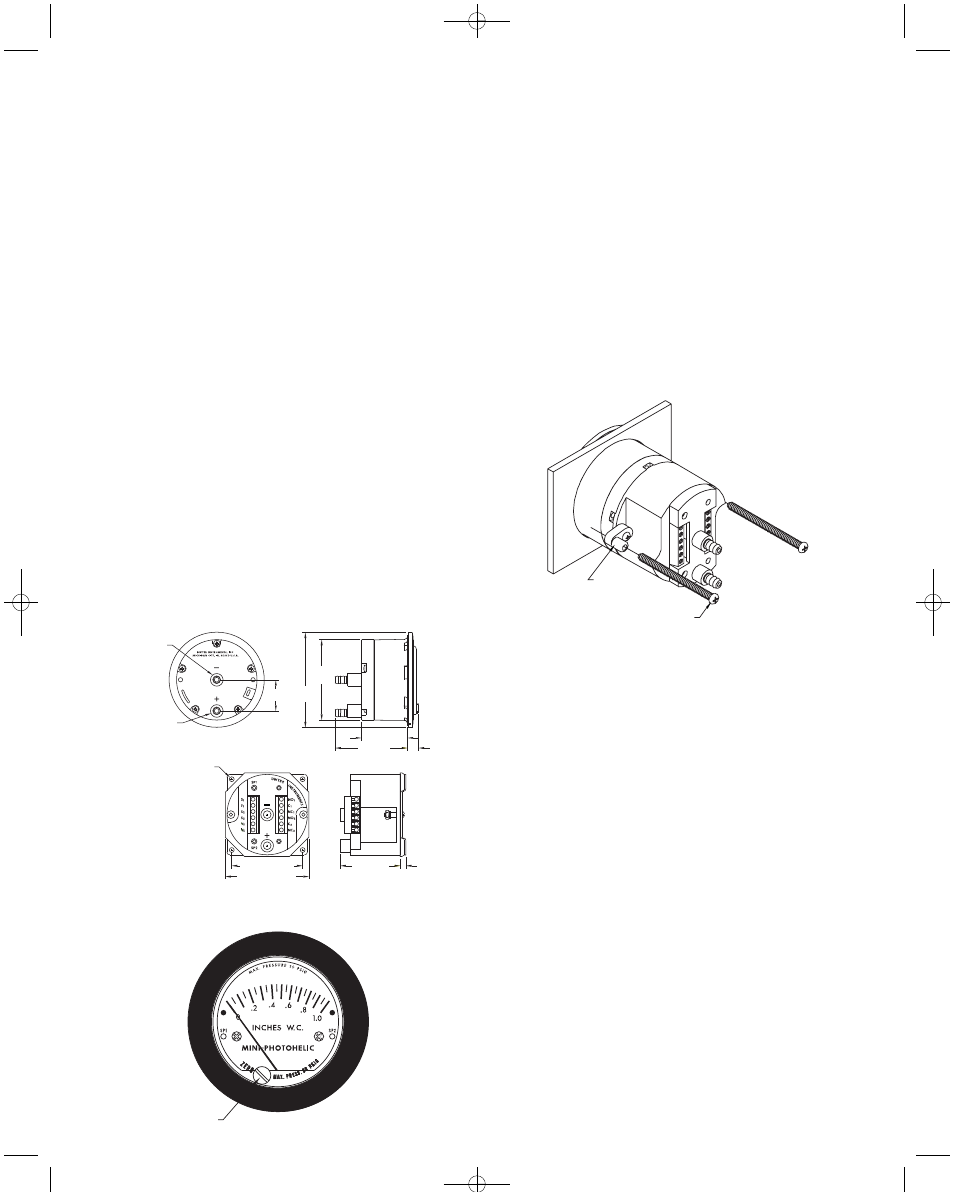

Installation, Fig. a, Fig. b – Dwyer MP User Manual

Page 2

INSTALLATION

1. Location: Select a location free from excessive

vibration and where ambient temperature will be

between 20 to 120ºF (-6.7 to 49ºC). Pressure sensing

lines may be any length necessary without affecting

accuracy. However, long runs of tubing will dampen

readings slightly and cause an increase in response

time. If pulsing pressure or vibration cause excessive

pointer oscillation please contact factory for ways to pro-

vide additional damping.

2. Position: The Mini-Photohelic

®

is calibrated and zeroed

with gage face in the vertical position at the factory. If the

gage is used in any other position, it must be re-zeroed

each time the position is changed. Gages with ranges

under 5 in. w.c. (1.24 kPa), or equivalent, should be

used only in the vertical position unless special calibra-

tion was specified when ordering.

3. Mounting: The Mini-Photohelic

®

is normally mounted

before making electrical connections. Terminal blocks

are located on the rear of the gage for electrical connec-

tions.

(A) Panel Mounting: Standard installation for the Mini-

Photohelic

®

mounting is flush through a panel.

Allow approximately 1˝ clearance for pressure tub-

ing and electrical wiring. cut a 2-5/8˝ (66.68 mm)

diameter hole in the panel. Insert the Mini-

Photohelic

®

into the panel, thread #6 mounting

screws into the mounting lugs and tighten.

4. Zeroing: Before installation, the Mini-Photohelic

®

may

need to be zeroed before placing into operation. If

zeroing is required, you must first remove the zero

adjust plug, located near the bottom face of the gage,

with a small blade screwdriver. (refer to Fig B.) The

zero adjust screw is located directly behind the plug.

Use the hex allen wrench supplied and adjust until the

pointer is on zero. This must be done with both pres-

sure connections vented to the atmosphere and the

gage oriented in the final mounting position. Replace

plug. Caution must be taken not to overtighten the

plastic plug when repluging.

5. Pneumatic Connections: To measure positive pres-

sure, connect tubing to port marked “+” and vent “–”

port to atmosphere. For negative pressure (vacuum),

connect to port marked “–” and vent “+” port to atmos-

phere. If gage is supplied with 1/8˝ male NPT connec-

tions careful attention must be made not to over-tight-

en fittings to avoid damage to the gage.

1 (25.40)

LOW PRESSURE PORT

HIGH PRESSURE PORT

2-19/32

(65.88)

3-1/16

(77.79)

1-7/16

(36.51)

2-3/8

(60.33)

23/64

(9.13)

1-15/16

(49.21)

11/64

(4.37)

5/32 (3.97)

MOUNTING HOLE

TYP 4 PLACES

2.276 (57.81) TYP

2-11/16 (68.26) SQ

Fig. A

ZERO ADJUST PLUG

Fig. B

PANEL MOUNTED

#6 MOUNTING

SCREW

MOUNTING

LUG

B-37-A:B-37-A 9/29/09 9:37 PM Page 2