Dwyer OP User Manual

Page 2

Installation Tips: (a) If possible, do not install a valve upstream if

it is going to be throttled. Install on the downstream a minimum of

6 diameters from the Series OP. (b) The use of straightening vanes

is not necessary for most applications.

Installation: (a) Insert bolts through bottom half of the flange bolt

circle. (b) Slide OP between flanges (make sure arrow on OP faces

in the direction of flow). (c) Make sure pressure connections are

properly positioned. For horizontal liquid lines, install the OP with

the connections on or under the horizontal center line. For

horizontal air or gas lines, install with the connections on or above

the horizontal center line. They should also be correctly oriented so

as to not be blocked by bolts when remainder of bolts are

inserted. (d) Add rest of bolts and nuts leaving all bolts loose so the

OP is free to move. (e) For non-standard flanges, the OP can be

centered using a steel ruler to measure the total side to side

movement and set OP at half way point all around. (f) Lubricate &

tighten bolts diametrically alternating to recommend flange torque.

(g) Check to insure the OP is installed with the arrow facing in the

same direction as flow. Flange bolts should be 1.25˝ longer than

standard flange bolts.

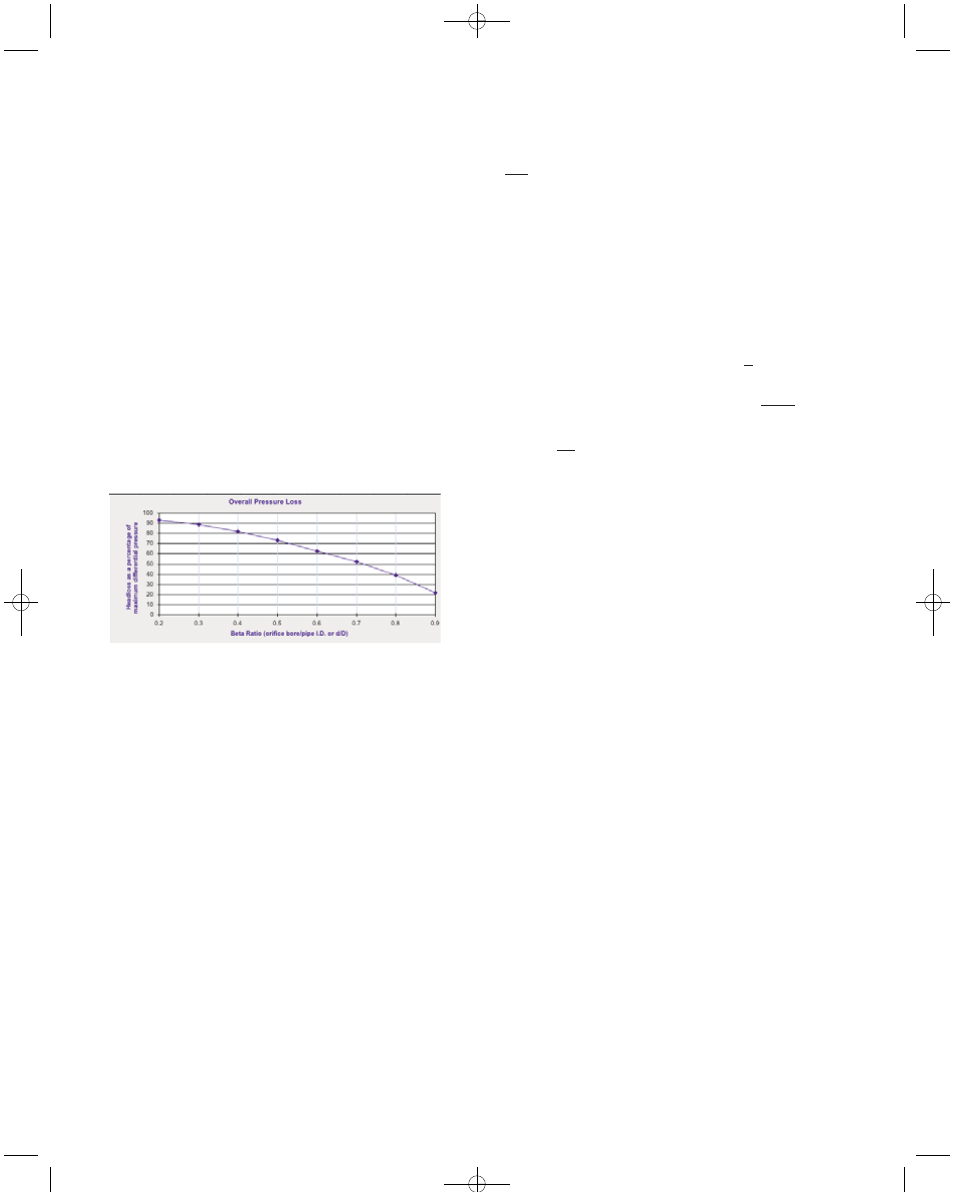

HEAD LOSS

Overall Pressure Loss Across Thin-Plate Orifices

The above curved graph shows pressure loss generated by the

Series OP. For example, a 0.7 Beta Ratio (d/D) would show a loss

of 51%.

As a quick check reference, you can use the formula: Head loss

=1-Beta Ratio

2

eg: 1-0.7

2

or 1-0.49 = 51% of the d.p.

Source: ASME Research Report on Fluid Meters

Magnehelic

®

and Capsuhelic

®

gages from Dwyer read pressure

drop across the orifice plates.

For compatible gases a Dwyer Magnehelic

®

gage may be used to

read the differential pressure. Compatible liquids may be used in

conjunction with the Dwyer Capsuhelic

®

gage with brass case.

FLOW vs. DIFFERENTIAL PRESSURE RELATIONSHIP

(Based on constant inlet temperature and pressure)

[Q

2

/ Q

1

]

2

x h

1

= h

2

Solve for new d.p. based on changes in flow

h

2

/h

1

x Q

1

= Q

2

Solve for new flow based on changes in d.p.

Where:

Q

1

= Existing Flow

Q

2

= New Flow

h

1

= Existing d.p.

h

2

= New d.p.

If the inlet temperature and pressure fluctuate, use the full formula

allowing for input of varying temperature and pressure.

To convert 60°F water flow rates for other fluids:

Pounds per hour (for any fluid) = Q x 63.3 x

γ

L

To convert 60°F water flow rates into flow rates for gases:

Standard cu ft/hour (for any gas) = Q x 63.3 x (

γ

L

)/(

γ

S

)

To convert 60°F water flow rates to GPM for other fluids:

(GPM) / ( SG of fluid)

Explanation of Symbols

Q = 60°F Water Flow Rate in GPM

SG = Specific Gravity

γ

L

= Specific Weight of Line Fluid in lb/ft

3

at line conditions

γ

S

= Specific Weight of Line Fluid in lb/ft

3

at standard conditions

(60°F, 14.7 PSIA)

√

√

√

√

F-OP bulletin:F-OP bulletin 7/24/09 10:06 AM Page 2