Electrical data, Switch set point calibration with led signal, Specifications panel mounting – Dwyer SF2 User Manual

Page 2

Electrical Data

Input power and output are connected via a

multi-conductor, PVC-jacketed 24" cable.

Color codes are shown below:

+VAC/VDC

Ground

N.O. Contact

N.C. Contact

Common

Red

Black

White

Brown

Green

WARNING

When determining chemical compatibility of

materials of construction, the flow media and

application-associated environmental condi-

tions should be carefully considered.

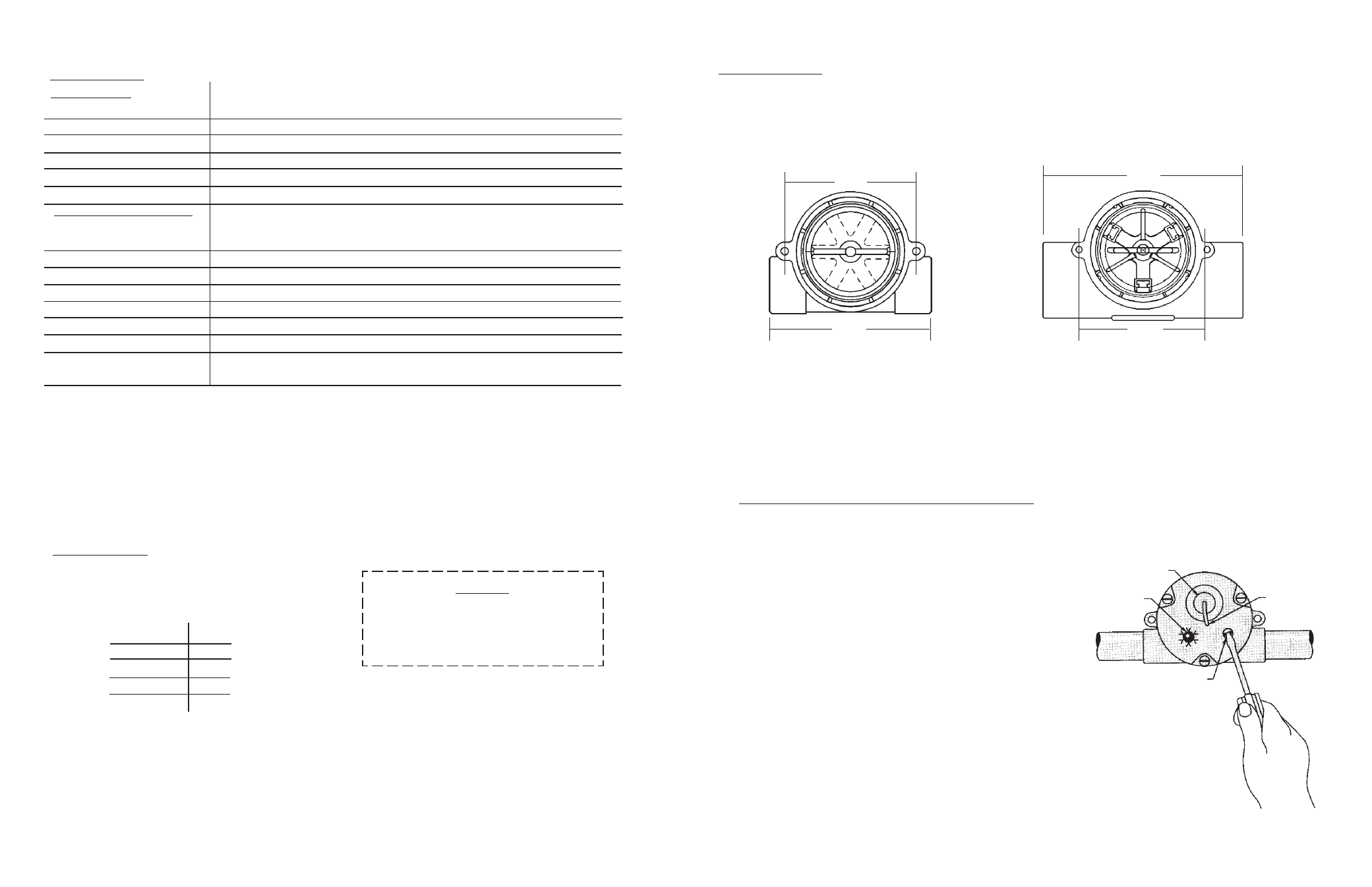

Switch Set Point Calibration with LED Signal

With the unit installed in the line and power supplied, complete the following steps to calibrate

switch actuation point with proper flow rate. A small flat-blade screwdriver is all that is required.

1/2" Strain Relief Hole

LED Indicator Is Illuminated

When Relay Switch Is

Closed. Aids Field

Calibration.

Cable

Output

Set Point

Adjustment

1. Adjust liquid flow in the line to the rate

at which actuation is desired.

Insert screwdriver into opening on

backside of housing and fit blade into

the potentiometer adjustment screw

inside.

If LED is not illuminated, slowly turn

screwdriver counter-clockwise and

stop as soon as LED illuminates.

If LED is illuminated, turn screwdriver

clockwise until LED light goes out.

Then, slowly turn screwdriver

counter-clockwise and stop as soon

as LED illuminates.

2.

3.

4.

Brass

Ceramic

PPS Composite/Teflon/PPS Composite

Polysulfone

Buna N/Viton

200 PSIG @ 70°F 80 PSIG @ 212°F

212°F (100°C)

150°F (65.5°C)

200 SSU

12 VDC, 24 VDC or 110 VAC

1 Amp, 24 VDC Resistive 0.5 Amp, 110 VAC

2% Maximum Deviation

±5%

15% Maximum

22 AWG PVC-Jacketed, 24" Cable. Color codes: Red = +VAC/VDC;

Black = Ground; White = N.O. Contact; Brown = N.C. Contact; Green = Common.

Wetted Materials

Body

Rotor Pin

Rotor

Lens

O-Ring

Operating Pressure, Max.

Operating Temperature, Max.

Brass Body

Electronics

Viscosity, Max.

Input Power

Relay Contact Ratings (SPDT)

Repeatability

Set Point Accuracy (Factory Set)

Set Point Differential

Electrical Termination

Specifications

Panel Mounting

Any SF-2 sensor may be panel mounted using holes integrated into the bodies:

Two (2) mounting holes are provided on the body centerline, as shown below.

#8-32UNC-2B screws are required for mounting.

1/4" &1/2"

2.50"

3.06"

3/4" & 1"

3.94"

2.5"