Dwyer 629 User Manual

Page 2

INSTALLATION

1. Location: Select a location where the temperature of the unit will be

between 0°F and 175°F. Distance from the receiver is limited only by

total loop resistance (see electrical connections).The tubing feeding

pressure to the instrument can be practically any length required, but

long lengths will increase the response time slightly. Mount the

instrument in a location that will not be subject to excessive temperature,

shock or vibration.

2. Position: A vertical position is recommended (pressure connections

pointing horizontally) since that is how all standard models were

originally spanned and zeroed at the factory. They can be used at other

angles, but may require final spanning and zeroing. Due to potential

condensation build up that may travel down conduit or cable and into the

housing, it is recommended to install with the electrical conduit or cable

gland pointing downward.

3. Pressure Connection: Dual 1/4˝ female NPT pressure connections

are provided. Use pipe thread sealant tape or other suitable pipe joint

compound when making connection to the pressure source. Avoid

excess sealant which could block the pressure passage. When

monitoring liquid pressures, air trapped in the lines can cause incorrect

readings. Bleed fittings or similar mechanisms should be used to bleed

off any trapped air.

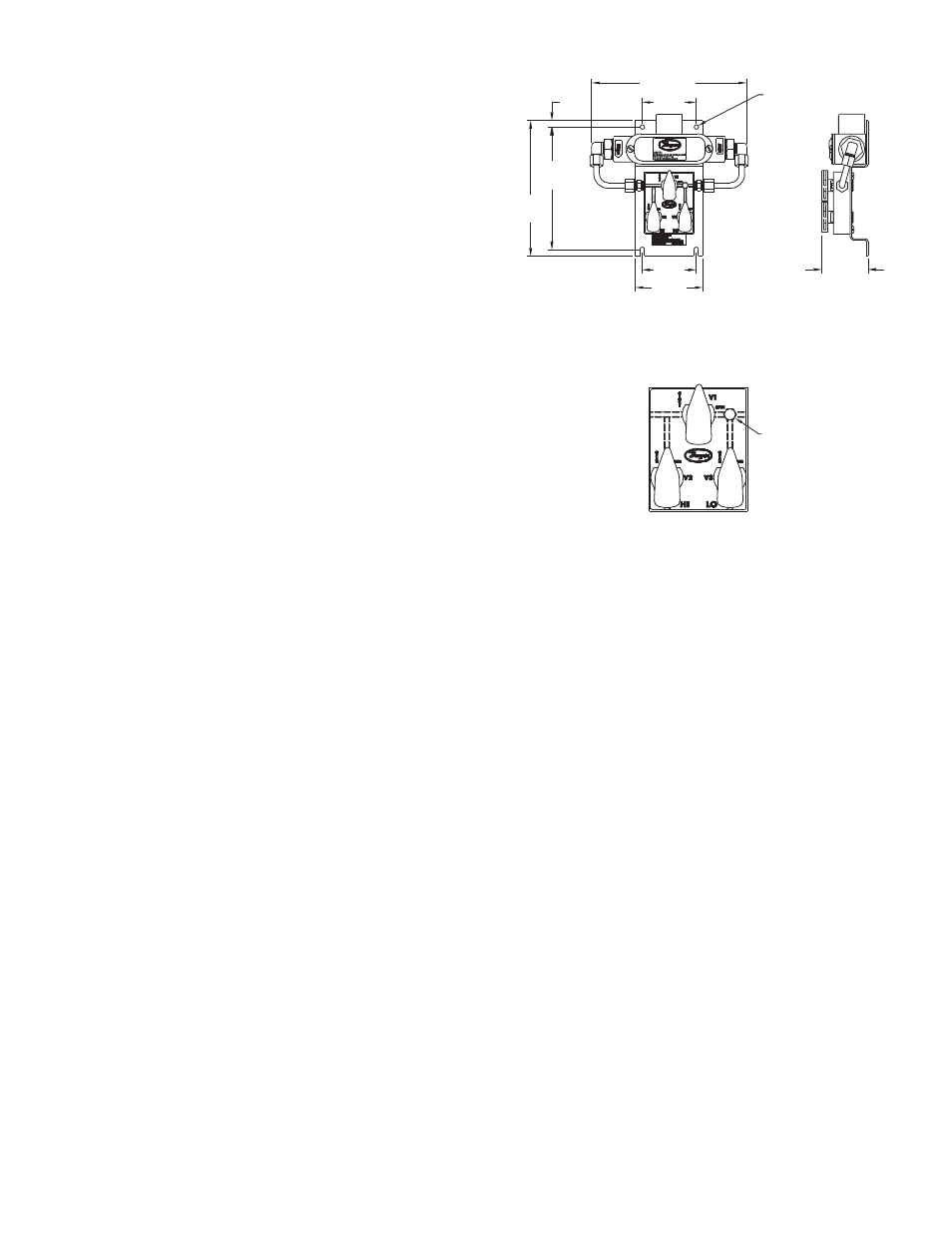

Optional 3-Way Valve

For applications where higher line pressures may be encountered at

installation or when it is necessary to remove the transmitter for

maintenance without interrupting the process, the optional three way

valve is recommended (See Fig. A).

Begin with valve V1 open and valves V2 and V3 closed (See Fig. B).

Slowly open valves V2 and V3. Once the pressure has stabilized and is

equal on the high and low side of the transmitter, valve V1 can be closed

and normal operation can proceed.

To ensure proper pressures will be detected by the 629 use the bleed

fitting provided with this package to free media of bubbles. Before

applying pressure to the process connections, turn V1 to the open

position and back off the bleed screw. Next apply pressure. After the

flowing liquid is free of bubbles, retighten the bleed screw.

Before removing the transmitter from operation, open valve V1 then

close valves V2 and V3.

Fig. A

Fig. B

9/32

[7.14]

6-29/32

[175.42]

2.400

[60.69]

5-7/16

[138.11]

6-1/64

[152.81]

3

[76.20]

2.400

[60.69]

2-1/16

[52.39]

Ø13/64 [5.64] DIA

MOUNTING HOLES

TYP 4 PLACES

B

BLEED SCREW