Dwyer instruments, inc – Dwyer 660 User Manual

Page 2

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09 FR# 02-440751-00 Rev. 3

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

CALIBRATION

1. Determine the velocity at which the HIGH (yellow) and LOW (red)

LEDs should be actuated. The NORMAL (green) LED will be on

when air flow is between the other two limits.

2. Use a suitable instrument to measure air velocity such as a

Model 480 Vaneometer

TM

or Model 471 Thermal Anemometer.

Take readings at 4-10 different locations within the open face area

to determine average velocity. This procedure will be performed

separately for high and low settings.

3. Allow 3-5 minutes warm-up time with no flow before adjusting

the 660 AVM.

4. HIGH setting. Vary blower speed or adjust sash position until

average velocity is at the upper limit required. Be sure air flow is

not obstructed. Turn HSP screw clockwise until LED’s change

from green to yellow.

5. LOW setting. Adjust flow until average velocity is at the lower

limit required. Turn LSP screw counter-clockwise until LED’s

change from green to red. Audible alarm will sound simultaneous-

ly. Press ACK. pad to silence.

6. Repeat adjustment of air velocity to HIGH and LOW flow rates

to confirm proper operation. Make further adjustments to 660

AVM settings if necessary.

7. To confirm proper operation of all alarms, press TEST pad.

MAINTENANCE

No routine maintenance is required for the 660 AVM. Use extreme

caution when cleaning the thermistor bead. The thin glass rod in

which it is housed is very fragile. Use only a soft camel hair brush

to gently remove accumulated dust. After cleaning or replacement

of fume hood filters or other fume hood service, it is recommend-

ed that you check AVM calibration following the procedure above.

The Model 660 Air Velocity Monitor is not field serviceable and

should be returned if repair is needed (field repair should not be

attempted and may void warranty). Be sure to include a brief

description of the problem plus any relevant application notes.

Contact customer service to receive a return goods authorization

number before shipping.

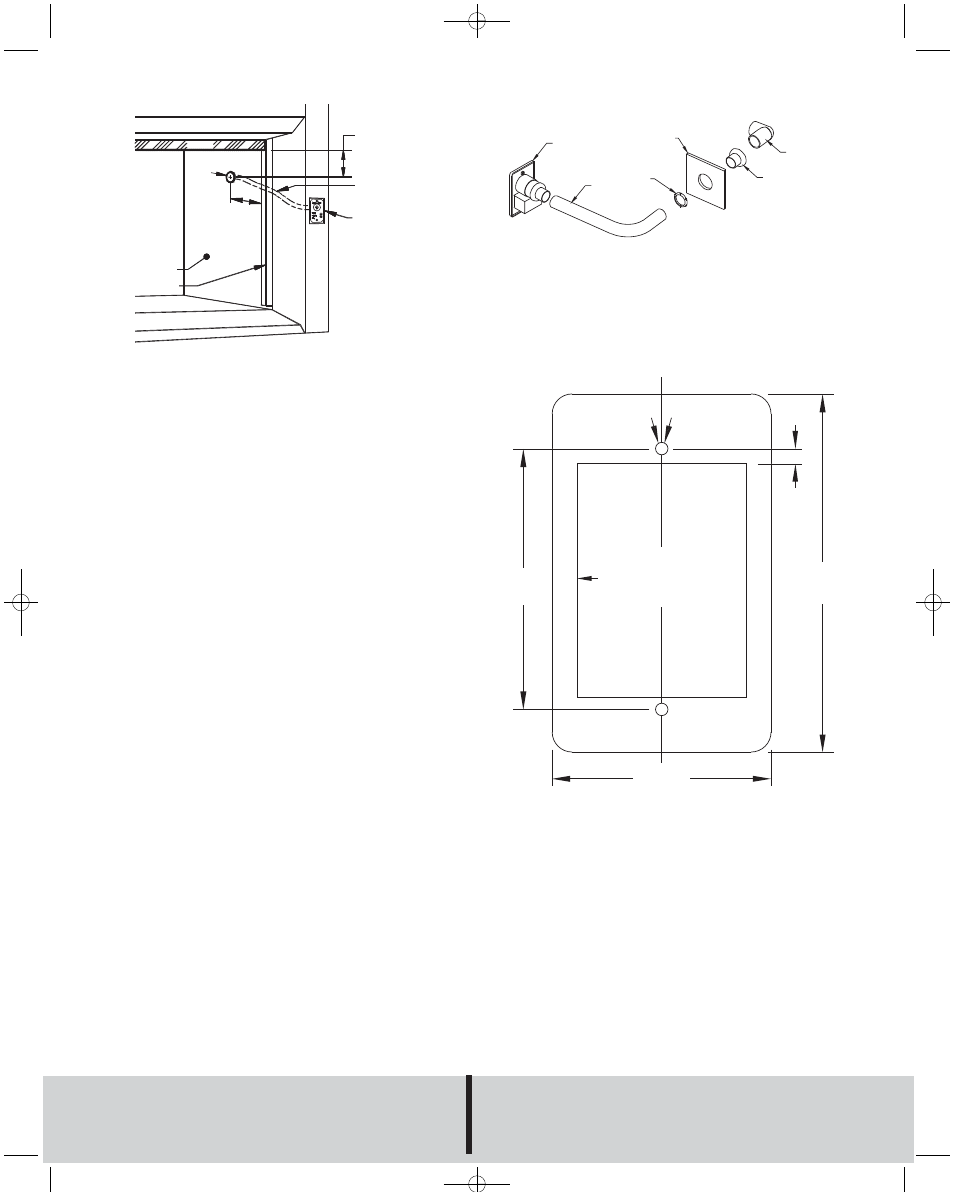

AIR VELOCITY

MONITOR

TUBING

SIDE WALL

SASH TRACK

SASH

OUTLET

HOLE

CENTER OF HOLE 4˝ (101)

BELOW BOTTOM OF

FULL OPEN SASH

4-10˝

(101 - 254)

600 AVM

FUME HOOD WALL

(Ø1.315˝)

TUBING

LOCKNUT

TUBE ADAPTER

OPTIONAL 90

°C

ELBOW ADAPTER

3.275

[83.2]

.187

[4.76]

4.5 REF.

[114.3]

DRILL TO 5/64 (2) FOR

PANEL MOUNTING

USE #6 SHEET

METAL SCREWS

DRILL TO 5/32 (4) FOR

JUNCTION BOX

MOUNTING USE 6-32

MACHINE SCREWS

2.125 X 2.938 (54 X 74.5)

CUTOUT FOR PANEL

MOUNTING

2.75 REF.

[70]

Fig. B

Fig. C

Fig. D

H-16:H-16 7/24/09 10:48 AM Page 2