Dwyer TVF User Manual

Page 2

MAXIMUM FLOWS (WITHOUT EFFECTING ACCURACY)

FOR UNDERSIZED PIPES CONNECTED DIRECTLY TO MEM FLOWMETER INLETS

PIPE NPS

1/4

3/8

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

6

DATA

(ID)

2

0.132

0.243

0.387

0.679

1.100

1.904

2.592

4.272

6.096

9.413

16.209

36.784

MAX. *

GPM LIQ.

1.72

2.98

4.74

8.31

13.47

23.32

31.74

52.29

74.56

115.2

198.4

450.0

ATMOS

0.864

1.59

2.53

4.44

7.20

12.5

17.0

28.0

39.9

61.6

106

241

50 PSIG

3.80

7.00

11.1

19.5

31.7

58.8

74.6

123

176

271

467

1059

100 PSIG

6.74

12.4

19.8

34.7

56.1

97.2

132

218

311

480

827

1878

MAX. SCFM AIR @ †

200 PSIG

12.6

23.2

37.2

64.9

105

182

248

408

582

804

1549

3514

* Data per Cameron Hydraulic Data. Based on 5 FPS max. liquid velocity having no effect

on Series TVF Flowmeter accuracy if the inlet pipe is smaller than the meter connections.

† SCFM = 0.445 x (psig + 14.7) x (ID)2. Based on 20 FPS max. air velocity having no effect

on Series TVF Flowmeter accuracy if the inlet pipe is smaller than the meter connections.

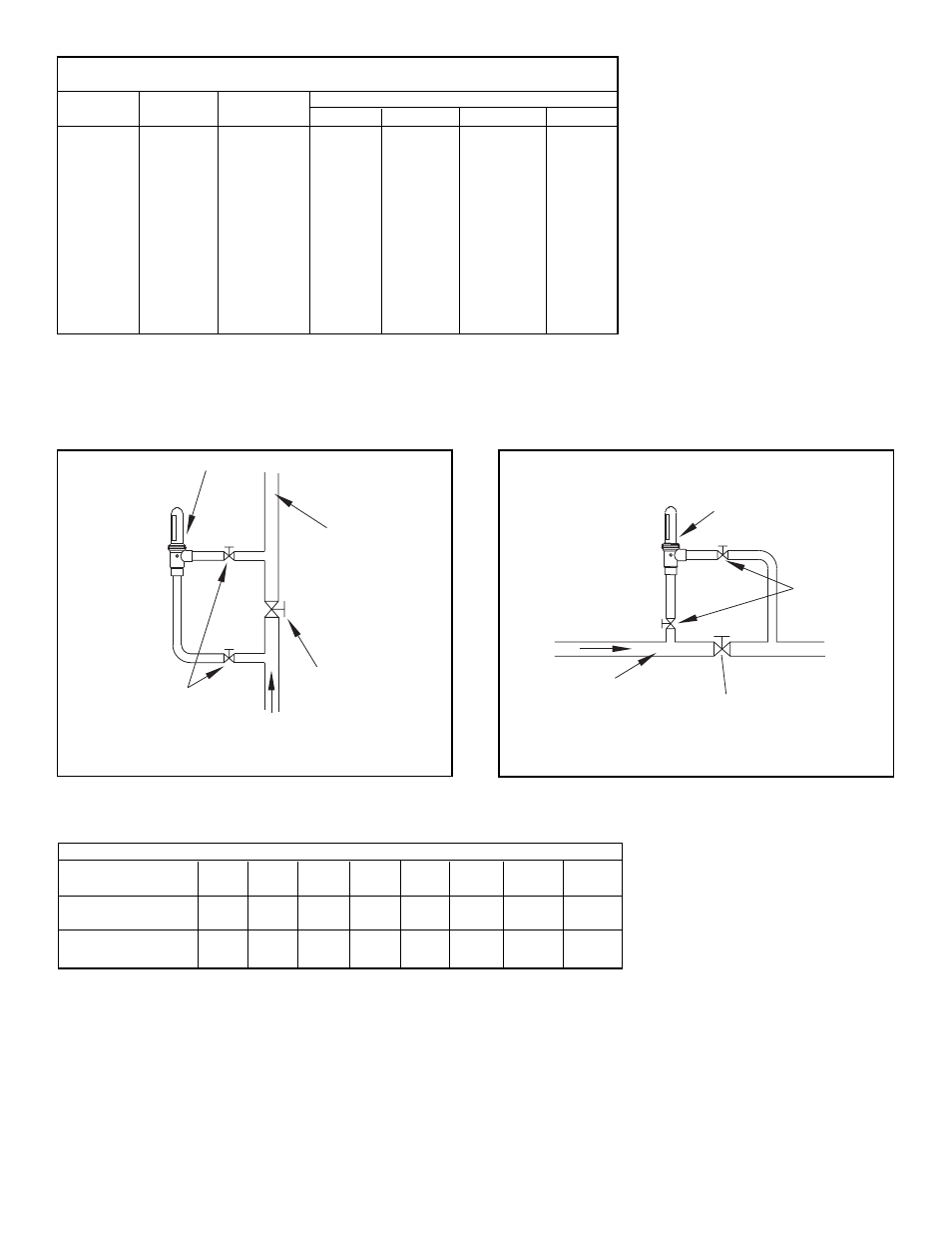

TVF FLOWMETER

MAIN

PROCESS

LINE

BY-PASS

VALVE

FLOW

FIGURE 2: TYPICAL INSTALLATION-

VERTICAL LINE FOR LIQUID, GAS, OR VAPOR

F

SHUT-OFF

VALVES (2)

FIGURE 3: TYPICAL INSTALLATION-

HORIZONTAL LINE FOR LIQUID, GAS, OR VAPOR

SHUT-OFF

VALVES (2)

TVF FLOWMETER

BY-PASS VALVE

FLOW

MAIN PROCESS LINE

OPERATING LIMITS FOR SERIES TVF FLOWMETERS

Maximum Non-Shock Working Pressure, PSIG @ °F (bar @ °C)

BODY SIZE AND

DESCRIPTION

3/4˝ Stainless and

Polysulfone

1-1/2˝ Stainless and

Polysulfone

70ºF

(21ºC)

300

(20.6)

180

(12.4)

80ºF

(26ºC)

300

(20.6)

180

(12.4)

100ºF

(37ºC)

300

(20.6)

180

(12.4)

120ºF

(48ºC)

300

(20.6)

180

(12.4)

140ºF

(60ºC)

300

(20.6)

180

(12.4)

200ºF

(93ºC)

300

(20.6)

180

(12.4)

250ºF

(121ºC)

250

(17.2)

145

(10.0)

300ºF

(148ºC)

115

(7.9)

70

(4.8)

* Operating limits given are based on water or air. For more severe service, corrosives, and

other media and/or environmental factors, an additional correction factor down-rating these

limits may be required. Limits are based on testing and practical experience. Possible

extreme application conditions cannot be foreseen. Thus, data is offered only as a guide. It

in no way constitutes a specific recommendation or warranty expressed or implied. The

operating limits should not be exceeded under any circumstances. If there is any doubt

regarding the safe operating limit for a specific application, please consult the factory prior

to installation and pressurization of the flow device.