Installation instructions, double support, Figure 5 – Badger Meter AHL-GD - Hot Tap, High Pressure (2 to 72")" User Manual

Page 6

Ellipse® Pitot Tube Meter, AHL-GD Differential Pressure Flow Meter

Page 6

April 2014

INSTALLATION INSTRUCTIONS, DOUBLE SUPPORT

1 . Follow steps 1 through 6 in the single support section . At 180° from and on the same plane as the previously drilled hole,

grind the surface of the pipe to provide a clean area for welding . Drill a hole and de-burr, especially on the inside of the

pipe . The hole used for the double support should be sized according to

Model/Sensor

Weld Connector

Drill Bit

AHL-GD (7⁄8 in .)

1/8 in .

3/8 in .

AHL-GD(1-1/4 in .)

1 in .

7⁄8 in .

Table 3: Double support drill bit size

2 . Weld the double support thread-o-let making sure that it is centered with the drilled hole (1/16 in . weld

gap recommended) .

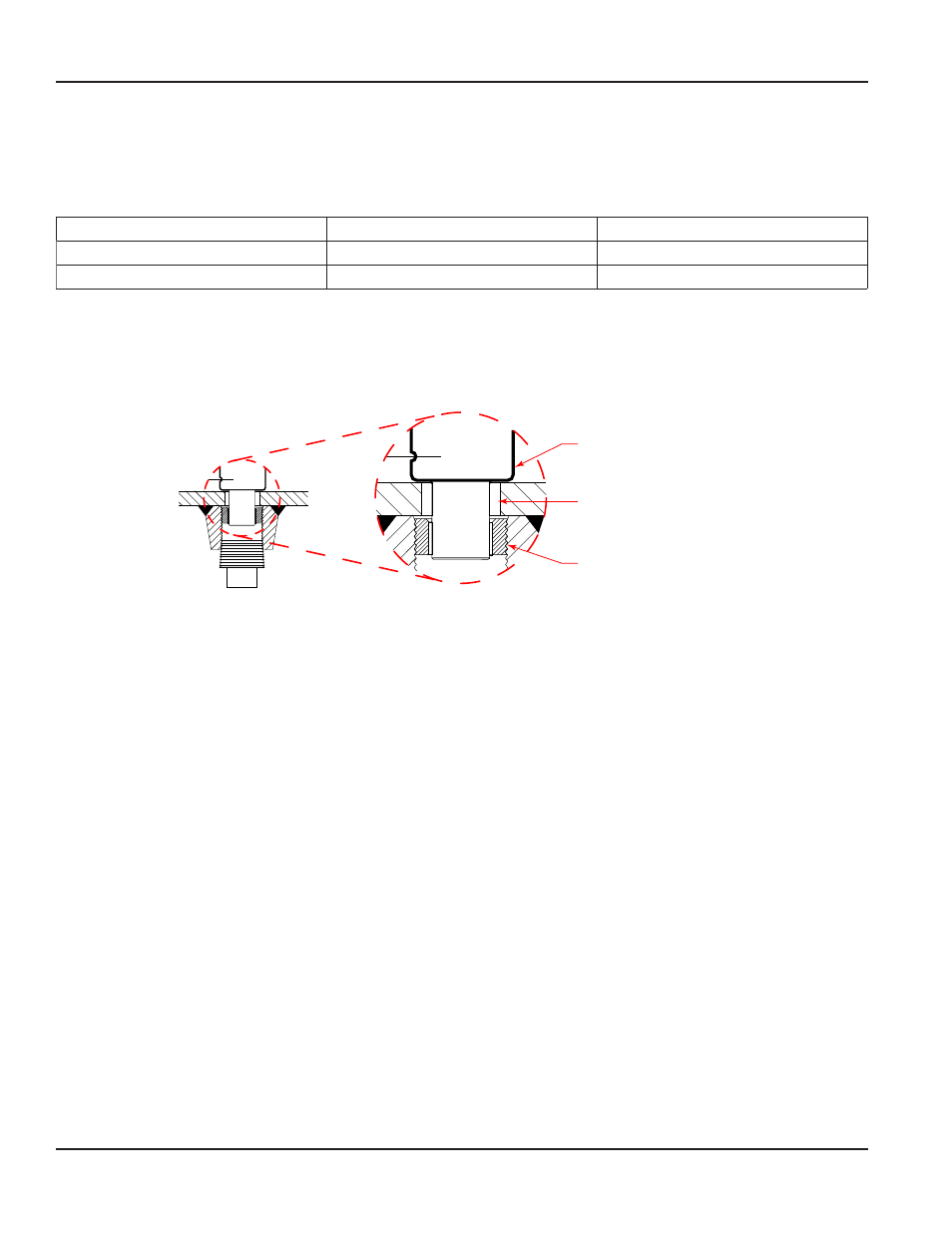

3 . Install the AHL-GD Differential Pressure Flow Meter sensor through the two holes . Make sure that the double support pin

passes through the guide ring . See

.

Ellipse Sensor

Double Support Pin

Guide Ring

Figure 5: Double support installation

4 . Align the arrow located on the sensor head in the direction of flow as shown in

.

5 . Ensure that the AHL-GD Differential Pressure Flow Meter is in the correct orientation and spans the inside of the pipe .

Tighten the threaded insertion rods until the sensor reaches the other end of the pipe .

6 . Install the plug into the end of the double support thread-o-let . Tighten the plug to prevent leakage .