Dwyer BAT User Manual

Page 2

GENERAL INFORMATION, SPEcIFIcATIONS and INSTALLATION

The Dwyer Instruments Inc. Series BAT is a blind (non-

indicating) 4 to 20 mA transmitter, designed for use with Series

EFS2, IEFS, PDWS, TBS and FLMG flow sensors. It accepts a

pulse frequency input from the flow sensor, and converts this

input into a continuous analog output signal. Power for the

transmitter is taken from the current loop itself, so only two

wires are required. The digital design makes it possible to span

the unit in the field without tools. The frequency at which 20

mA is desired is entered on a set of rotary switches, and an

internal microcontroller automatically scales all other values

accordingly. An additional benefit of the microcontroller is its

ability to average inputs, for smoothing of the output signal.

The degree of averaging can be selected in the field, from 2 to

16 seconds.

For maximum environmental protection, the electronic

components are encased in a special semi-flexible urethane

potting material. The housing is cast from aluminum and

fuse-coated. The clamshell housing offered in the BAT-M is

connected directly to the flow sensor or, in the wall mount

version, BAT-W, provided with mounting feet.

The BAT will operate on a relatively wide range of current loop

voltages, 24 to 36 Vdc. Lower voltages limit the load that can

be applied to the loop without distortion of the signal. (See

Load/Supply chart if there is a question regarding voltage vs.

load.) A built-in power regulator supplies the appropriate power

to the flow sensor.

Typical applications for this transmitter are telemetry (or

SCADA), distributed control systems, programmable controllers,

SETTINGS, cALIBRATION and FREQuENcY

Mounting.

The BAT-M can be mounted on the flow sensor.

The BAT-W wall mount comes with mounting feet and

requires four screws to attach it to any stable surface.

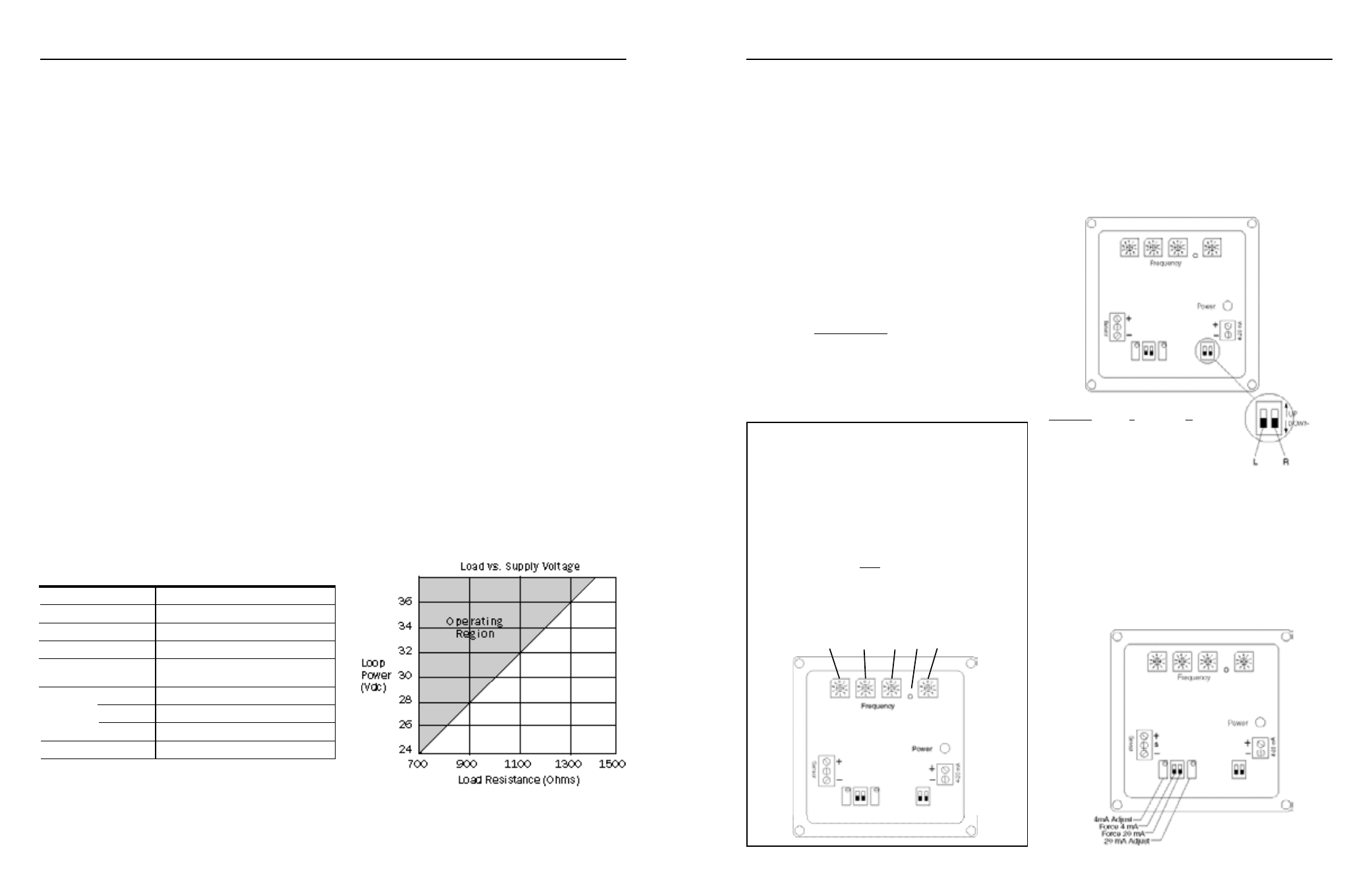

connection.

On either style of housing, the upper portion

must be removed to make connections. Use a standard hex

wrench (5/32” or 4 mm) to loosen the screws, then remove

the upper half. The connections are made to terminal blocks

in the upper half, which contains the potted electronics.

Consult the Connections diagram before connecting to the

current loop. The only connections required on a BAT-M are

the positive and negative loop connections. On a BAT-W,

the sensor must also be connected, since it is remote from

the transmitter. Be careful to follow the color coding of the

flow sensor wires in order to establish the correct polarity.

Incorrect polarity can damage the sensor.

Refer to "Terms and Conditions of Sale" in our catalog or on

our website. Contact customer service to receive a Returns

Goods Authorization number before shipping your product

back for repair. Be sure to include a brief description of the

problem plus any relevant applciation notes.

GENERAL INFORMATION

INSTALLATION

SETTINGS

Setting Frequency.

The BAT converts a train of off/on pulses

from the flow sensor into a continuous mA signal that ranges

from 4 mA at zero flow to 20 mA at the desired maximum flow.

The desired maximum is determined by the user and entered

as a frequency as follows:

1)

2)

3)

4)

Setting Averaging Time.

For most applications this step can

be ignored, as the standard setting will work fine. However,

when a particularly steady output signal is desired, or in a

large pipe, a larger averaging period may be desirable. Note

however that the averaging period requires a tradeoff, since

a longer averaging period implies a slower response time. If

steady signal is more important than fast response, increase

the averaging time as desired. See the diagram below for the

switch positions and their corresponding times.

Decide what flow rate should represent the top of the

scale. This is ordinarily the maximum expected flow, or

a value just above it, in gallons per minute.

Locate the K-factor of the flow sensor (found on the

meter or fitting, or in the instruction manual, depending

on meter model). The K-factor is the number of pulses

the flow sensor produces per gallon of flow.

Calculate frequency, using this formula:

K-Factor x Top Flow (GPM) = Frequency

60

Enter the frequency using the four rotary Frequency

switches. Note the decimal point between the third

and fourth switches.

checking calibration

Normally it should not be necessary to check calibration, since

the digital design of this unit virtually eliminates drift. However,

there are two types of calibration check that can be performed.

Look at the diagram below to locate the 4 and 20 mA force

switches. To force the 4 mA output, put its switch in the up

position. Check the current output at the Power terminals, and

if necessary, trim to 4.00 mA using the appropriate trimpot.

Return the switch to the down position, and repeat the process

with the 20 mA switch and appropriate trimpot.

In an installation with an estimated maximum flow rate

of about 150 GPM, a flow rate of 170 GPM is selected

as the full-scale maximum, the flow at which the current

loop will register 20 mA.

In this example, the K-factor (found on the meter or

fitting, or in the manual) is “K = 54.50”.

Calculate the frequency as

1

5

4

.

4

Rounding to one decimal point, enter 154.4 on the

rotary switches by turning the rotary switch pointers

to the desired digits.

= 154.42

54.50 x 170

60

SETTING FREQuENcY ExAMPLE

1)

2)

3)

4)

Switch Position

Seconds

L

R

2

down down

4

down

up

8

up

down

16

up

up

24 to 36 Vdc

32 to 130˚ F (0 to 55˚ C)

Open-collector solid state sensor

2 to 16 seconds (switch selectable)

2 to 60 seconds; 90% of full-scale

(dependent on input averaging)

10 Hz (@20 mA)

999.9 Hz

4 Rotary DIP switches

Proportional 4 to 20 mA

Power

Temperature

Input

Input Averaging

Response Time

Frequency Minimum

Maximum

Setting

Output

SPEcIFIcATIONS*

*Specifications subject to change

WARRANTY/RETuRN