Dwyer TDFS User Manual

W.e. anderson div., dwyer instruments, inc, Series tdfs thermal dispersion flow switch

Series TDFS Thermal Dispersion Flow Switch

Specifications - Installation and Operating Instructions

Bulletin F-TDFS

®

W.E. ANDERSON DIV., DWYER

INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46360 U.S.A.

Phone: 219/879-8000

www.dwyer-inst.com

Fax: 219/872-9057

e-mail: [email protected]

The Series TDFS is a thermal flow switch that indicates whether the flow rate is above

or below a user set flow rate. The unit incorporates two LED status indicators providing

visual switch indication. The set flow rate (setpoint) is field adjustable and the unit

has both NO and NC NPN outputs. See Figure 1 for output and LED actions on change

of flow.

SPECIFICATIONS

Service: Compatible water-based fluids.

Wetted Materials: 316 SS, Polysulfone, and FKM.

Setpoint Range: 0.5 to 10 ft/s (0.15 to 3.0 m/s).

Repeatability: 0.07 ft/s +3% of setpoint.

Typical Deadband: 0.1 ft/s +15% of setpoint.

Temperature Limits: Process: 5 to 185°F (-15 to 85°C) (non-freezing); Ambient:

5 to 167°F (-15 to 75°C), Storage: -40 to 185°F (-40 to 85°C).

Pressure Limits: 300 psig (20.67 bar), max. momentary surge: 500 psig (34.47

bar).

Response Time: Approximately 8 s.

Power Requirement: 9 to 24 VDC.

Switching Current: 400 mA, derate 5 mA/°C above 23°C.

Current Consumption: Average: 93 mA, Peak: 300 mA.

Electrical Connection: 1/2˝ NPT female with 4 conductor 22 AWG, 6´ (1.83 m)

long, optional cable gland.

Process Connection: 1/2˝ NPT male.

Enclosure Rating: NEMA 4X (IP65).

Housing Materials: 316 SS, 416 SS, polycarbonate, neoprene, and acrylated

urethane.

Switch Type: 1 NO NPN, 1 NC NPN.

Input Power and Protection: 0.5A fuse (resettable) reverse polarity protected.

Switched Output Protection: 0.5A fuse (resettable) reverse polarity protected.

Agency Approvals: CE, RoHS.

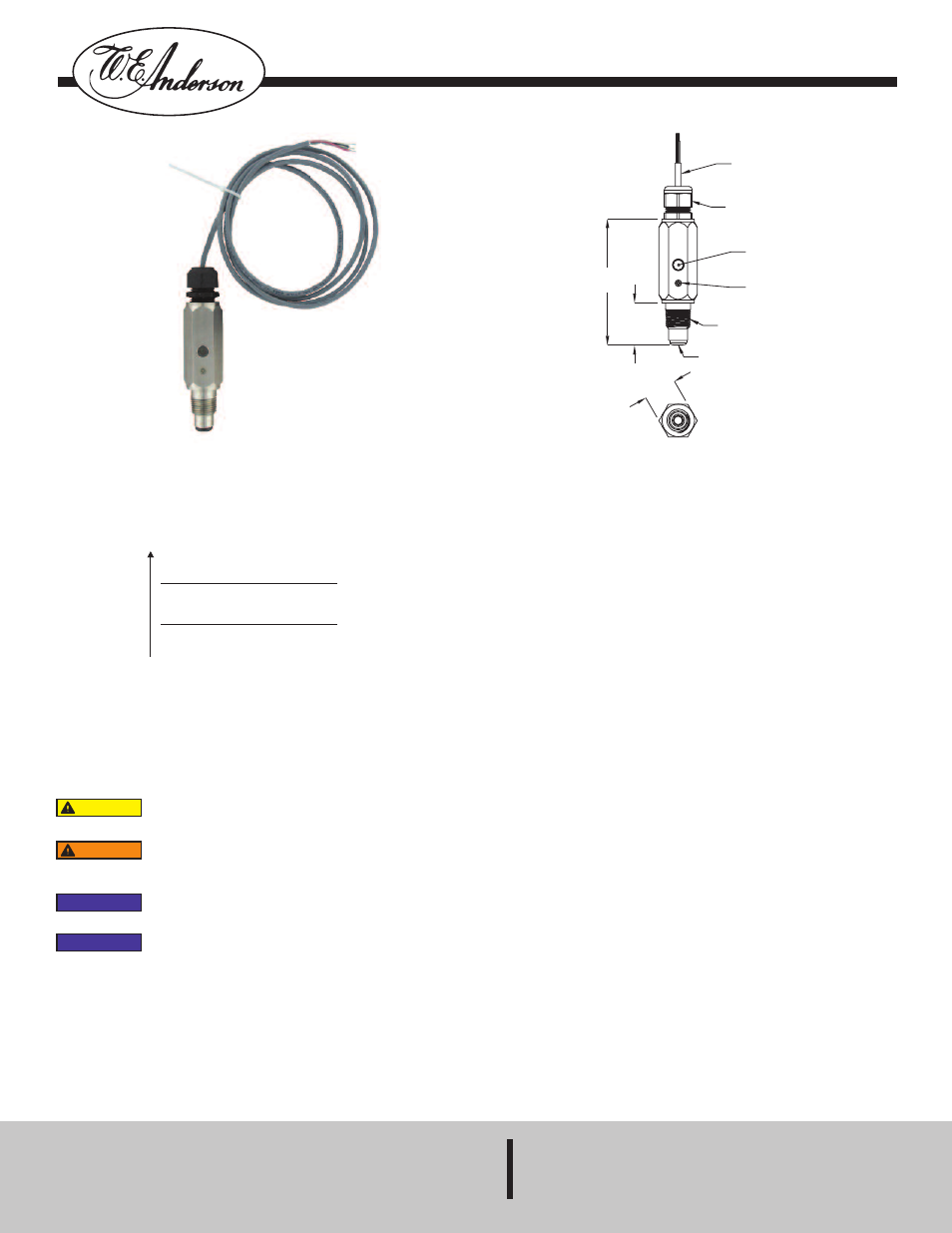

CABLE

CABLE GLAND

STATUS

INDICATOR

SETPOINT

TARGET

PROCESS CONNECTION

1/2˝ NPT

SENSOR

4-9/32

[108.74]

1-7/16

[36.51]

1-1/8

HEX

NC = Open, NO = Closed, LED = Green

Deadband

NC = Closed, NO = Open, LED = Red

Setpoint

Higher

Flow

FIGURE 1: Switch Setpoint & Deadband

OPERATING PRINCIPLE

The TDFS uses an impulse thermal dispersion measurement technique to measure

the flow rate. The probe is heated above the process temperature and then is allowed

to cool. The flow rate is determined from the rate at which the probe cools. The

measurement cycle time is approximately 8 seconds.

INSTALLATION

Use caution if fluid temperature changes or fluid composition

changes are present in the end application. Verify that the

device operates properly if either is present. The setpoint will shift if the specific

heat, density or viscosity of the fluid changes.

NOTICE

Do not use with abrasive fluid mixtures (The polysulfone may be

abraded.)

NOTICE

Ensure that the system is not pressurized before installing or

removing this device or other objects from the system. The

device and/or object may become a projectile.

WARNING

Ensure that the process fluid is compatible with the wetted

materials, and do not exceed the maximum device ratings

CAUTION