6menu settings for profibus-pa, 4 profibus-pa connection, 1 parameter “meter_type” of ufc030 – KROHNE UFC 030 PROFIBUS PA User Manual

Page 9

Supplementary documentation UFC030 with PROFIBUS-PA

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5

D-47058 Duisburg

9/17

Tel.: 0203-301 309

Fax: 0203-301389 · e-mail: [email protected]

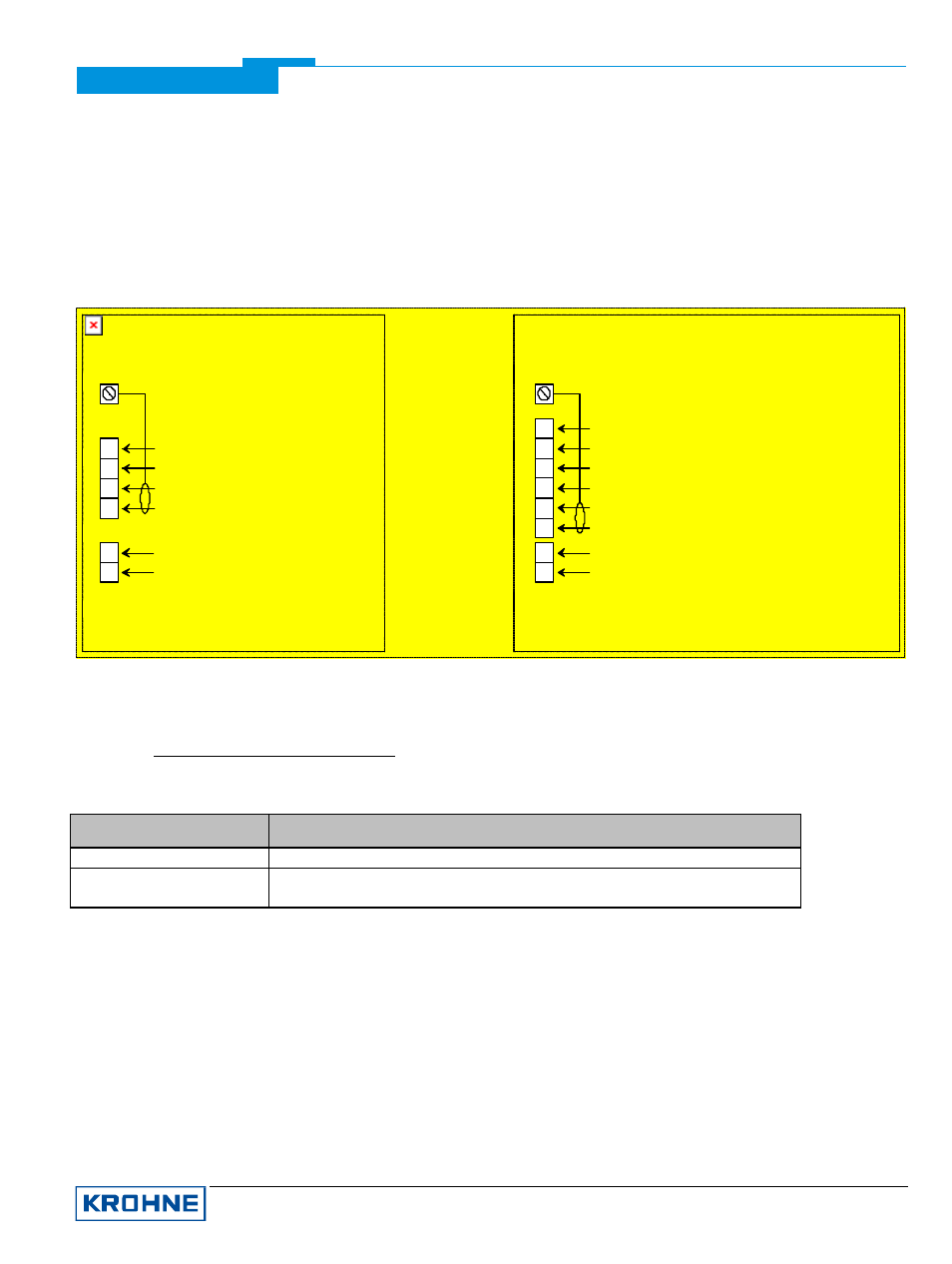

5.4 PROFIBUS-PA connection

Connect the bus cable as shown in the figure.

•

Connect the cable cores to the terminals

described as PA+ and PA-.

•

Polarity reversal will not have any effect.

•

The cable shield should be connected with

minimum length to the PE functional ground.

•

The equipotential bonding conductor must be

connected to the device by connecting it to PE

functional ground

N

L

D -

D +

I-

I+

Device Model:

EX-modis Version 1 / 2

N

L

l / C / P

Device Model:

Aqua-sonic 2

PE

PE

}

}

}

PROFIBUS-PA Interface

Puls- / Current-Outp. / Digital Inp.

(optional, no communication)

UFC5000 Power Supply

}

}

}

PROFIBUS-PA Interface

Current / Puls Output

(optional, no communication)

UFC5000 Power Supply

A2

A1

GND

}

}

}

Analog Input 1

Analog Input 2

Circuit Ground

D -

D +

6

Menu Settings for PROFIBUS-PA

For a detailed description please check the Installation and Operating Instructions manual of the device. The

following settings should be done before the UFC030 (UFC 3 Beam) will be connected with the PROFIBUS-

PA network. Note that the address can be also set by using the communication service “Set slave address”

via the master tool.

Function (Fct.)

Description

3.9.1

PROTOCOL

•

PROFIB PA

3.9.3 PR/FF ADDR

•

Set address

Range: 000 - 126 for PROFIBUS-PA (default 126)

The PROFIBUS address can be changed via the PROFIBUS service “Set_Slave_Address”. The input range is

0...125 according to the PROFIBUS specification. Address 126 is the default address and cannot be set via the

PROFIBUS -PA service “set_slave_add”.

7

Important Notes

7.1 Parameter “meter_type” of UFC030

If “meter_type” will be changed by a service technician the below mentioned procedure must be carried out

step by step to avoid UFC030 malfunctions depending on an inconsistent data set of the PROFIBUS -PA

module.