Technical data, 2 technical data – KROHNE OPTIMASS 7000 EN User Manual

Page 33

TECHNICAL DATA

6

33

OPTIMASS 7000

www.krohne.com

04/2013 - 4001016302 - MA OPTIMASS 7000 R02 en

6.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

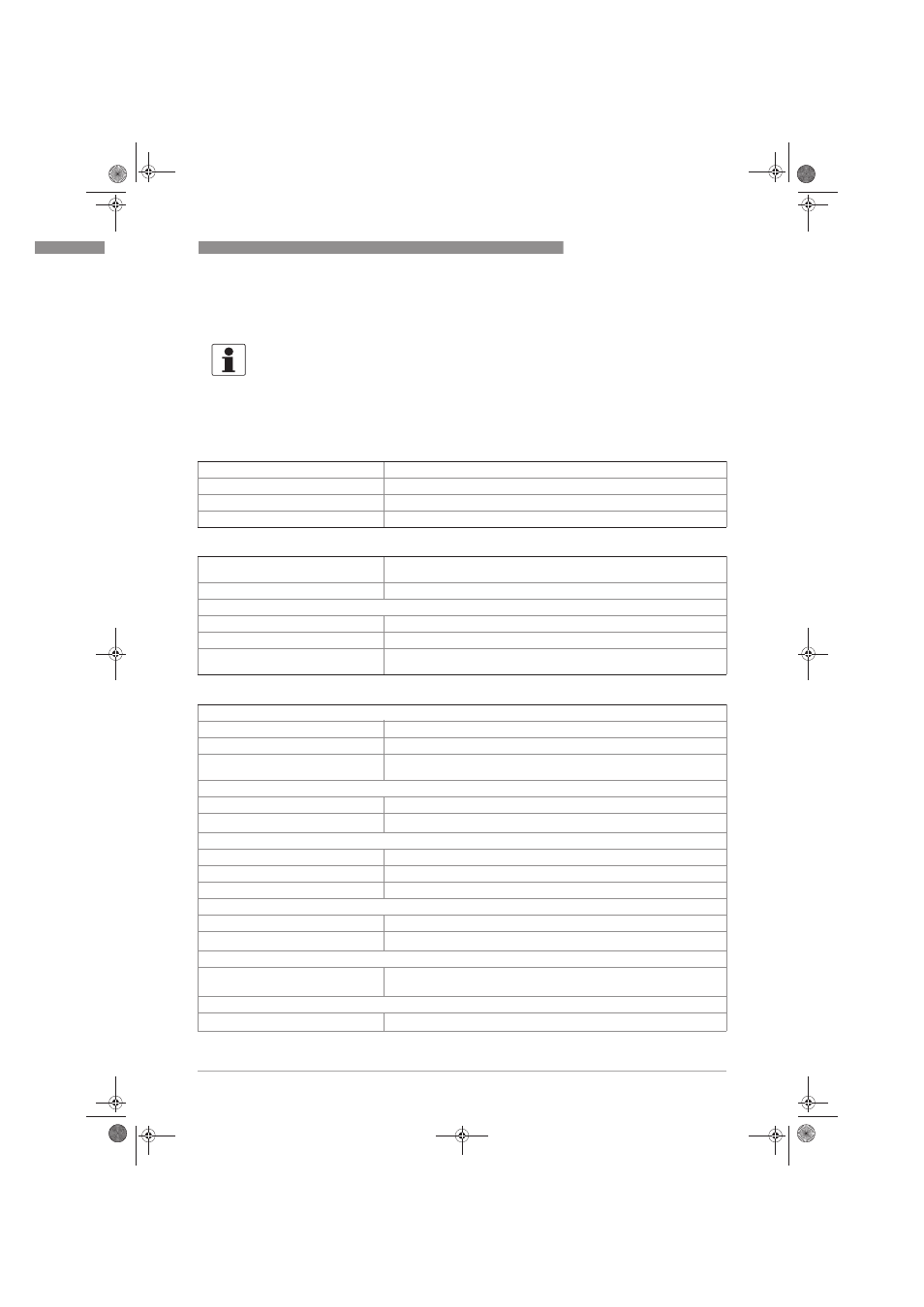

Measuring system

Measuring principle

Coriolis mass flow

Application range

Mass flow and density measurement of fluids, gases and solids

Measured values

Mass, density, temperature

Calculated values

Volume, referred density, concentration, velocity

Design

Basic

System consists of a measuring sensor and a converter to process the

output signal

Features

Fully welded maintenance free sensor with single straight measuring tube

Variants

Variants

Variants

Variants

Compact version

Integral converter

Remote version

Available with field, wall or 19" rack mount versions of the converter

Modbus version

Sensor with integral electronics providing Modbus output for connection to a

PLC

Measuring accuracy

Mass

Mass

Mass

Mass

Liquid

±

0.1% of actual measured flow rate + zero stability

Gas

±

0.35% of actual measured flow rate + zero stability

Repeatability

Better than 0.05% plus zero stability (includes the combined effects of

repeatability, linearity and hysteresis)

Zero stability

Zero stability

Zero stability

Zero stability

Titanium

±

0.004% of maximum flow rate with respective sensor size

Stainless Steel / Hastelloy

®

/ Tantalum

±

0.015% of maximum flow rate with respective sensor size

Reference conditions

Reference conditions

Reference conditions

Reference conditions

Product

Water

Temperature

+20°C / +68°F

Operating pressure

1 barg / 14.5 psig

Effect on sensor zero point caused by a shift in process temperature

Effect on sensor zero point caused by a shift in process temperature

Effect on sensor zero point caused by a shift in process temperature

Effect on sensor zero point caused by a shift in process temperature

Titanium

0.001% per 1°C / 0.00055% per 1°F

Stainless Steel / Hastelloy

®

/ Tantalum

0.004% per 1°C / 0.0022% per 1°F

Effect on sensor zero point caused by a shift in process pressure

Effect on sensor zero point caused by a shift in process pressure

Effect on sensor zero point caused by a shift in process pressure

Effect on sensor zero point caused by a shift in process pressure

Titanium / Stainless Steel / Hastelloy

®

/

Tantalum

0.0011% of the max flow rate per 1 bar

rel

. / 0.000076% per 1 psig

Density

Density

Density

Density

Measuring range

400...2500 kg/m

3

/ 25...155 lbs/ft

3

MA_OPTIMASS_7000_en_042513_4001016302_R02.book Page 33 Tuesday, July 2, 2013 5:23 PM