Dwm 2000 l - installation – KROHNE DWM 1000-2000 EN User Manual

Page 9

DWM 2000 L - Installation

9

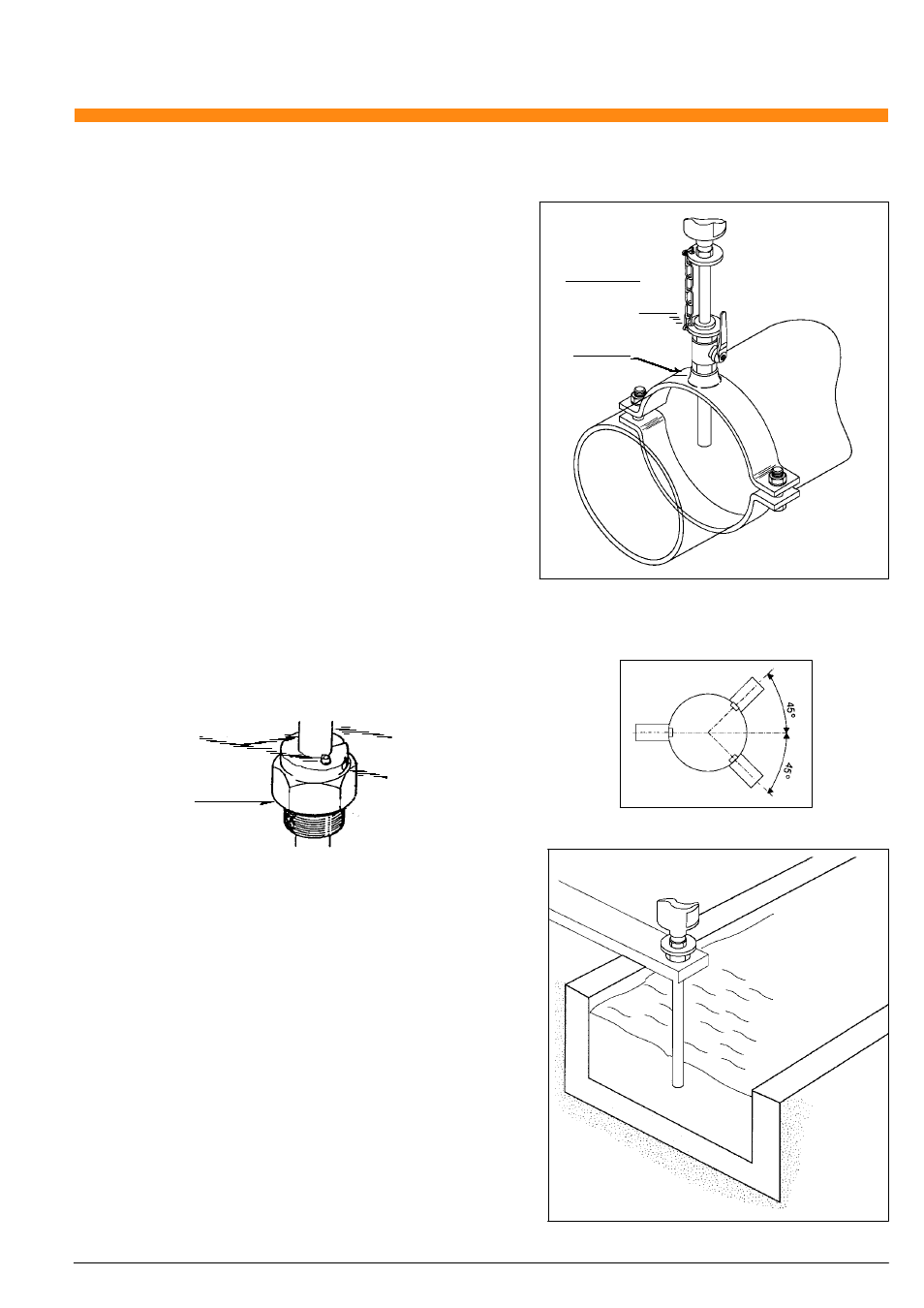

A. Installation on Flow Pipes

n The straight line flow distance required between the DWM and an ups-

tream flow disturbance (inlet, pump, elbow etc) is advised to be 10 x

DN and 5 x DN from downstream disturbances.

n Position the pipe saddle or the welding socket as indicated in the ins-

tallation sketch.

n Screw the ball valve onto the welding socket (or connection flange

according to the saddle design). The valve thread is 1''1/2.

n Ensure that the ball valve is closed.

n Screw the adjustable fitting onto the ball valve.

n Slide the DMW2000/L into the adjustable fitting to a depth of between

60 et 75mm. This assures that the mounting will be watertight.

n The security chain is supplied to the required length as determined for

each application. This length cannot be extended, but may be shorte-

ned where necessary.

n Loosen screw (No. 2 in sketch below) sligthly. This enables the

DWM2000/L to be inserted further without any leakage.

n Open the ball valve.

n Calculate the penetration length (= 1/8 DN Nominal Diameter) with a

tolerance of +2mm - 0mm.

n If flow is heavily perturbated or the internal diameter is uncertain, it is

advised to penetrate between 1/8 DN and 1/2 DN.

n Insert the DWM2000/L until measurement position is reached.

n Take off the housing cover and turn the entire probe so that the arrow

points in flow direction (this system differs from standard DWM

1000/2000).

n Tighten alternatively the two screws (No.3 in sketch) up to max 3N/m,

to seal off the fluid. Complete the installation by tightening screw

(No.2).

Adjustable

Fitting

Welding

Socket

Installation on pipe saddle

Preferred mounting angle: horizontal ±45°

Allen Sealing

Screws (3)

Probe (1)

Adjustable

Fitting (4)

Side Screw (2)

Installation with welding socket

max. pressure 25 bar

B. Installation on Open Channels

n The DWM2000/L can be mounted by using the adjustable fitting.

n Position the device in such a way that the arrow points in the flow

direction.

Remarks

n The electronics block of this long version is interchangeable.

n For safety reasons, keep the security chain mounted, in

order to avoid any ejection in case of overpressure in

the pip e .

n For range settings and electrical connection, refer to DWM2000

standard version instructions.

Installation in an open channel