Installation instructions, single support – Badger Meter AF - Flanged (2 to 120")" User Manual

Page 5

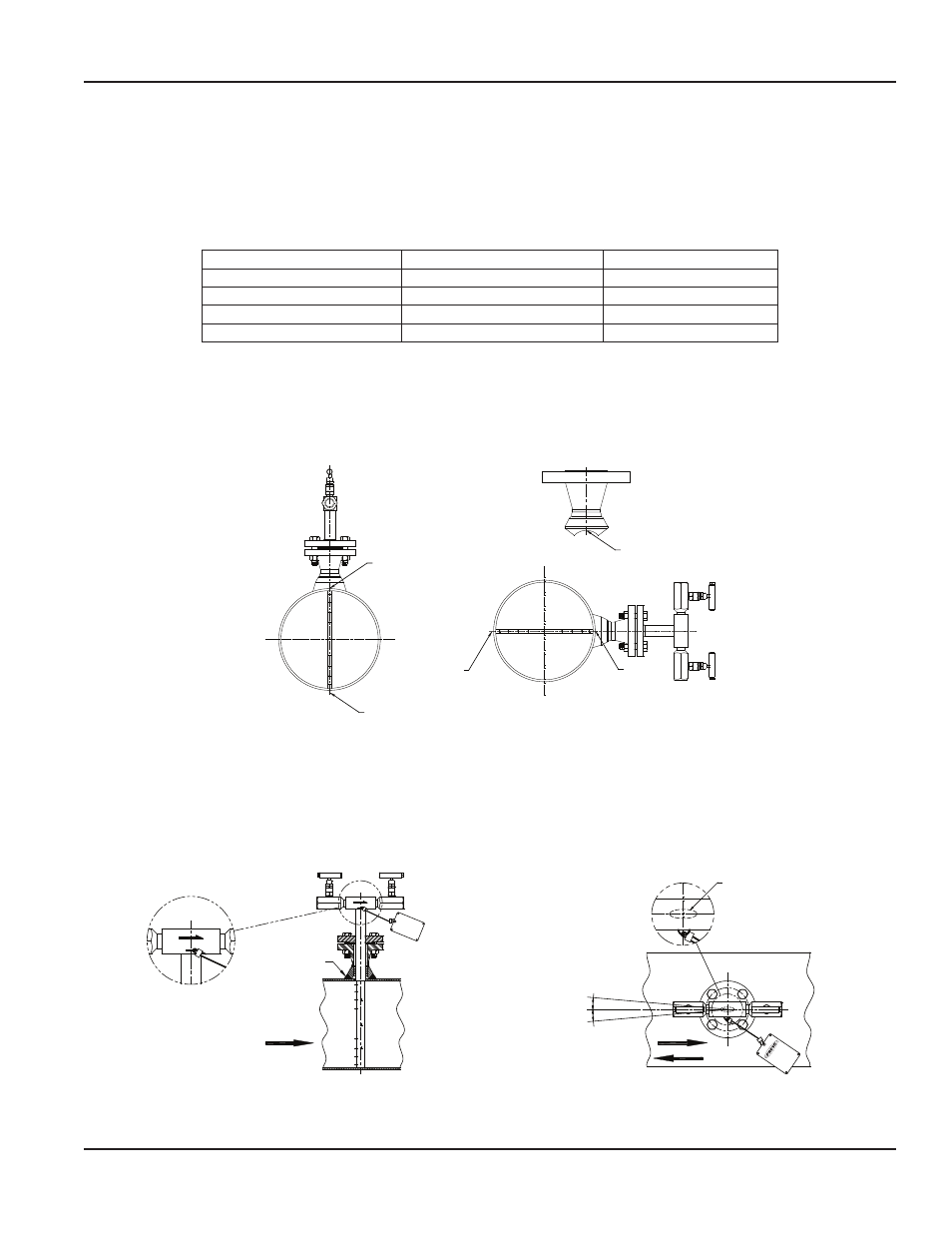

INSTALLATION INSTRUCTIONS, SINGLE SUPPORT

1 . Choose the proper location to install the AF Ellipse using AGA/ASME standards (or equivalent) . See

2 . Grind the surface of the pipe where the AF Ellipse is to be inserted to provide a clean area for welding .

3 . Drill a hole through the pipe wall according to

.

Model / Sensor

Weld Connector

Drill Bit

AF0 (1/2")

3/4"

5/8"

AF (7/8")

1-1/4"

1-1/8"

AF1 (1-1/4")

1-1/2"

1-3/8"

AF2 (2-1/4")

3"

2-3/4"

Table 2: Single support drill bit size

4 . Deburr the hole just drilled, especially on the inside of the pipe .

5 . Weld the mounting hardware assembly to the pipe, centered on the drilled hole, using standard codes for your

application (1/16" weld gap recommended) . Align low point of radius on bottom of weld-o-let so that it is in line with the

pipe centerline .

L

H

Low Point

of Radius

Low Point

of Radius

Low Point

of Radius

Horizontal

Vertical

Pipe

Centerline

Pipe

Centerline

Figure 4: Weld alignment

6 . Install the gasket and place the AF Ellipse sensor into the pipe .

7 . While holding the AF Ellipse in its fully inserted position, align the arrow on the sensor head with the direction of flow . See

H

L

Field Weld

Flow

5° MAX

5° MAX

Ellipse

Flow

Flo

w M

et

ers

Figure 5: Sensor alignment

8 . Thoroughly tighten all of the bolts on the flange and assemble all the parts that make the instrument head .

User Manual

Page 5

April 2014