Installation instructions, single support, Installation instructions, double support – Badger Meter Ellipse Model PFA User Manual

Page 5

INSTALLATION INSTRUCTIONS, SINGLE SUPPORT

1 . Choose the proper location to install the PFA Fire Pump System Ellipse using AGA/ASME standards (or equivalent) . See

“Preso Ellipse Location Instructions” on page 7

2 . Grind the surface of the pipe where the PFA Fire Pump System Ellipse is to be inserted to provide a clean area for welding .

3 . Weld the supplied weld-o-let to the pipe using standard codes for your application (1/16" weld gap recommended) .

Take care to protect the threads during the welding process .

4 . Drill a hole through the pipe wall according to

.

5 . Deburr the hole just drilled, especially on the inside of the pipe .

Pipe Size

Model / Sensor

Weld Connector

Drill Bit

2…5 in .

PFA (1/2")

1/2"

5/8"

6…12 in .

PFA (7/8")

1"

1-1/8"

14…16 in .

PFA (1-1/4")

1-1/4"

1-3/8"

Table 2: Single support drill bit size

6 . Install the supplied compression fitting by threading it into the weld-o-let manually . Then with a wrench, tighten the

fitting another 1-1/4 turns, taking care not to tighten the compression nut .

7 . Install the instrument valves at the PFA Fire Pump System Ellipse head connections . Make sure the valves are FULLY

CLOSED to prevent them from leaking during startup .

8 . Insert the PFA Fire Pump System Ellipse through the compression fitting . See

. Carefully push the sensor by hand

further into the pipe until it reaches the opposite wall .

9 . While holding the PFA Fire Pump System Ellipse in its fully inserted position, align the arrow located on the sensor head

with the direction of flow . See

10 . Thoroughly tighten the compression nut in order to prevent leakage . After tightening the compression nut manually, turn

it another 1-1/4 turns with a wrench .

INSTALLATION INSTRUCTIONS, DOUBLE SUPPORT

1 . Follow steps 1 through 7 in

“Installation Instructions, Single Support”

. At 180° from and on the same plane as the previously

drilled hole, grind the surface of the pipe to provide a clean area for welding . Drill a hole and deburr, especially on the

inside of the pipe . The hole used for the double support should be sized according to

.

2 . Weld the double support weld-o-let making sure that it is centered with the drilled hole (1/16" weld gap recommended) .

3 . Install the PFA Fire Pump System Ellipse sensor through the two holes . Make sure that the double support pin passes

through the guide ring . See

.

4 . Align the arrow located on the sensor head in the direction of flow as in step 9,

“Installation Instructions, Single Support”

.

5 . Ensure that the PFA Fire Pump System Ellipse is in the correct orientation and spans the inside of the pipe . Tighten the

compression nut . After tightening the compression nut manually, tighten it 1-1/4 turns more using a wrench .

6 . Install the plug into the end of the double support weld-o-let . Tighten the plug to prevent leakage .

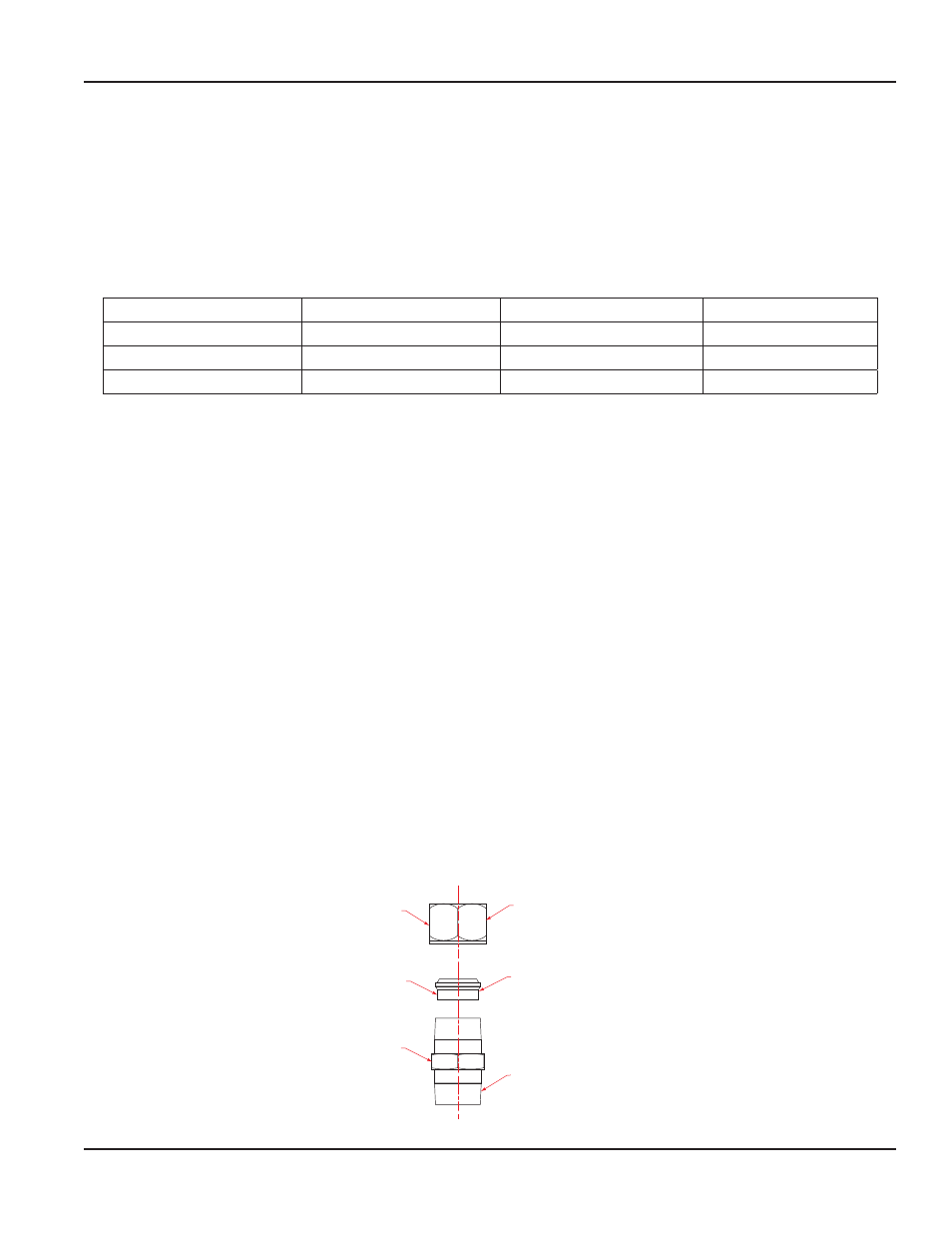

Threaded portion

to be installed

into weld fitting

on pipe

Install insert

as shown

Thread nut loosely

onto body of the

compression fitting

Body

Insert

Nut

Figure 4: Compression fitting assembly

User Manual

Page 5

April 2014