Dwyer instruments, inc – Dwyer DAFM User Manual

Page 2

©Copyright 2008 Dwyer Instruments, Inc.

Printed in U.S.A. 10/08

FR# R1-443660-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

DAFM

DAFM

DAFM

4˝

12˝

20˝

24˝

AIR FLOW

Short Side Duct Dimension

Figure 1: Top view illustration of probe placement example.

Note: Illustration not to scale.

Please note that all probes should be installed vertically and

running parallel to each other if installed in a rectangular duct.

RECTANGULAR DUCT PROBE INSTALLATION

1. Cut 4˝ X 1˝ holes at locations calculated above in side of duct.

2. Place silicon bead around holes.

3. Slide DAFM into holes and screw four self drilling screws into duct to

attach DAFM.

4. Connect 1/4˝ OD plastic tubing to barb fittings on DAFM.

5. Check all fittings and tubing connections for leaks using a leak

detector.

6. Tee all high and low ports into one high and one low line and connect

to transmitter or gage.

7. The devices should be checked once a year for build-up of dirt of

debris common in an HVAC system.

CIRCULAR DUCT MODELS

Determining Probe Number and Location for Round Ducts

1. Note that in round ducts only two probes are needed. The quantity of

probes needed does not depend on size of the duct.

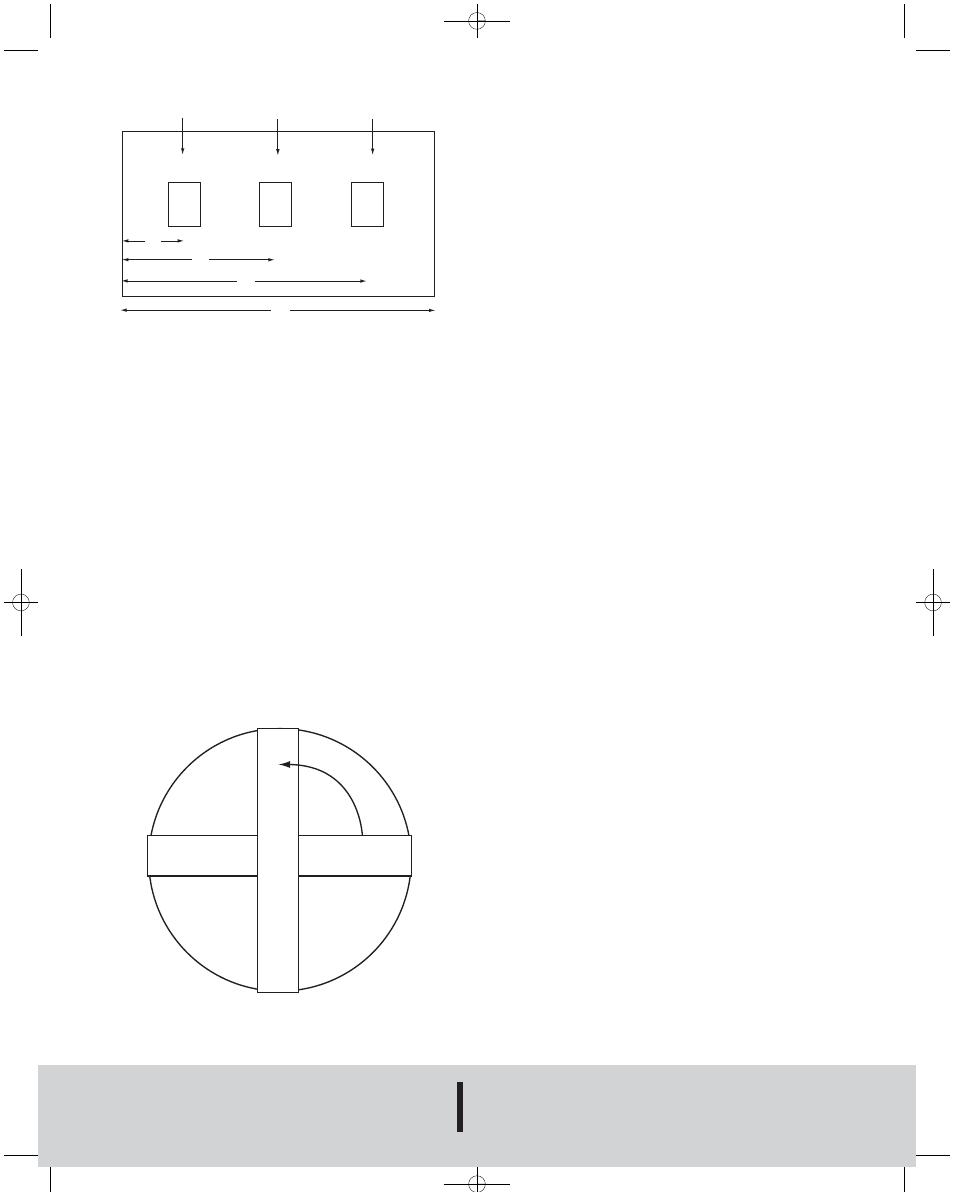

2. Locate probes 90 degrees apart. See Figure 2 for an example.

Figure 2: Cross-sectional view of probe placement in a round duct.

DAFM

D

A

F

M

90°

ROUND DUCT PROBE INSTALLATION

1. Cut 4˝ X 1˝ holes at locations calculated above in side of duct.

2. Place silicon bead around holes.

3. Slide DAFM into holes and screw four self drilling screws into duct to

attach DAFM.

4. Connect 1/4˝ OD plastic tubing to barb fittings on DAFM.

5. Check all fittings and tubing connections for leaks using a leak

detector.

6. Tee all high and low ports into one high and one low line and connect

to transmitter or gage.

7. The devices should be checked once a year for build-up of dirt of

debris common in an HVAC system.

CALIBRATION

Sometimes field calibration may be required if the probe is installed in a bad

location i.e. immediately downstream of an elbow. In order to calibrate, you

must either perform a traverse of the duct or a sum of the air registers and

compare this with the DAFM output. Then, you must make the correction

to the effective area in the computer to make up for the error.

MAINTENANCE

Upon final installation, the device should be checked once a year for a build

up of dirt or debris that can be common in an HVAC system. Also check

the mounting stability once a year. Other than this no routine maintenance

is required. The DAFM model is not field serviceable and should be

returned if repair is needed (field repair should not be attempted and may

void warranty). Be sure to include a brief description of the problem plus

any relevant application notes. Contact customer service to receive a

return goods authorization number.

Long Duct Dimension

AV-2-DAFM:TEMPLATE 10/8/08 8:39 AM Page 2