Electrical connection and settings, Dwm2000 flowmeter (current output) – KROHNE DWM 1000-2000 EN User Manual

Page 6

6

Electrical Connection and Settings

DWM2000 Flowmeter (current output)

The connection and settings have to be carried out in the follo-

wing order:

n Positioning of the electronic block.

n Setting of the full scale.

n Electrical connection and earthing (must be <10 Ohms).

n Zero adjustment.

Positioning of the electronic block

Open the housing and unscrew the two mounting screws (14) of

the electronic block (only two turns) without taking them out.

Position the block aligning the arrow with the direction of flow in

the pipe (if not aligned false readings will occur). The block is

then fixed by fully tightening the mounting screws.

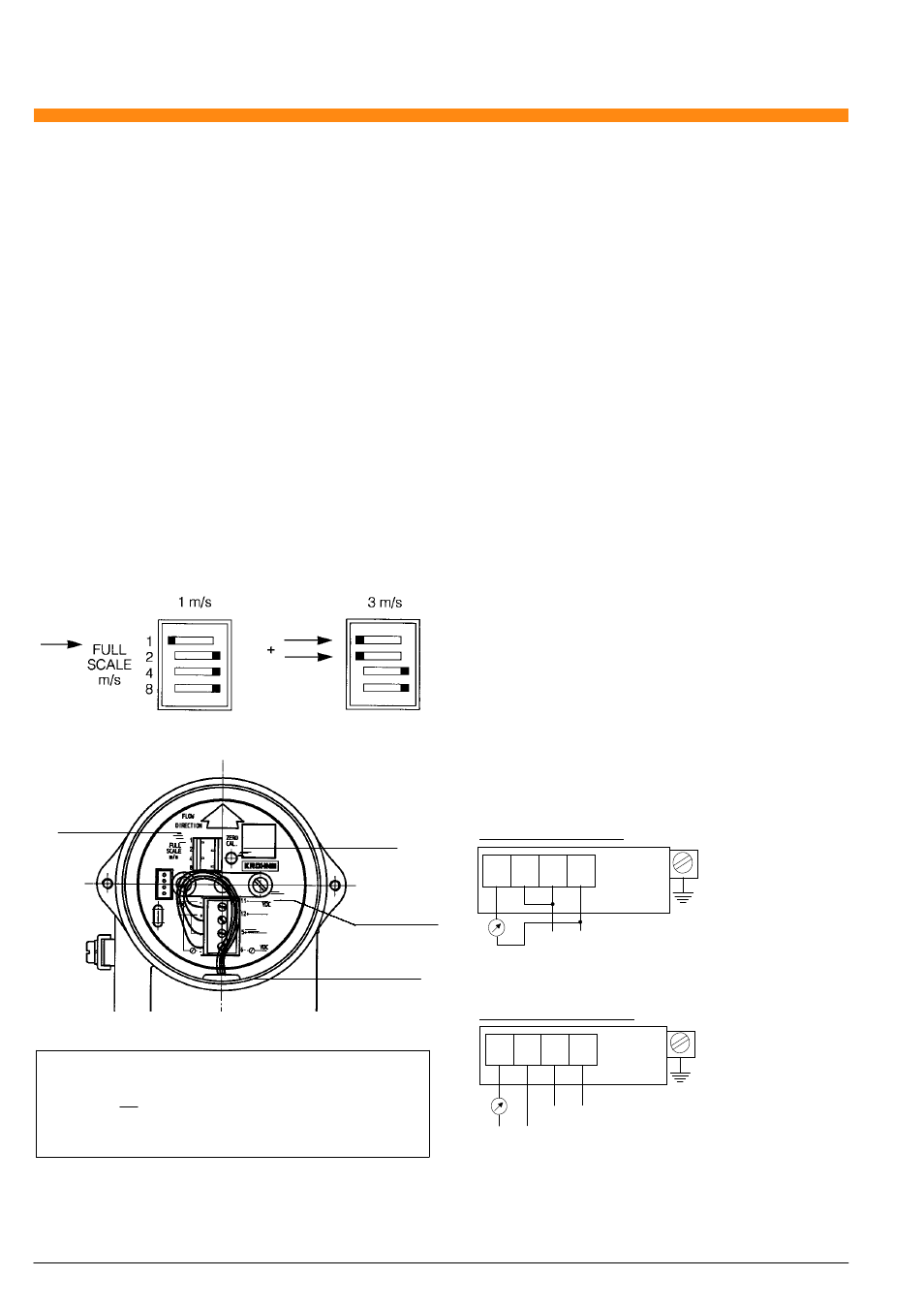

Setting of the Full Scale

The setting of the full scale has to be done before powering up

the DWM2000! Full scale range is from 1 through to 8m/s, and

is set by means of the 1, 2, 4 and 8 value switches. The final

value of the full scale is the sum of the switches activated. The

switch has to be at the side of the inscription to be activated.

If the full scale is set improperly (i.e. >8m/s), the device will be

in alarm status (output current <3mA).

Connection

n Power the unit with 24VDC (power terminals marked 11 (-)

and 12 (+)). Maximum wire diameter is 1.5mm.

n The power consumption at 24VDC is 50mA (max at 20°C)

n Power the current output with 24VDC (power terminals 6 (-)

and 5 (+)). Beware of polarity! Max. load is 500 Ohms.

n One power supply can be used to supply the DWM2000 and

current output (see diagram).

n After powering the DWM2000 will do a self-test (1 minute),

during which current output will be in alarm state (<3mA). If

the self-test is OK the DWM2000 will start measuring, if not,

the output will remain in alarm state (<3mA).

Zero Adjustment

Ensure that the pipe is full. There should be no flow velocity in

the pipe. Press the

“Zero” key. After 1 minute, the zero setting

will be automatically adjusted. During zero calibration, the out-

put indicates alarm status (<3mA).

Piping With Cathodic Protection

Please contact KROHNE directly for instructions.

Removal and Remounting of the Electronic Block

The following procedure must be carried out by a qualified tech-

nician:

The electronic block may be removed in security during flow

conditions, as the probe is fully sealed. Before removing the

unit ensure that the power supply is switched off. Unscrew the

two mounting screws fully (14), and pull the block by means of

the plastic bridge.

To replace the block, it should be orientated so that the screws

(14) engage into the threads of the rotating sleeve, and secured

in place with a few turns. Next orientate the block so that the

arrow is in line with the flow direction, and lock the block by fully

tightening the mounting screws.

Full Scale

Range

Switch

Zero Key

Electrical Wiring

Common Power Supply

6

5

12 11

-

+

+

-

FE < 10 Ohms

Functional Earth

Mounting

Screws (14)

Power

Terminals

+

-

24 V DC

12 V DC (option)

Separate Power Supplies

Reminder for Flow Volume Calculations:

6

5

12 11

-

+

+

-

FE < 10 Ohms

Functional Earth

V = 354

Q

D

2

V = m/s

Q = m

3

/h

+

-

D = internal pipe diameter in mm

24 V DC

-

+

12 V DC (option)

24 V DC

12 V DC (option)

Note: for Zone 2 applications, a fuse is required for the

positive (+) output with a rating

200mA.