Crystal GaugeCalXP Rebuild Kit User Manual

Page 3

GaugeCal

XP

Service Instruction Sheet

•

Page 3

C R Y S T A L

engineering corporation

12

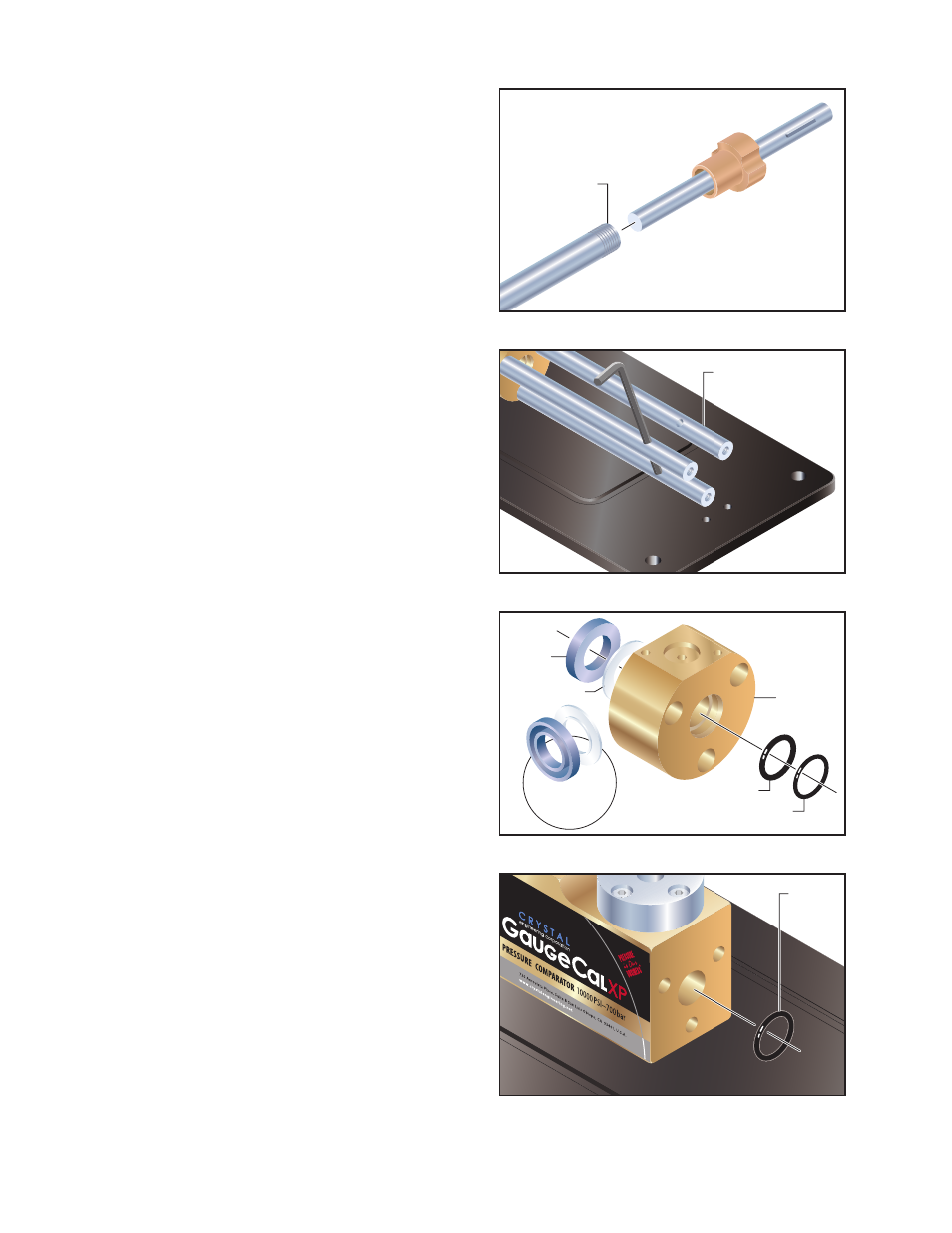

To remove the three (3) stainless steel Guide

Rods, insert the 4mm Allen key into the hole

in the side of each rod, and then pull to the

left (counter-clockwise) to loosen and un-

screw each one (figure 9).

When the final Guide Rod has been re-

moved, the Main Seal Block will fall away

from the Manifold Block.

13

From the front of the Main Seal Block,

remove the o-ring (

PN

3131) and the back-

up ring (

PN

3151) (figure 10).

14

From the rear of the Main Seal Block, remove

the Rod Seal (

PN

3152) and Rod Seal Backup

(

PN

3434) (figure 10).

Note:

When rebuilding the Main Seal Block

assembly, Dow Corning

®

111, or a similar

silicone-based lubricant, must be applied

to the grooved surface of the Rod Seal (

PN

3152).

When the Rod Seal is installed, its flat sur-

face should face toward the Main Seal Block,

while its grooved surface faces out to mate

with the Manifold Block (figure 10).

15

From the front of the Manifold Block,

remove the Main Seal Block o-ring (

PN

3418)

(figure 11).

Note:

When re-attaching the Main Seal

Block and Guide Rods to the Manifold Block,

you may find it easier to first remove the

Manifold Block from the Baseplate.

From the underside of the Baseplate, use a

4mm Allen key to remove the four (4) cap

screws holding the Manifold Block in place.

Use the three (3) Guide Rods to attach the

Main Seal Block to the Manifold Block, then

re-attach the Manifold Block to the Base-

plate before attaching the Piston Assembly

and Bearing Block.

Figure 8

Figure 9

Figure 10

Figure 11

Piston

Shaft

Guide Rod

Rod Seal and

Backup shown

rotated 90°

Rod Seal

(

PN

3152)

Rod Seal Backup

(

PN

3434)

Main Seal

Block

O-ring

(

PN

3131)

Backup ring

(

PN

3151)

O-ring

(

PN

3418)