1general, 2items included with supply, 3software history – KROHNE UFC 030 PROFIBUS PA User Manual

Page 3: 4profibus-pa, Issued

Supplementary documentation UFC030 with PROFIBUS-PA

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5

D-47058 Duisburg

3/17

Tel.: 0203-301 309

Fax: 0203-301389 · e-mail: [email protected]

Control system (PLC)

Class 1 master

Segment

coupler /link

Analog I/O module

PROFIBUS-PA

4-20 mA

HART device

Power

Supply

PROFIBUS-PA

Segment

coupler/link

PROFIBUS-DP, up to 12 Mbit/s

Engineering or operation

control tool

Class 2 master

K

R

O

H

N

E

1 2 3 4 5 6

K R O H N E

1 2 3 4 5 6

1 0 0 0

9 0 0

8

0

0

700

6 0 0

5 0 0

4 0 0

300

2 0 0

kg/h

100R P

K R O H N E

H250

S

N

586 677/01-03

M

C

H250/RR/M9/K2/ESK-Z

C

K25.2 1.4571

F

CIV 25 1.4571

M

D

1 9 9 7

C2H50H

D

0 . 9 3 k g / l

V

2.5 mPa.s

T

2 3 . 5 C

P

0 . 4 M P a

FIA 1025

k

g

0

3

6

8

7

2

1

General

These Instructions are supplementary to the ”Installation and Operating Instructions (Reference Manual) UFC030

(UFC 3 Beam)”. The details given there, in particular the Safety Information, are valid and should be observed. These

Supplementary Instructions provide only additional information for device operation and connection to a PROFIBUS-

PA fieldbus.

2

Items included with supply

In addition to the standard scope of supply, these Supplementary Instructions for the UFC030 with PROFIBUS-PA

interface plus a diskette containing all PROFIBUS device data files (GSD files) available of all KROHNE devices will

be included.

3

Software history

Issued

Signal converter

User program

Instructions

month/year

Hardware

Firmware

Hardware

Operating

system

Software

Device

User program

10/03

PROFIBUS-PA

Module+Device

MOD3 /031010 PC

Windows 95,

98, NT 4.0,

ME, 2000

PDM

≥

V 5.2

--

--

4

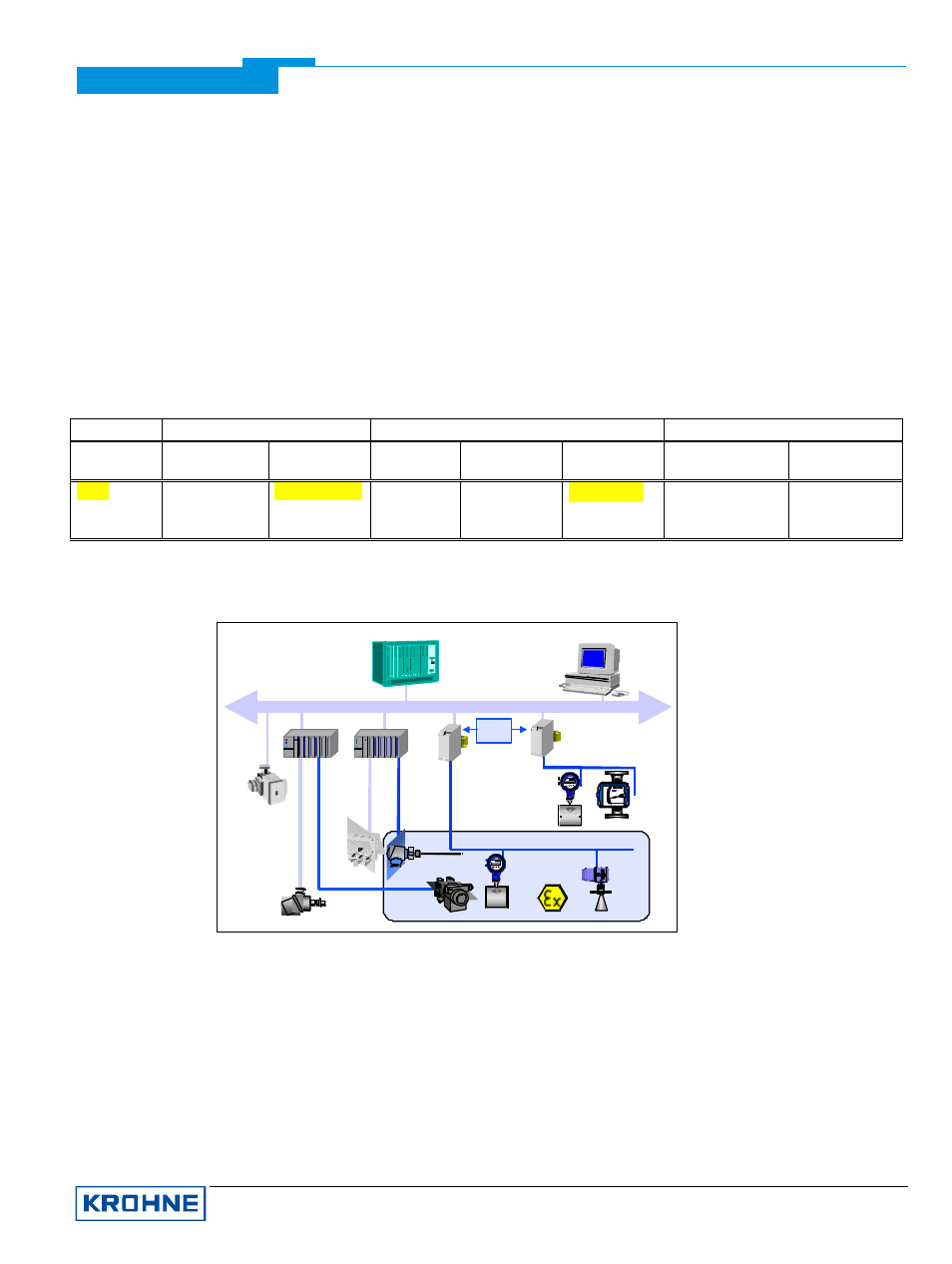

PROFIBUS-PA

The diagram above shows a typical instrumentation with PROFIBUS-PA devices in hazardous and non-hazardous

locations, including connections of conventional devices (e.g. with 4-20mA signals) to the PROFIBUS-PA.

The PROFIBUS-PA is normally connected to a segment coupler which, among other things, carries out the

conversion to the PROFIBUS-DP. Here, it needs to be noted in particular that the segment coupler is normally set to

a fixed baud rate on the DP side.

Further information on the planning and operation of PROFIBUS-PA networks is to be found in the KROHNE

brochure ”PROFIBUS-PA Networks”.