Dwyer AFS User Manual

Page 2

Maintenance . . .

Occasional cleaning when excessive contamination is present in the liquid is the

only maintenance normally required. To disassemble unit for cleaning: With

system shut down and no liquid in piping, remove piston plug from unit. Unit need

not be removed from system.

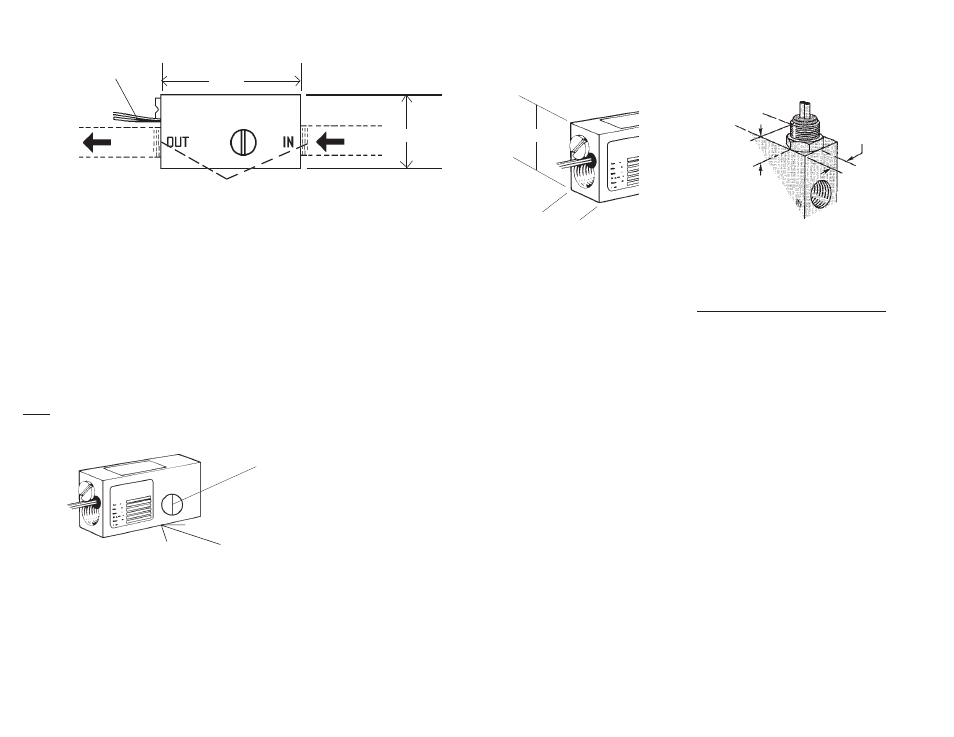

Electrical Connection . . .

1/2"

1-1/16"

1-1/4"

2"

Lead Wires,

Strain Relief

1/2" NPT

Conduit Connector

MAINTENANCE/REPAIR ...

Regular maintenance of the total system is recommended to assure sus-

tained optimum performance. These devices are not field repairable and should

be returned to the factory if recalibration or other service is required. After first

obtaining a Returned Goods Authorization (RGA) number, send the unit freight

prepaid to the following. Please include a clear description of the problem

plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

Flow Setting Adjustment...

Standard units are normally supplied with adjustment set at minimum flow -

adjusting screw slot (and vane within unit) in vertical position, as shown below.

Adjust unit on test stand or installed in system. With liquid (or gas) flow at desired

rate, adjust unit until switch first actuates (opens or closes, as desired).

Note: Vane is locked at Factory with set screw and must be unlocked prior

to any adjustment; then relocked after adjustment has been made.

Adjustment Screw with Slot in

Minimum Flow Position

Locking Set Screw

Dimensional Data . . .

Piping System

Unless otherwise specified, units are factory-calibrated in water for

in-line installation; in horizontal position, as shown above.

4-1/8"

Lead Wires

FLOW

FLOW

Piping System

2"

1/2" NPT

(Both Ports)