Connections, Specifications – Dwyer LOFM User Manual

Page 2

The LOFM Electromagnetic Flow Sensor is designed for low-flow

chemical injection or difficult-to-meter applications with pulsat-

ing metering pumps in 3/4” to 1/4” pipe/tube. The housing is

made of sturdy splashproof HDPE plastic.

With no moving parts, the LOFM can handle fluids contain-

ing particulate matter without clogging or jamming, keeping

maintenance at a minimum. With no metallic parts (100%

PVDF body and PVDF carbon fiber-filled electrodes), the me-

ter is corrosion-resistant and compatible with a wide range of

chemicals. Accuracy is maintained with conductive fluids (>20

microSiemens) of varying viscosities and densities.

The LOFM meter is compact enough to fit most pump/injection

systems. With zero straight pipe required after an elbow, it can

be easily mounted in tight spaces. The mounting bracket adds

stability.

The LOFM meter has optocoupled current sinking or current

sourcing pulse output that can be connected to the Dwyer’s

RTI rate/total display or a 4 to 20 mA loop for powering analog

devices. Outputs and power are provided through a cable with

8-pin female circular connector.

gEnEraL inFOrMatiOn, FEatUrES and SPEciFicatiOnS

FEatUrES

inStaLLatiOn and cOnnEctiOnS

inStaLLatiOn

Positioning.

The LOFM can be mounted vertically or horizon-

tally. It is important to choose a position that will ensure full

pipe. (Under certain conditions of empty or partially-full pipe

the meter may give a pulse out when there is no flow.) With a

zero straight pipe requirement after an elbow, the LOFM meter

can be installed in tight spaces.

Mounting.

The LOFM may be supported by its piping connec-

tions IF the piping is rigid. The meter and pipe must be per-

fectly aligned with no flexion at the fittings to prevent damage

to the meter and leakage. It is highly recommended to use the

mounting bracket provided. The mounting bracket uses two #8

screws on a 1.5” center.

Piping.

Metal pipe, metal tube, or plastic tubing can be used

with the meter. The standard FlareTek® fittings can be used

with or without NPT adapters on 3/4” or 3/8” pipe. If used, NPT

adapters should be hand-tightened onto the fittings to avoid

damage to internal O-ring seals. Thoroughly clean the pipe

threads and nose and apply Teflon tape to adapter threads.

Hold fittings/adapters with a wrench while tightening the pipe

to prevent damage to the meter. If using FlareTek® fittings, fol-

low the installation instructions provided with your flare tool.

Power Supply.

A 12 VDC linear, regulated power supply with an

output current of at least 0.25 A is recommended. If a switch-

ing power supply must be used, consult Seametrics for ap-

proved manufacturer’s model numbers.

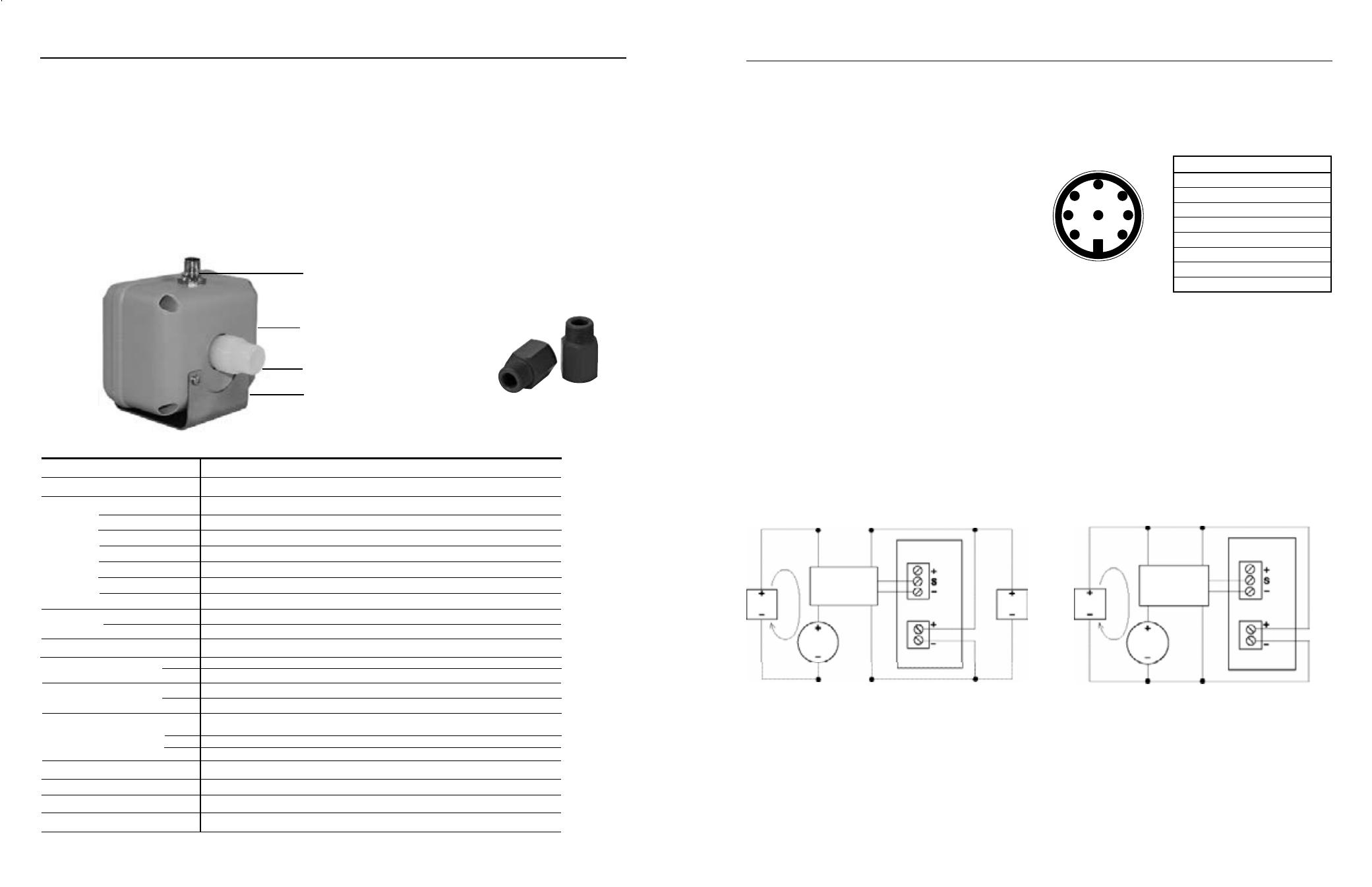

cOnnEctiOnS

Power and signal connections are provided through the 8-pin

male bulkhead connector on the meter housing (20’ (6m)

cable provided). See the Pin Assignment and Connections

diagrams below.

In addition, it is necessary for proper operation to ground the

unit to a good quality earth ground. Assure negative power

supply is grounded to earth and to the entire electrical/me-

chanical system. If metal piping is used, jumper inlet and

outlet pipes together and connect to ground for best results

in metering accuracy.

2

1

3

7

4

6

5

8

Sensor Input

rti

Power

1

LOFM

4-20 ma Device and rti with Single Power Supply

Dual Power Supply with Loop isolation

Pin# Function color

1

Pulse (-)

White

2

Ground

Brown

3

Pulse (+)

Green

4

4-20 (+)

Yellow

5

Not Used

Grey

6

Not Used

Pink

7

4-20 (-)

Blue

8

Power (+)

Red

Sturdy HDPE housing

8-pin circular bulkhead connector, 20’ (6 m) cable provided

FlareTek® fittings

are standard

Threaded NPT adapters

can be purchased separately

(available in PVC or PVDF)

Internals made of chemical and corrosion-resistant PVDF

Mounting bracket

3/4”, 1/2”, 3/8”, 1/4”**

FlareTek® fittings standard in 3/4” or 3/8” flowbody; NPT threaded adapters also available

PVDF

PVDF carbon fiber-filled

PVDF carbon fiber-filled

HDPE with glass fiber

PVDF

PVC or PVDF

EPDM or Fluoroelestomer

0˚ to 130˚ F (-18˚ to 54˚ C)

32˚ to 200˚ F (0˚ to 93˚ C)

150 psi

20 GPM Max. (0.2 GPM cut off)

3 GPM Max. (0.03 GPM cut off)

+/- 1%, +/- 0.005 GPM of reading across rated range

+/- 1%, +/- 0.002 GPM of reading across rated range

Optocoupled current sinking or current sourcing pulse output: 30 Vdc, 5 mA max;

4 to 20 mA current loop: 7 Vdc plus load voltage drop min; 50 Vdc max

PE102-075: 500 pulses/liter (1892 pulses/gallon),

PE102-038: 1,000 pulses/liter (3785 pulses/gallon).

10-15 Vdc, 150 mA (linear power supply recommended)

>20 microSiemens

Hardware/software, conductivity-based

NEMA 4X (IP 66)

Pipe Size

Fittings

Materials Body

Electrodes

ground

Housing

Fittings (Flaretek®)

adapters (nPt)

O-rings (for nPt)

temperature ambient

Fluid

Pressure

Flow range

-1

-2

accuracy

-1

-2

Output Signal

-1

-2

Power

conductivity

Empty Pipe Detection

Environmental

SPEciFicatiOnS*

*Specifications subject to change

**Requires adaptors

FlareTek® is a registered trademark of Entegris, Inc.

12-15

Vdc

4-20

device

4-20 mA

loop

2

3

4

8

7

rti

LOFM

12-24

Vdc

4-20

device

4-20 mA

loop

12-15

Vdc

Sensor Input

Power

1

2

3

4

8

7

cable Plug contact

arrangement

FlareTek® is a registered trademark of Entegris, Inc.