Dwyer MS2-M User Manual

Page 4

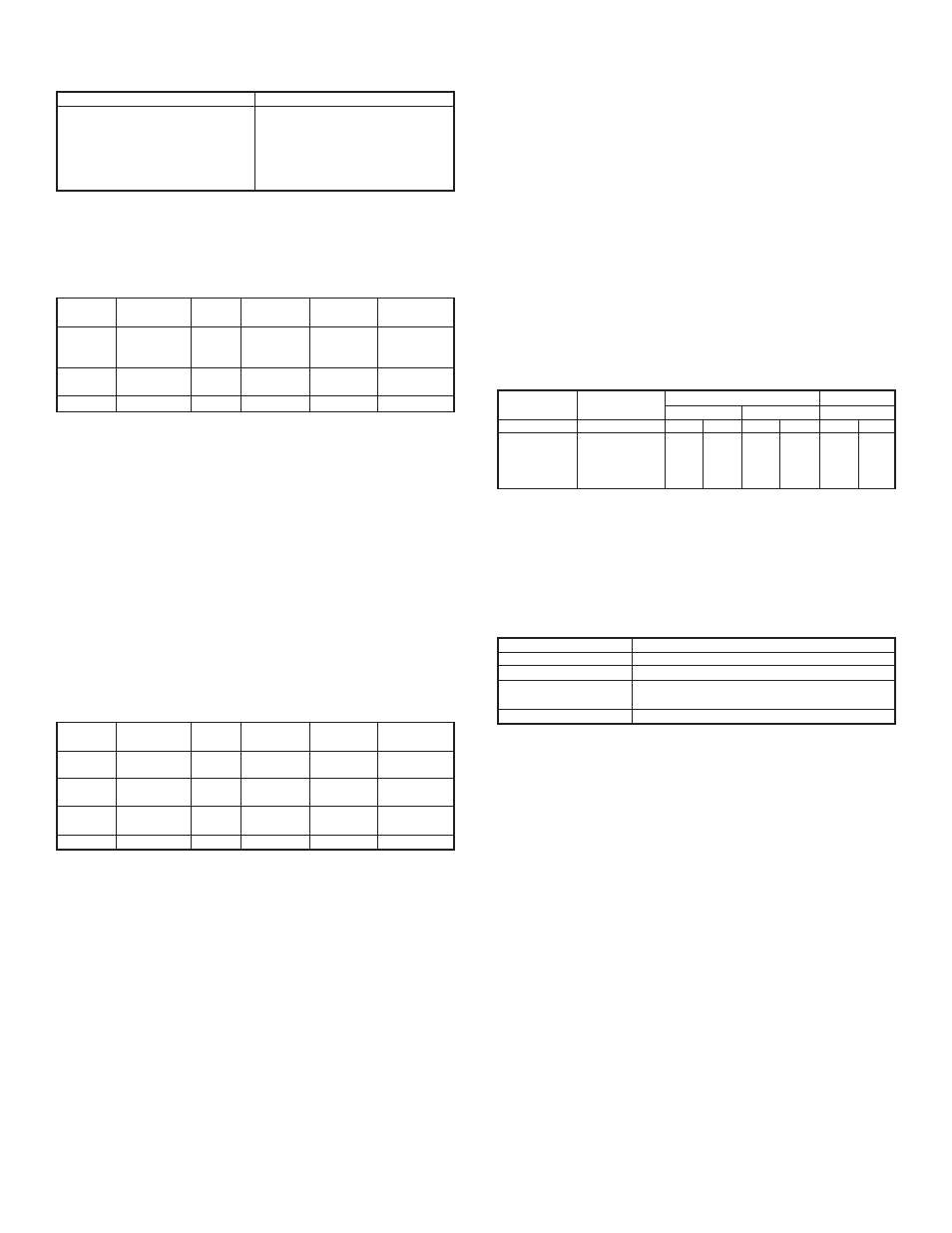

Modbus

®

Communication Protocol functions

The device supports the following functions

The String data type is read as a stream of ASCII characters, with the first character

sent in the MSB of the first register, and the second character sent in the LSB of

the first register and so on. If the string is shorter than the allotted size, the

remaining bytes will be zero padded.

Holding Registers

The holding registers allow configuration of the Velocity K value and Area

associated with velocity and flow calculations. By default, both the Velocity K value

and Area are set to 1.0. In order to read a correct velocity or flow, these values

should be written with appropriate values. The register “Use default K” value

indicates to the device if the values in Velocity K value and Area are valid and

should be used. Set “Use default K” value to 0 in order to use values written to the

Velocity K value and Area registers.

Coils

The coil registers represent functions of the device. The value returned when

reading a coil register indicates the status of the last function execution. If the value

is 1, then the last time the function executed was a success. If the value is 0, then

the function has either not been executed since power on or failed during the last

execution. To execute a function, write 1 to the corresponding register. A response

will be returned immediately and the value of the coil will be set to 0. Once the

function completes, the value of the coil will be set to 1 if the operation was a

success. An application should poll the value of the coil periodically during this time

to determine if the function succeeded. If the coil value does not transition to 1 after

at most 10 seconds, then the operation failed.

Coil 1 – Zero function

The zero function will attempt to recalibrate the zero point. This may be needed if

the pressure sensor has drifted over time. Note that the zero function will only re-

zero the sensor if the current pressure is within ±2% of span pressure of the

previous zero. If the current pressure is outside the valid band, the zero function will

fail and the coil value will remain 0. If the sensor has drifted far enough that the zero

function fails, then pressure will have to be applied to bring the current pressure

closer to the current zero, and the zero function will have to be executed multiple

times until the actual zero is reached.

Coil 2 – Span function

The span function will attempt to recalibrate the maximum positive or negative

pressure. Note that accurate span pressure depends on an accurate zero pressure.

The span function will fail if the zero function has not been executed within the last

5 minutes.

Coil 3 – Reset factory Defaults function

The reset factory defaults function resets the zero, span, Velocity K value, Area,

and Use Default K Value variables back to their factory default values.

Coil 4 – Reset Device function

The reset device function allows this device to be reset remotely from Modbus

®

.

When the reset device function coil is written with a value of 1, the device will

immediately respond with success. The reset will take place approximately 5

seconds after the command was received. Writing the value 0 to this coil has no

effect.

Multi-address Support

Multi-Address support allows a register to be read or written to using different byte

orientations specified by the address range. For example, input register 0003 can

also be read at 2003, 4003 and 6003 with different byte orientations as listed in the

below table. Registers that do not have multi-address support are only available in

Big-Endian byte orientation (Modbus

®

Communication Protocol standard).

LeD Status

The device provides three LEDs to indicate status and activity. The LEDs are

located to the right of the terminal block and are arranged from left to right as green,

yellow, and red. The green LED indicates communication with the pressure sensor.

This LED will flash very quickly most of the time, even without requests from the

Modbus

®

interface. The yellow LED indicates Modbus

®

communication addressed

to this specific device. The frequency and duration of this LED depends on the baud

rate and size of request sent. The red LED indicates error states by flashing specific

error codes periodically.

MaINTeNaNCe/RePaIR

Upon final installation of the Series MS2 Differential Pressure Transmitter, no

routine maintenance is required. The Series MS2 is not field serviceable and it is

not possible to repair the unit. Field repair should not be attempted and may void

warranty.

WaRRaNTY/ReTURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem

plus any additional application notes.

function Name

Read Coils

Read Holding Registers

Read Input Registers

Write Single Coil

Write Single Register

Write Multiple Registers

function Code

01

03

04

05

06

16

Register

0001

0002-0003

0004-0005

Description

Use default K

value. (Default

value: 1)

Velocity K

value

Area (ft

2

)

Data

Type

Unsigned

16 bit

integer

Float

Float

Value

0...1

0...9.999

0.01...999.99

Range

False-True

0...9.999

0.01...999.99

Multi-address

Supported

Yes

Yes

Yes

Register

0001

0002

0003

0004

Description

Perform Zero

function

Perform Span

function

Reset Factory

Defaults

Reset Device

Data

Type

Boolean

Boolean

Boolean

Boolean

Value

0...1

0...1

0...1

0...1

Range

False-True

False-True

False-True

False-True

Multi-address

Supported

No

No

No

No

Byte Order

Big-Endian

Byte Swap

Word Swap

Little-Endian

address Range

1 – 2000

2001 – 4000

4001 – 6000

6001 – 8000

float/32Bit Values

Register 1

MSB

A

B

C

D

B

A

D

C

Register 2

C

D

A

B

LSB

D

C

B

A

16Bit Values

Register 1

MSB

A

B

A

B

LSB

B

A

B

A

Number of flashes

Solid On (not flashing)

1

2

3

error Description

Invalid Factory Configuration

Invalid Modbus

®

Communication Protocol Address

Intelligent Serial Configuration in progress, unit may

not respond to requests

Communication with pressure sensor failed