KROHNE UFC 030 PROFIBUS PA User Manual

Page 5

Supplementary documentation UFC030 with PROFIBUS-PA

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5

D-47058 Duisburg

5/17

Tel.: 0203-301 309

Fax: 0203-301389 · e-mail: [email protected]

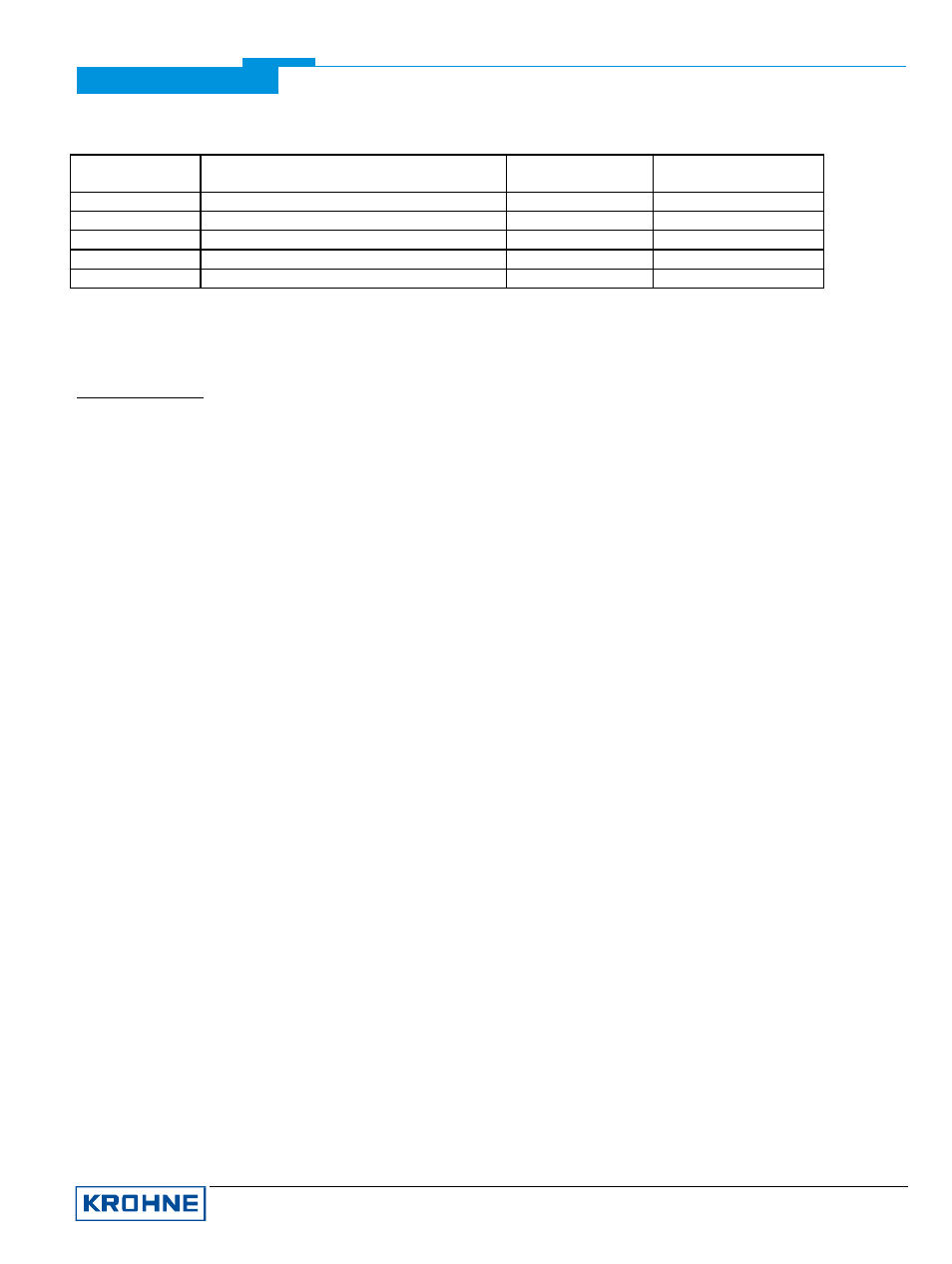

KROHNE delivers the GSD files with the entire device functionality, which is listed below:

Block Number

Standard-Configuration

(function block output value)

KROHF701.GSD

Ident-No. F701

1

Volume Flow

AI-FB

2

Speed of Sound

AI-FB

3

Volume Totalizer

Totalizer-FB

4

CORR. Volume Flow or HEAT Flow *

AI-FB

5

CORR. Volume- or HEAT- Totalizer *

Totalizer-FB

AI

= Analog Input Function Block

FB

= Function Block

•

= depends on the current device type selection

Important Notes:

1.

To project the PROFIBUS communication network you have to allocate each block to a function. On the PC-S7

from Siemens this will be done with the Tool named “HW- Config”. This tool offers the functions described as

follows:

2.

It is possible to program an “Empty” block (the code of an “Empty” block is defined as 0x00) on each block

number. This means, that for this block no data are transmitted in the cyclic data telegram.

3.

There is NO “Totalizer (TOT)” function block allowed on block position 1, 2 and 4! A “Analog Input (AI)” function

block or a “Empty” block is allowed here only! That means a “Totalizer (TOT)” function block is not possible at

this positions.

Note: All codes of “Analog Input (AI)” - and “Totalizer (TOT)” – function blocks valid for use will be find in the

corresponding GSD files.

4.

There is NO “Analog Input (AI)” function block allowed on block position 3 and 5! A “Totalizer (TOT)” function

block or a “Empty” block is allowed here only! That means a “Analog Input (AI)” function block is not possible at

this positions.

5.

There is a choice of 4 different totalizer functions, which can be allocated to the blocks 3 and / or 5. The 4

functions are defined as follows:

Function “Totalizer”

cyclic transfer of the totalizer

with status to the master

Function “SetTot_Total”

cyclic transfer of the totalizer

with status to the master + cyclic control data

from master to the device via the Bytes SetTot

Function “ModeTot_Total”

cyclic transfer of the totalizer

with status to the master + cyclic control data

from master to the device via the Bytes ModeTot

Function “SetTot_ModeTot_Total” cyclic transfer of the totalizer

with status to the master + cyclic control data

from master to the device via the Bytes SetTot and after that ModeTot

Both, the Byte SetTot and ModeTot are being sent cyclical from the Master to the device if these bytes are

inserted as output data via the to the PLC configurator. The meaning of these control bytes are as follows:

SetTot:

SetTot =0:

Totalizer is totalizing.

SetTot =1:

Totalizer will be reset to 0 and stays at 0 until SetTot is switched back again to 0. If the value of

SetTot changes from “1” to “0” the totalizer starts counting from 0.

SetTot =2:

Totalizer is set to the value defined by PresetTot. PresetTot can be written via a acyclic master

(totalizer in block 3 = Slot 3 Index 32; totalizer in block 5 = Slot 5 Index 32).If the value of SetTot

changes from “1” to “0” the totalizer starts counting from the current value defined by PresetTot.

SetTot

>

2:

not allowed

ModeTot:

ModeTot = 0 totalizer totalizes positive and negative values.