Crystal DiffXP User Manual

Differential pressure test set, User instructions, Overview

Differential Pressure Test Set

User Instructions

Overview

Using Crystal Engineering’s Differential Test Set based XP2i-

DD and XP2i gauges, it’s possible to perform pressure differ-

ential measurements. By simply connecting your upstream

(+) and downstream (–) pressure lines to the 1/8” FNPT fittings

you are ready to go. This test set is capable of displaying

live or average differential pressures (average of 10 samples)

depending upon which display mode you select.

Operation

A typical differential pressure measurement may be done in

the following manner.

1

Select Units:

Select your required unit of pressure mea-

surement on each gauge by pressing the

units

button

on each gauge independently. You may select different

units for each gauge but they must be set individually. The

differential pressure will be displayed on the lower line of

the right (–) dual display gauge and will be in the same

units as the static pressure.

2

Select Display Options:

Select the appropriate display

option on each unit using the

peak

button:

a

Right hand (–) or differential pressure gauge:

Using

the

peak

button, select live pressure display (both

HI

and

LO

icons), or Average pressure over 10 read-

ings (both

HI

,

LO

, and AVG icons). Static pressure will

be display on the primary line and the differential pres-

sure will be displayed on the secondary or lower line;

i

If averaging mode is selected, the lower line will

display the averaged differential pressure regardless

of what display mode the left hand (+) gauge is in.

ii

When only the AVG icon is lit, the second line display is

the averaged non-differential reading from the gauge

and may not be appropriate for your application.

b

Left hand (+) or upstream gauge:

Using the

peak

button, select live pressure readings (no HI or LO icons),

or Average pressure over 10 reading (both

HI

and

LO

icons).

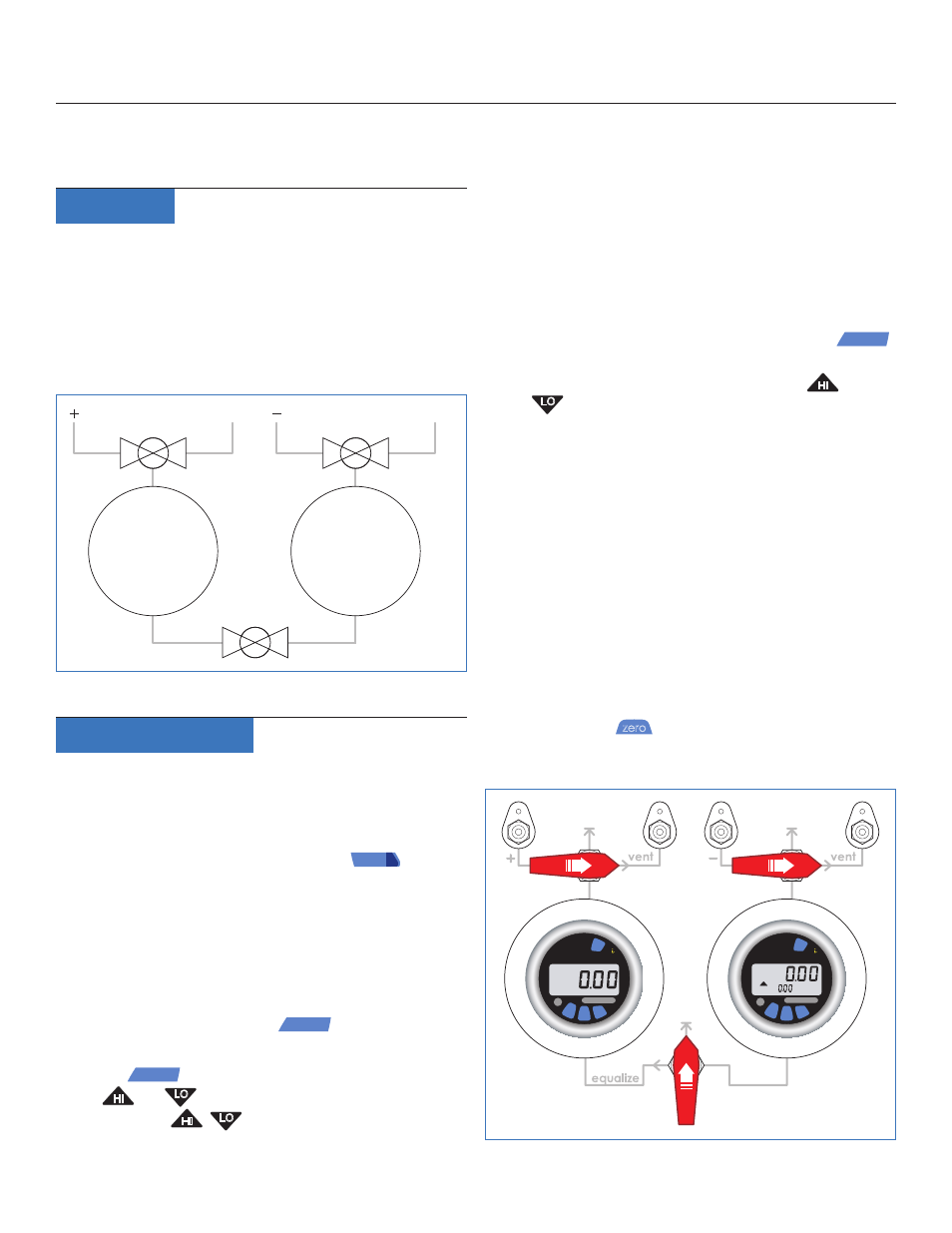

3

Pressure Connections:

Connect upstream (+), down-

stream (–), and their corresponding vent lines to the four

1/8” FNPT connection ports located near the hinge of case.

Use pipe thread tape or pipe thread sealant as necessary to

ensure a leak free connection.

a

Always use a wrench on the test set bulkhead

1

/

8

" FNPT

fitting, as there is a limit to how much rotational force

can be applied to the case.

b

Due to the robust nature of the Crystal XP2I gauges, full

scale pressure may be applied to either gauge at any

time without damage.

4

Zero Gauges:

Zero both gauges in the vented condition

by pressing the

zero

button on each gauge. Figure 2

illustrates the appropriate valve states to ensure venting

and isolation between both gauges.

C R Y S T A L

XP

2

C R Y S T A L

XP

2

HI

Figure 1: General piping interconnect diagram.

Figure 2: Zero gauge valve states.

© 2007 Crystal Engineering Corporation 708 Fiero Lane, Suite 9, San Luis Obispo, California 93401-8701

Single-

or Dual-line

display

vent

vent

Dual-line

display

(Second line is

DP Measurement)