Dwyer 3100MP User Manual

Page 5

Page 4

Chapter 2 Handling Cautions

This chapter consists of cautions for transmitter handling, storage,

installation, insulation and explosion structure, etc.

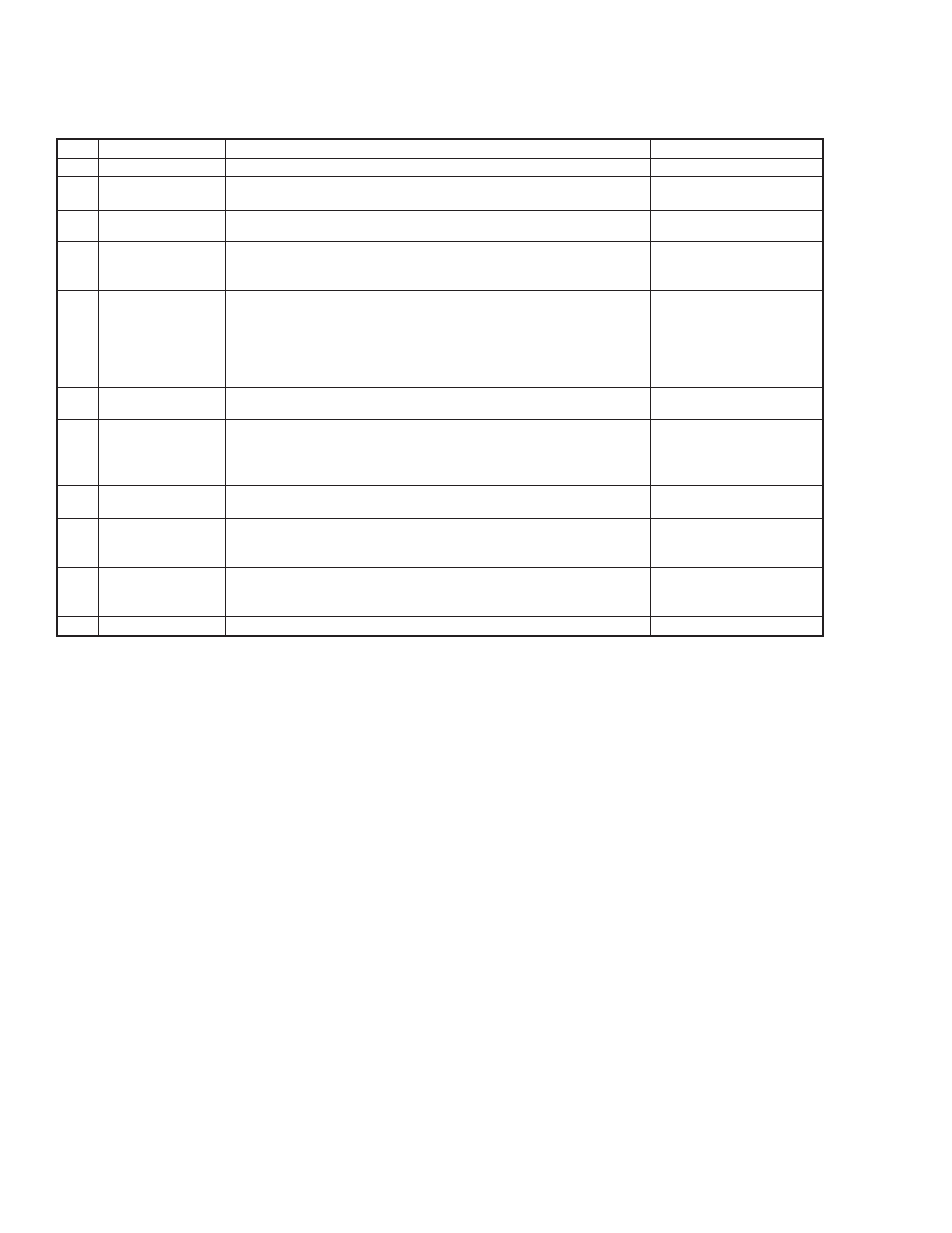

Step

1

2

3

4

5

6

7

8

9

10

11

Job

Unpacking

Model and

Specifications

Storage

Calibration

Installation

Locations

Mechanical

Considerations

Electrical

Considerations

Mounting and

Installation

Calibration on Spot

Pressure

Operation

Job Details

- Unpack transmitter packing

- Make sure the transmitter nameplate matches the model number

on the P.O.

- In a dry, non-vibration and non-impact area

- Ambient temperature around 77°F (25°C) and 65% relative humidity

- Configuration of the Range, Zero/Span, Unit, Tag, Dampening

Time, Transfer Function, DA Trim and other parameters

- Where ambient temperature are constant

- Exposure to chemical corrosion, etc.

- Where shock and vibration are minimal

- Where the area classification does not exceed the explosion-proof

rating

- Where maintenance is easy

- Where the transmitter can be handled easily

- Be cautious of process connections leaking

- 24 VDC

(Power Supply is 11.9 Vdc – 45 Vdc)

- For HART

®

communication, resistance on transmitter terminal loop

should be between 250 – 550 Ohms

- When mounting the transmitter, an appropriate bracket should be used

- The transmitter should be mounted securely to prevent swing

- Sensor Zero Trim should be done ten seconds after differential

pressure stabilizes

- Make sure that PV value is zero and current is 4 mA

- Do not apply a regulated differential pressure and line pressure

- Close the equalizing valve on the 3 valve manifold and then open

the valve on high and low side slowly and simultaneously

- Make sure the transmitter operates properly

Instrument

- HHT

- Pressure Source

- Galvanometer

(Engineering)

(Engineering)

(Engineering)

(Mounting and Installation)

HHT or

Zero/Span button

(Applying pressure)

Eye or HHT