3 calibration log, 4 troubleshooting, Operation – KROHNE OPTISENS PH 9500 User Manual

Page 36

4

OPERATION

36

OPTISENS PH 9500

www.krohne.com

08/2012 - 4001929601 MA OPTISENS PH 9500 R01 en

4.3.3 Calibration log

Accessing the calibtration log

• You are on the data level and you see the calibration history. With the help of or you can

scroll through the different entries.

• If you want to return to the measuring mode press ^ several times until you reach this mode.

4.4 Troubleshooting

INFORMATION!

In order to show the history of the calibrations, the signal converter has a calibration logbook

function. Up to 64 entries of the calibration history are stored including date and time.

•

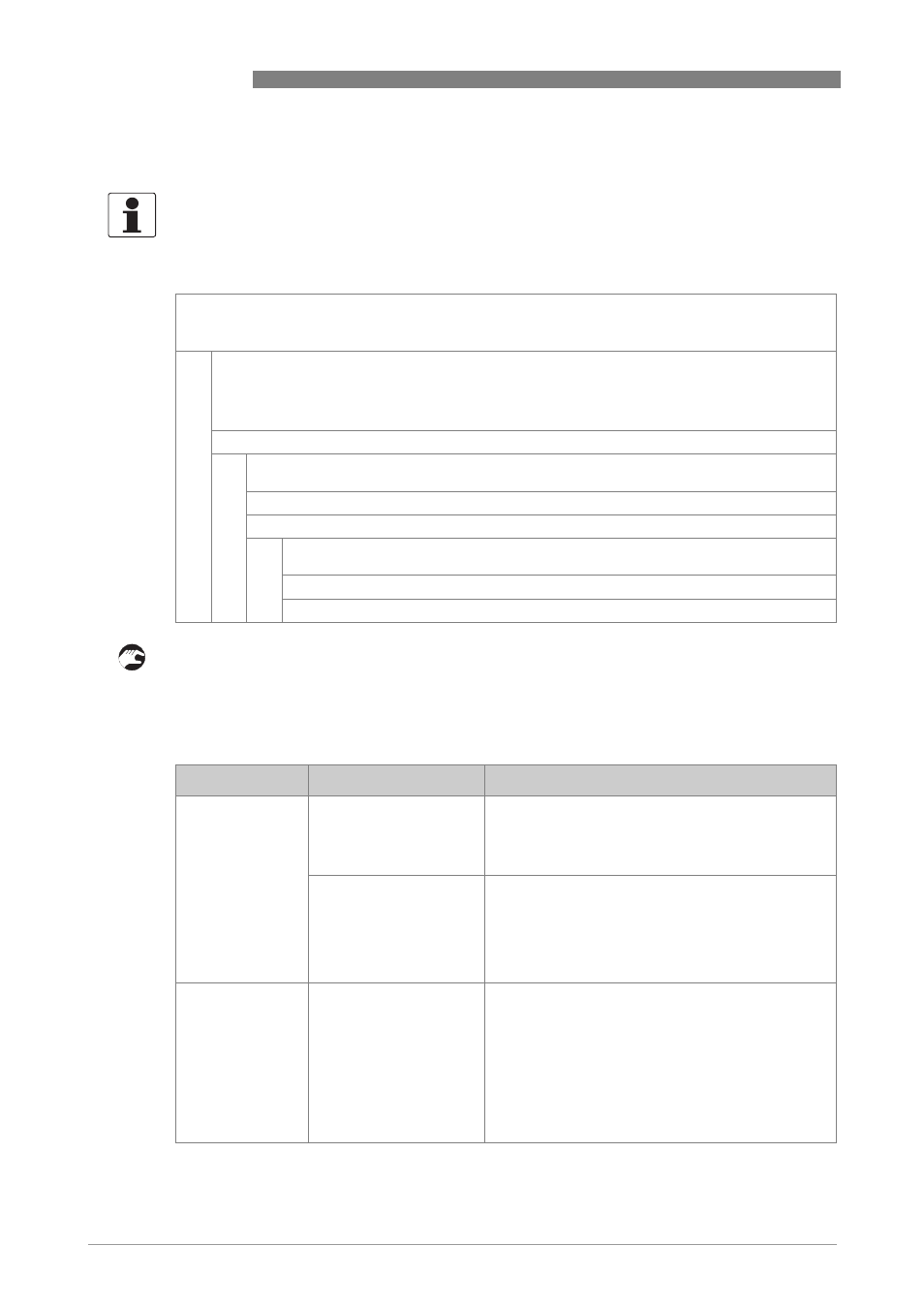

Press > for more than 2.5 seconds, then release the button. You are on the main menu level. In the

upper line of the display "A" appears, beneath the main menu quick setup is highlighted.

•

Press or until the main menu test is highlighted.

MAIN MENU

A quick setup

> B test

C setup

D service

Press > to enter the chosen menu.

You are on the first submenu level. In the upper line of the display "test" and "B1" appears,

beneath the submenu sim.process input A is highlighted.

Press or until the submenu logbooks is highlighted.

Press > to enter the chosen menu.

You are on the second submenu level. In the upper line of the display "logbooks" and

"B1" appears, beneath the submenu status log is highlighted.

Press or until the submenu calibration log is highlighted.

Press > to enter the chosen menu.

Problem

Possible cause

Remedy

The pH sensor

does not deliver a

signal.

Mechanical damage of the

glass bulb, e.g. small

cracks. This will shortcut

the ion exchange and

deliver a pH7 reading.

Exchange sensor.

Moisture inside the

sensor connector. This

will shortcut the signal

between pH glass half cell

and reference half cell

and deliver a reading of

pH7.

Clean the connector (sensor/cable) with pure water

and dry with air (e.g. hair blower).

The pH sensor

delivers an

unstable signal.

The diaphragm in the

reference half cell does

not provide good contact

to the process medium

due to drying up or

coatings.

•

Clean the diaphragm with hot soap or acid using a

soft tissue (details on page 37).

•

Submerge sensor in water and increase the

temperature to 50...60°C / 122...140°F.

•

Submerge sensor in 3 molar KCl solution at ambient

temperature. The decrease in temperature will cause

the reference half cell to suck in KCl solution through

the diaphragm and regenerate the diaphragms

functionality.