Electrical connection and settings, Dwm1000 flow switch – KROHNE DWM 1000-2000 EN User Manual

Page 5

5

Electrical Connection and Settings

Electrical Connection

n The wiring terminals for the DWM can be found in the connection chamber (see page 3, item 11).

n The electrical connection conforms to the standard EN61010-1, protection class 1, voltage category II, interference degree 2. n

n The DWM range conforms to EMC directives NF EN 50 081.1 (Emission) and NF EN 50 082.2 (Immunity)

n For DWM

1000 see “ERRATA DWM 1000 Flow Switch”

DWM1000 Flow Switch

n Terminals 1 and 2 are used for the electrical connection (wire

cross-section: max. 1.5mm2 or 16 AWG). Polarity is arbitra-

ry.

n The flow switch must not be connected to power without an

electrical load in series (e.g. relay)!

n The choice for the alarm status NO (circuit open for velocit

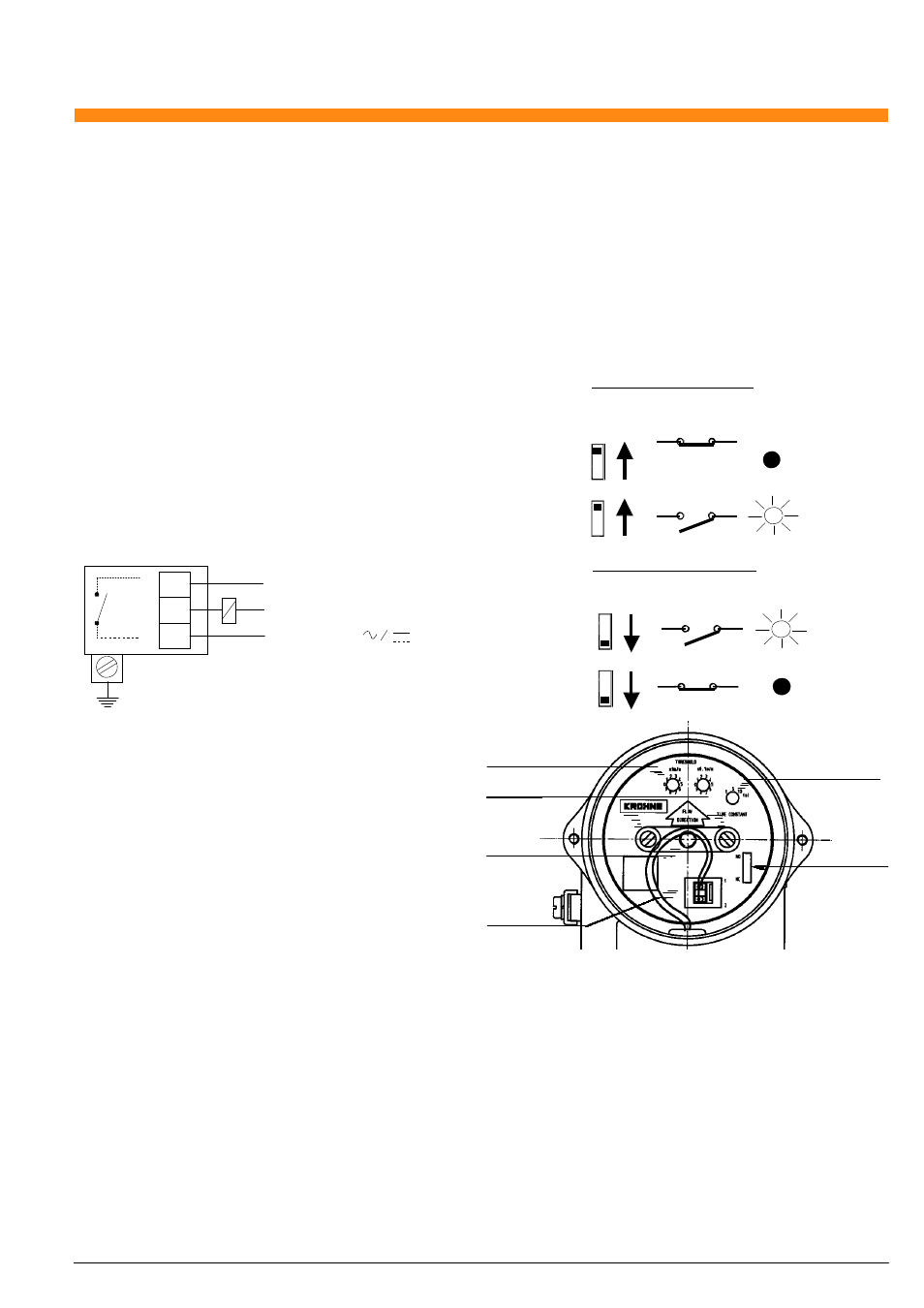

Setting of the Alarm Status

The alarm status can be selected with the invertor (13).

NO - circuit open for velocity higher than reference velocity.

NC - circuit closed for velocity higher than reference velocity.

The LED flashes when the circuit is open.

Make Contact Status (NO)

Internal

higher than reference velocity) or NC (circuit open for inverse

function) can be changed by the switching as detailed on the

right.

n If more than one DWM1000 is used, make sure they are not

connected in parallel. Only one common return is allowed.

Provide a separate fuse for each flow switch.

n Ensure that the earthing of the unit is <10 Ohms.

V V>Vref NO/NC Selector NO Switch LED Off Flashing PE Protective Earth Break Contact Status (NC) Internal LED DWM 1000 1 2 Load e.g. Relay U: 48 - 240 V V NO/NC Selector NC Switch Flashing FE < 10 Ohms (Functional Earth for housing) Relay Limits with compatibility specifications. Refer to the ‘Compatible Relay ’ section for the choice of relay on page 7. Settings V>Vref NC Reference Velocity ref (11) Mounting Screws (14) LED Off Time Constant Dial (12) n Positioning of the electronic block. Open the housing and unscrew the two mounting screws (14) of Setting of the Reference Velocity Setting of the Time Constant (10) Selector NO/NC (13) Power Installation on Piping With Cathodic Protection Removal and Remounting of the Electronic Block

NO

n Always ensure that the voltage and relay voltage correspond

The settings have to be carried out in the following order:

Dials for V

n Setting of reference velocity.

n Setting of the time constant.

n Setting of the alarm status: NO or NC.

the electronic block (only two turns) without taking them out.

Position the block aligning the arrow with the direction of flow in

the pipe (if not aligned false readings will occur). The block is

then fixed by fully tightening the mounting screws.

Set the reference velocity with the two dials (11), one for the

m/s units and the other for the 1/10ths units.

Set the time constant with the dial (12) to 5, 8 or 10 seconds.

Depending on the desired function of the unit, program the time

constant to the largest possible, to avoid unnecessary swit-

ching during fluctuations in the flow rate.

Terminals (9)

Please contact KROHNE directly for instructions.

The electronic block may be removed in security during flow

conditions, as the probe is fully sealed. Before removing the

unit ensure that the power supply is switched off. Unscrew the

two mounting screws fully (14), and pull the block by means of

the plastic bridge.

To replace the block, it should be orientated so that the screws

(14) engage into the threads of the rotating sleeve, and secured

in place with a few turns. Next orientate the block so that the

arrow is in line with the flow direction, and lock the block by fully

tightening the mounting screws.

Note - the replacement block needs to be calibrated.