Air only) or capsuhelic – Dwyer DS-300 User Manual

Page 2

LP

HP

1-7/16 (36.53)

SENSOR

FLOW

PIPE

1/16 (1.59)

CLEARANCE

HP

LP

LP DRAIN

HP DRAIN

0

.20

.40

.60

.80

1.0

INCHES OF WATER

CAPSUHELIC

®

MAX. OPERATING PRESS. 500 PSIG

ZERO SET

D W Y E R I N S T R U M E N T S , I N C . M I C H I G A N C I T Y, I N D I A N A 4 6 3 6 0 U . S . A .

UPPER PIPE

QUADRANT

LOWER PIPE

QUADRANT

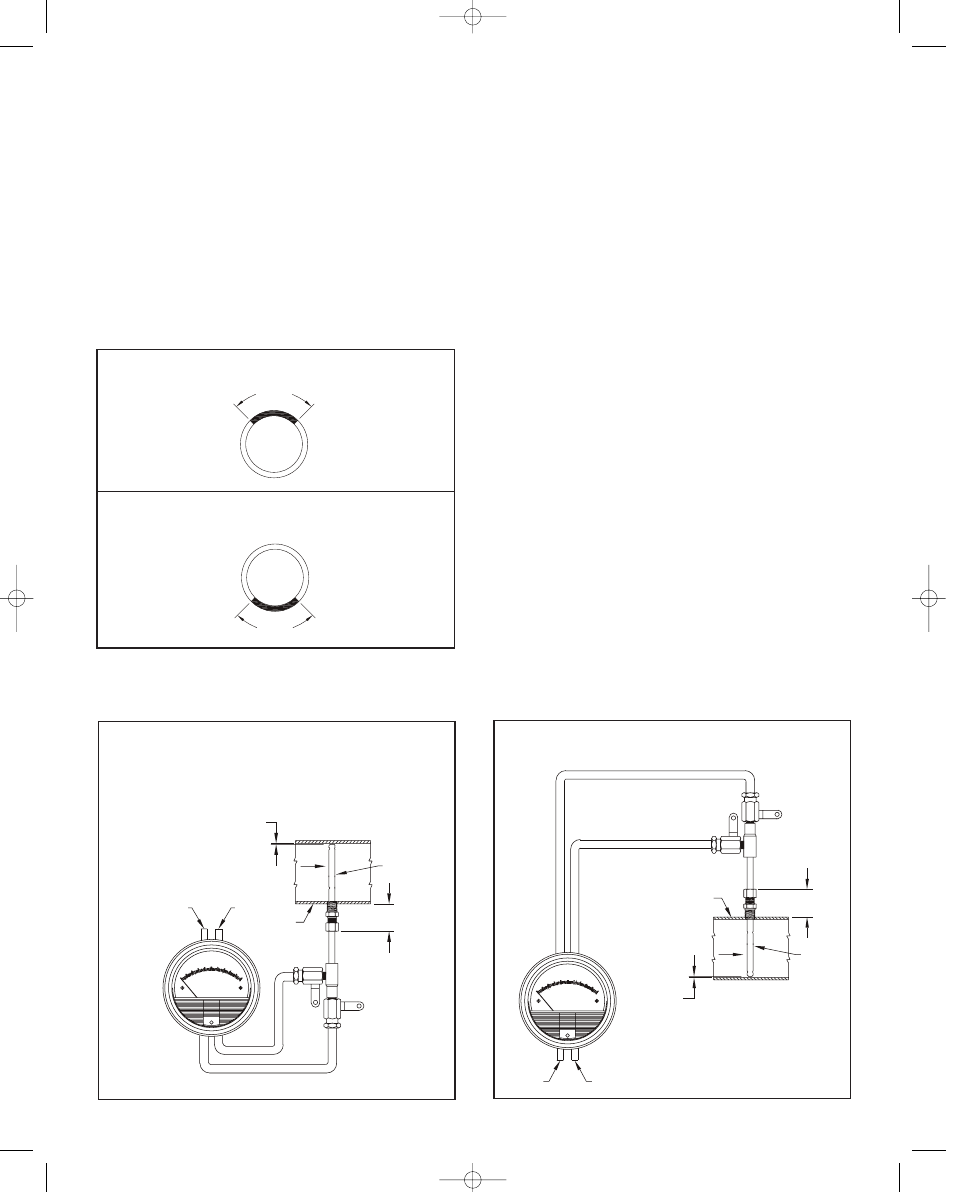

For Air or Gas Flow

Install in upper

quadrant of pipe

Condensate drains

back to pipe

For Liquid or Steam Flow

Install in lower

quadrant of pipe

Air bleeds

back to pipe

LP BLEED

HP BLEED

PIPE

1/16 (1.59)

CLEARANCE

FLOW

SENSOR

1-7/16 (36.53)

LP

HP

HP

LP

INCHES OF WATER

CAPSUHELIC

®

ZERO SET

MAX. OPERATING PRESS. 500 PSIG

.60

.80

1.0

.40

.20

0

DWYER INSTRUMENTS, INC MICHIGAN CITY, INDIANA 46360 U.S.A.

Water Flow

Air or Gas Flow

INSTALLATION

1. When using an A-160 thred-o-let, weld it to the pipe wall.

If replacing a DS-200 unit, an A-161 bushing (1/4˝ x 3/8˝) will

be needed.

2. Drill through center of the thred-o-let into the pipe with a

drill that is slightly larger than the flow sensor diameter.

3. Install the packing gland using proper pipe sealant. If the

packing gland is disassembled, note that the tapered end of

the ferrule goes into the fitting body.

4. Insert sensor until it bottoms against opposite wall of the

pipe, then withdraw 1/16˝ to allow for thermal expansion.

5. Tighten packing gland nut finger tight. Then tighten

nut with a wrench an additional 1-1/4 turns. Be sure to hold

the sensor body with a second wrench to prevent the

sensor from turning.

INSTRUMENT CONNECTION

Connect the slide pressure tap to the high pressure port of

the Magnehelic

®

(air only) or Capsuhelic

®

gage or

transmitting instrument and the top connection to the low

pressure port.

See the connection schematics below.

Bleed air from instrument piping on liquid flows. Drain any

condensate from the instrument piping on air and gas flows.

Open valves to instrument to place flow meter into service.

For permanent installations, a 3-valve manifold is

recommended to allow the gage to be zero checked

without interrupting the flow. The Dwyer A-471 Portable

Test Kit includes such a device.

POSITION

Be certain there is sufficient clearance between the

mounting position and other pipes, walls, structures, etc, so

that the sensor can be inserted through the mounting unit

once the mounting unit has been installed onto the pipe.

Flow sensors should be positioned to keep air out of the

instrument connecting lines on liquid flows and condensate

out of the lines on gas flows. The easiest way to assure this

is to install the sensor into the pipe so that air will bleed into,

or condensate will drain back to, the pipe.

REVISEDBulletin F-50 7/8/04 8:04 AM Page 2