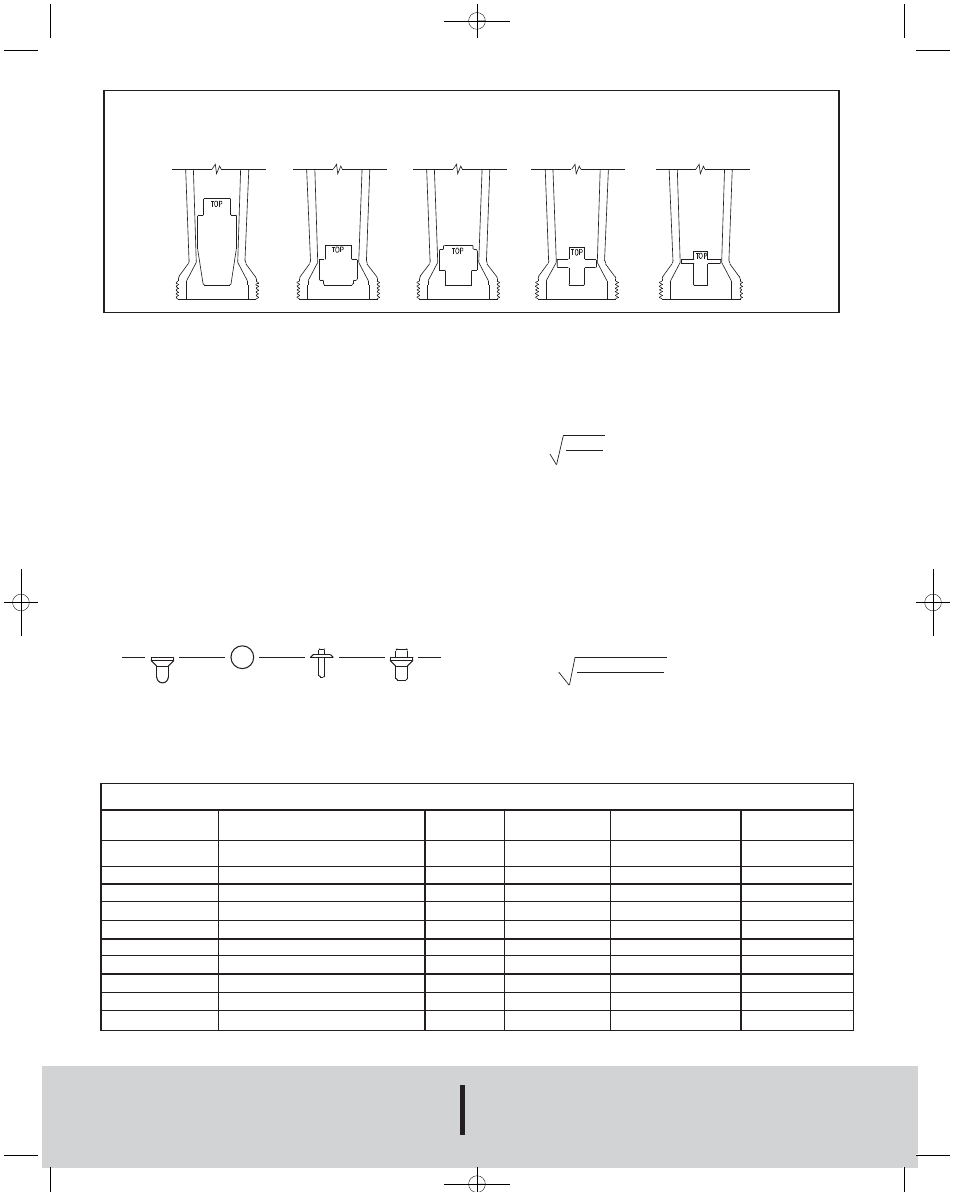

The standard technique for reading a Variable Area Flowmeter is

to locate the highest point of greatest diameter on the float, and

then align that with the theoretical center of the scale graduation.

In the event that the float is not aligned with a grad, an extrapo-

lation of the float location must be made by the operator as to its

location between the two closest grads. The following are some

sample floats shown with reference to the proper location to read

the float.

Variable Area Flowmeters used for gases are typically labeled with

the prefix “S” or “N”, which represents “Standard” for English units

or “Normal” for metric units. Use of this prefix designates that the

flowmeter is calibrated to operate at a specific set of conditions,

and deviation from those standard conditions will require correc-

tion for the calibration to be valid. In practice, the reading taken

from the flowmeter scale must be corrected back to standard

conditions to be used with the scale units. The correct location to

measure the actual pressure and temperature is at the exit of the

flowmeter, except under vacuum applications where they should

be measured at the flowmeter inlet. The equation to correct for

nonstandard operating conditions is as follows:

Q

2

= Q

1

x P

1

x T

2

P

2

x T

1

Where:

Q

1

= Actual or Observed Flowmeter Reading

Q

2

= Standard Flow Corrected for Pressure and

Temperature

P

1

= Actual Pressure (14.7 psia + Gage Pressure)

P

2

= Standard Pressure (14.7 psia, which is 0 psig)

T

1

= Actual Temperature (460 R + Temp °F)

T

2

= Standard Temperature (530 R, which is 70°F)

Example: A flowmeter with a scale of 10-100 SCFH Air. The float

is sitting at the 60 grad on the flowmeter scale. Actual Pressure is

measured at the exit of the meter as 5 psig. Actual Temperature

is measured at the exit of the meter as 85°F.

Q

2

= 60.0 x (14.7 + 5) x 530

14.7 x (460 + 85)

Q

2

= 68.5 SCFH Air

©Copyright 2009 Dwyer Instruments, Inc.

Printed in U.S.A. 7/09

FR# 443147-00 Rev. 6

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

Model Number

UV-0112

UV-1112

UV-2112

UV-3112

UV-4112

UV-5112

UV-A112

UV-B112

UV-C112

UV-D112

Body

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Fitting Material

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Polysulfone

Float

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Virgin PTFE

Models and Ranges

2-20 GPM

3-30 GPM

4-40 GPM

14-100 SCFM

1-10 GPM

.5-5 GPM

2.5-28 SCFM

.25-2.5 GPM

1-13 SCFM

Range

0.25-2.5 GPM (1-9.5 LPM)

0.5-5.0 GPM (2-19 LPM)

1.0-10.0 GPM (4-38 LPM)

2.0-20.00 GPM (8-76 LPM)

3.0-30.00 GPM (12-112 LPM)

4.0-40.00 GPM (20-150 LPM)

1-13 SCFM (30-370 LPM)

2.5-28 SCFM (70-780 LPM)

5-50 SCFM (70-1400 LPM)

14-100 SCFM (400-2800 LPM)

Medium

Water

Water

Water

Water

Water

Water

Air

Air

Air

Air

5-50 SCFM

F-60:Series UV Bulletin 7/24/09 10:01 AM Page 2