Introduction, Specifications – Badger Meter AF - Flanged (2 to 120")" User Manual

Page 3

INTRODUCTION

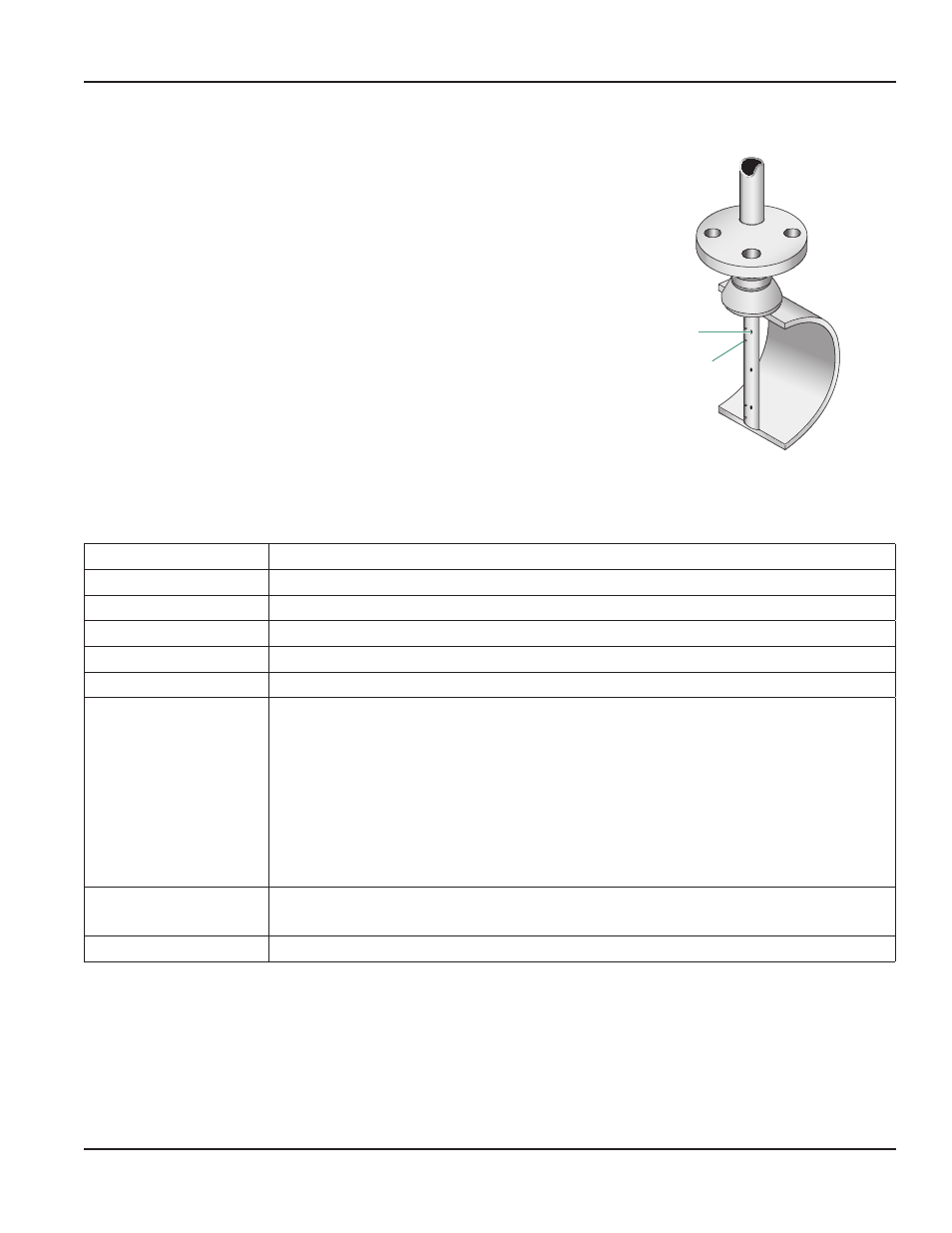

The Preso patented elliptical design outperforms and provides greater

accuracy than traditional differential pressure flow measurement devices . This

differential pressure flow meter is designed with a series of ports facing the

upstream velocity pressures, as well as flow sensing ports strategically located

ahead of the trailing edge flow separation .

The multi-ported, self-averaging flow element consists of an elliptical shape

with two independent flow sensing chambers . The impact velocity sensing

holes (high pressure) are located along the leading edge and the true static

sensing holes (low pressure) are on the exterior probe side . Model AF comes

with instrument shutoff valves with provisions to accept a transmitter or direct

indicating meter .

True static

sensing holes

Impact velocity

sensing holes

SPECIFICATIONS

Applications

Air, liquids and gases

Pipe Sizes

2…72 inches (50…1820 mm)

Pressure

Vary per flange ratings

Temperature

Vary per flange ratings

Accuracy

±0 .75% of reading

Turndown Ratio

17:1 with no vacuum effect

Standard Components

T-type head, 316 SS 1/4" or 1/2" FNPT connection

CS 3000 lb weld fitting, ASTM A105

316/316L SS Ellipse sensor

Instrument valves (2 per sensor), 1/2", CS

316 SS ID tag with wire

150 lb 316/316L SS sensor flange

CS gasket with SS spiral wound ring

CS mounting flange, 150 lb ASTM A-105 with nuts and bolts

Reynolds Number

Greater than 75,000 maintains most accurate flow measurements

Less than 75,000 consult factory for estimated results

Resonance

If greater than 0 .8, use double support per ASME PTC 19 .3

Table 1: Specifications

User Manual

Page 3

April 2014