Installation, Dimensions and weight – KROHNE DWM 1000-2000 EN User Manual

Page 4

4

Installation

Mounting onto the pipeline

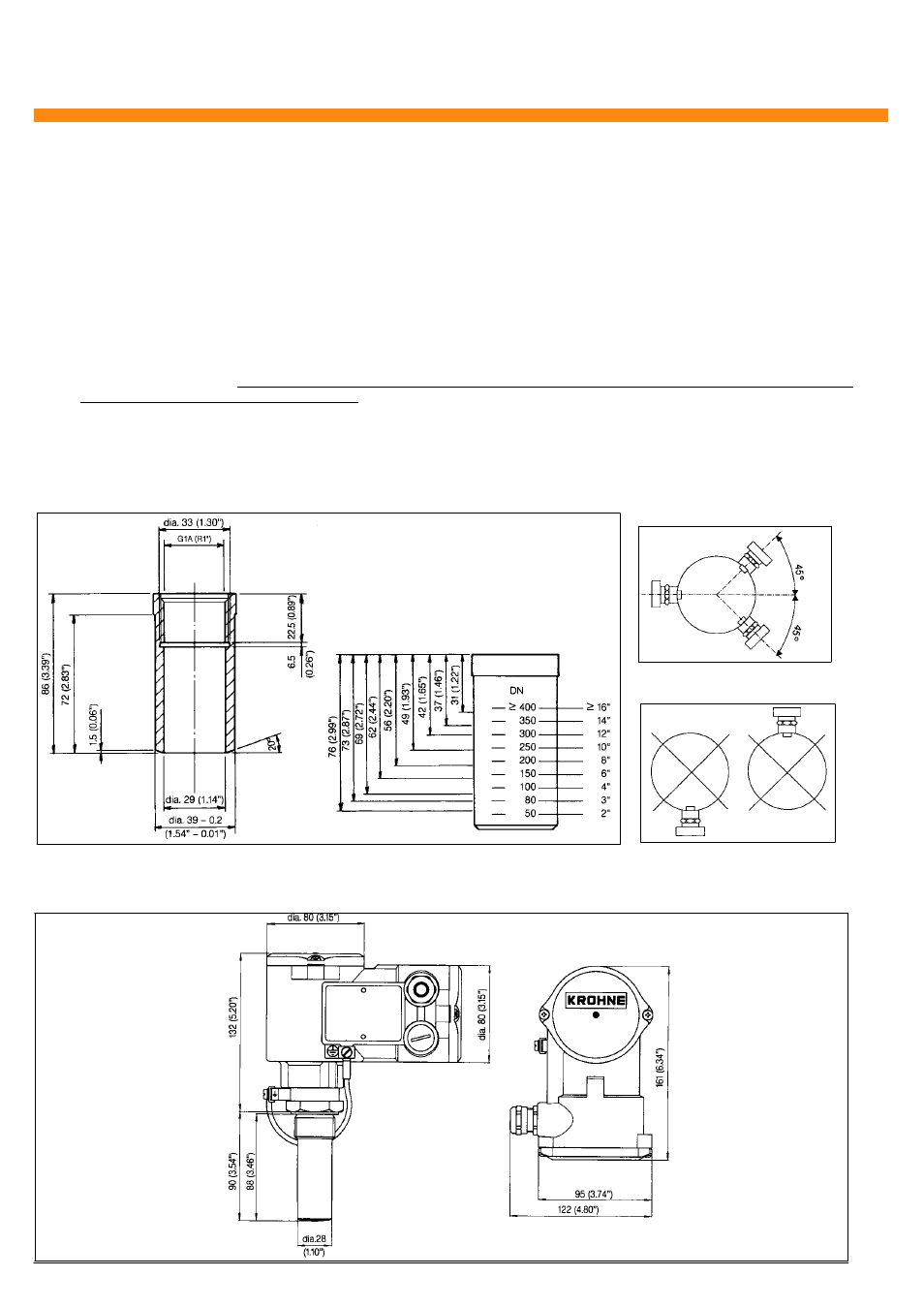

The DWM should be mounted onto the pipeline (nominal diameter (DN) 50mm (2") by means of the connection socket

provided.

Refer to the diagrams below for the orientation and positioning of the connection socket. The socket should be inserted as

far as the corresponding p i p e l i n e diameter (DN) marking. In case there is pipe insulation, it is necessary to calculate the

depth of insertion so that the protrusion of the probe is 1/8 of the true internal diameter (i.e. not the DN).

The location hole in the pipeline should be drilled to a diameter of 39 mm (1.54") with a maximum of 0.5 mm play between

the socket and bore. Secure the socket perpendicular to the pipe with four spot welds, then carry out an unbroken weld of the

entire diameter, with an electrode of 1.2mm diameter and setting of 90 to 150A.

The straight line flow distance required between the DWM and an upstream flow disturbance (inlet, pump, elbow etc) is

advised to be 10 x DN and 5 x DN from downstream disturbances.

The DWM must be installed into the socket using the supplied gasket, which ensures water tightness and flush positioning of

the ceramic probe head. Teflon tape should not be used on the thread as this insulates the required earthing contact, and

prevents from correct protrusion of the probe.

Only the electronics unit must be rotated according to the flow direction (see

“Electrical Connection and Setting”).

Installation on plastic p ipes

In the case where the unit is to be installed on a plastic flow pipe, it is necessary to assure an earth connection. In all cases consult

KROHNE to ensure an effective solution.

Welding

Socket

Correct

Incorrect

Dimensions and Weight

Diecast aluminium housing - weight excluding socket approx. 1.85Kg (4.08lbs)

DWM1000

DWM2000

M20 x 1.5