Dwm technical data – KROHNE DWM 1000-2000 EN User Manual

Page 11

DWM Technical Data

11

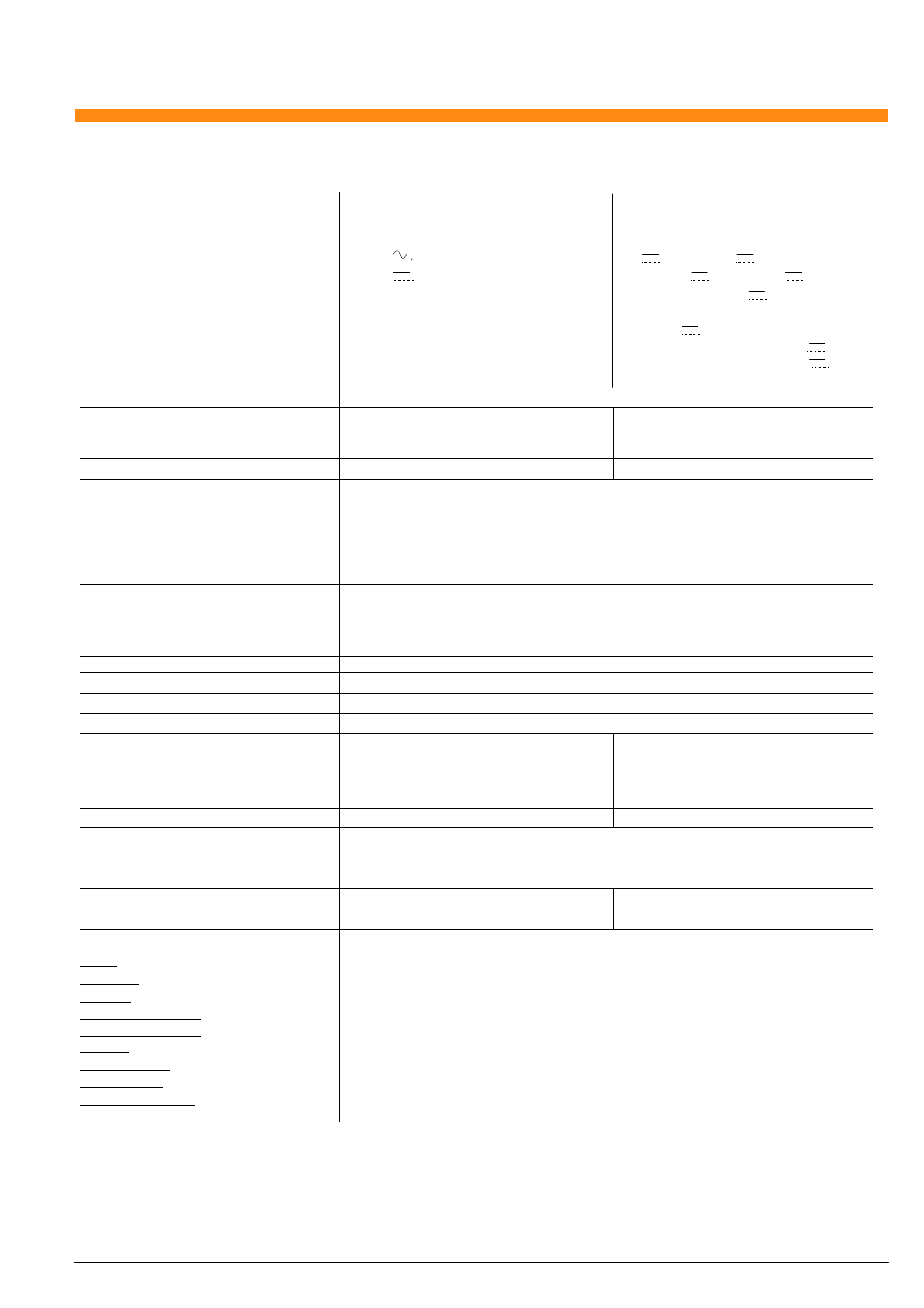

Power Supply and Output

Voltage

Power Consumption

Output

Functional Earth FE (Protective)

DWM 1000 Flow Switch

DWM 2000 Flow Meter

Two Wire System

Output Current 4 - 20 mA

48-240

, 50/60 Hz or

24 (20 to 30 )

48V (Terminals 1/2)

Option: 12 (10 to 14 )

200mA max.

50 mA max. (at 24 and 20°C)

Break or make contact, switch selected

Passive current output 4 - 20 mA

(for relay contact limits see

(20 to 30 )

’Electrical Connection’).

Max. load: 500 Ohms for 24

200 Ohms for 12

<10 Ohms

<10 Ohms

Protective earthing obligatory in connection chamber

Full-Scale Range

“v” Adjustable

Reference velocity between

0.1 and 9.9 m/s (0.3 and 32.5 ft/s)

Full scale 1, 2, 3, 4, 5, 6, 7or 8 m/s

(3.3, 6.6, 9.9, 13.1, 16.4, 19.6, 22.9 or

26.2 ft/s)

Time Constant

choice of 5, 8 or 10 seconds

5 seconds fixed

Operating Data

Liquid

Electrical Conductivity

Operating Pressure

Process Temperature

Ambient Temperature

Largely homogeneous liquids, pastes and slurries, also with solids content

ò20 µs/cm (µmho/cm)

25 bar (360 psi)

- 25 to + 150° C (-13 to +302°F)

- 25 to + 60° C(-13 to +140°F)

Installation

Nominal Pipe Diameter (DN)

Connection Socket

Inlet / Outlet Run

All DNs ò 50 mm

(2”)

Threaded G1A (R

1”)

10 x DN / 5 x DN

Protection Category

IP 55, Equivalent to NEMA 4 IP55 or IP68

Local Display

Flashing LED (DWM 1000 only)

Cable Entry

M20 x 1.5

Power Terminals

Max. wire diameter 1,5 mm

2

(16 AWG)

Error Limits

v > 1 m/s (3.3 ft/s)

v < 1 m/s (3.3 ft/s)

Reproducibility

SP = Switching Point

5% of SP

3 cm/s (1.2 inches/s) + 2% of SP

1% of Switching Point

MV = Measured Value

2% of MV

2 cm/s (0.79 inches/s)

+/- 1.5% of MV

Hysteresis

8% when decreasing velocity

8% when decreasing velocity

Interchangeability

In the case of a breakdown we advise a complete replacement of the DWM unit in

order to preserve the accuracy of the results. A change in the electronic threshold

can induce errors of <10%

Ex Versions Coding (on side label)

Ex n R II T6...T3 X Zone 2

(according to IEC 79-15)

Materials:

Probe

Electrode

Housing

Connection Socket

Cable Entry Gland

Gaskets

Housing Cover

Ceramic Seal

Connection Socket

CrNi - Stainless Steel 1.4435 (SS 316 L - AISI) + ceramic insulation (zirconium oxide)

Platinum

Diecast aluminium with epoxy finish

Stainless Steel 1.4435 (SS 316 L - AISI)

Nickel plated brass

Buna N

Viton

Klingerit (without asbestos)