8technical data – KROHNE UFC 030 PROFIBUS PA User Manual

Page 10

Supplementary documentation UFC030 with PROFIBUS-PA

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5

D-47058 Duisburg

10/17

Tel.: 0203-301 309

Fax: 0203-301389 · e-mail: [email protected]

1.

UFC030 (Converter) data set must be reset to factory values first (Menu: 5.1.1 -> FACT PARAM)

2.

“meter_type” must be changed into the device type required

3.

UFC030 (Converter) data set must be saved again as factory values

4.

A factory reset (factory reset = 1 / cold start) must be carried out via PDM (or any other PROFIBUS-PA

Master Tool available) to guarantee a consistent data set of both units (UFC030 converter and

UFC030 PROFIBUS -PA module)

8

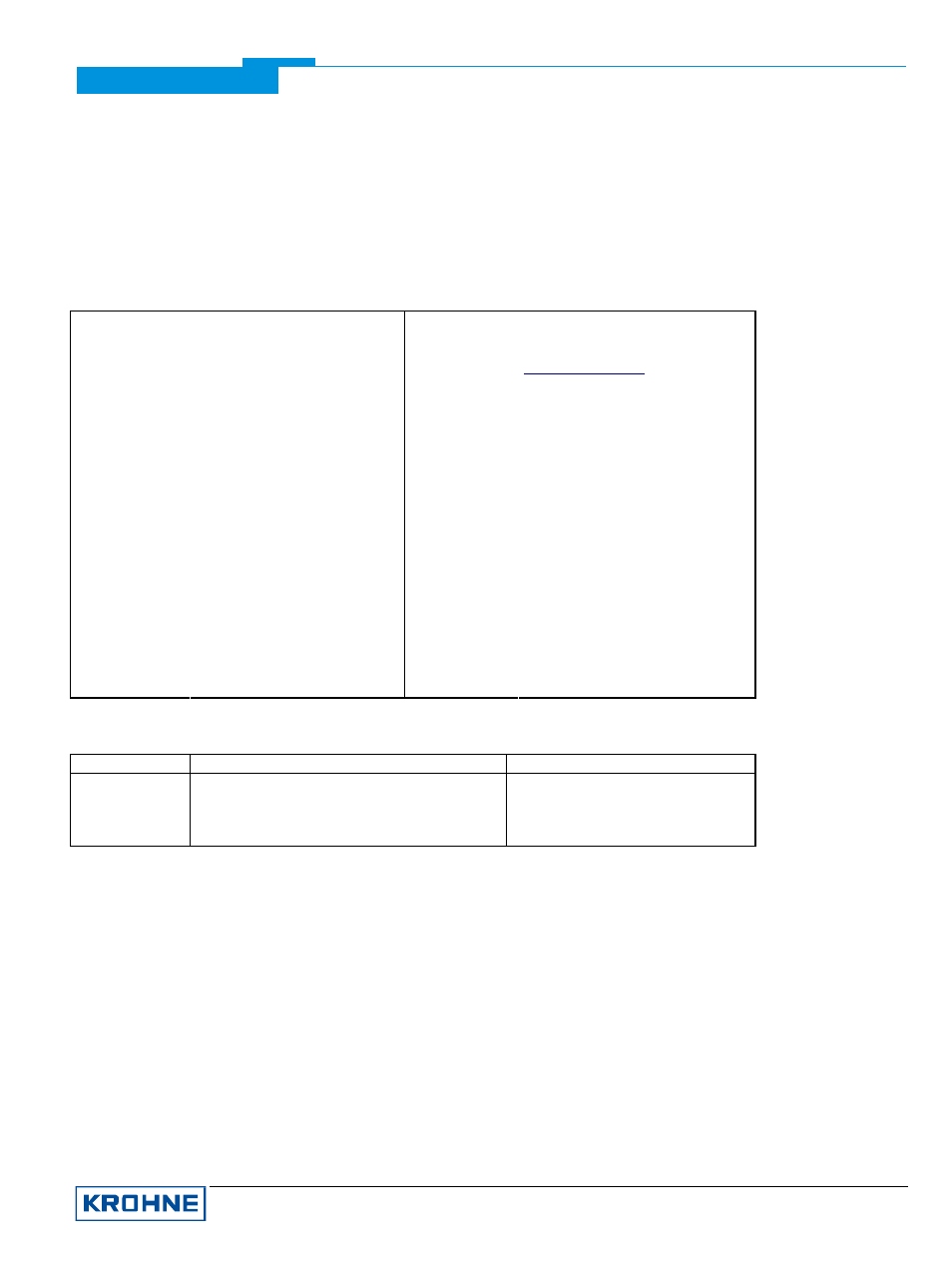

Technical Data

Hardware

Software

Physical

IEC 61158-2; 31,25kbit/s;

voltage mode

GSD

GSD file supplied on diskette or at

http://www.krohne.de

Connection

independent of polarity

Device profile

Profile compact class B, V3.0

Base current

10,5 mA

Address range

0...126; default 126

0 to 125 via “set_slave_add”

0 to 126 via “Local Display”

(Fct. 3.9.1 & 3.9.3)

FDE

yes: separate fault

disconnection electronics

provided

Operator control

local display and operator interface at

device.

Fault current

6 mA; (fault current = max.

continuous current – base current).

SAP’s

3; the number of Service Access Points

is typically equal of the maximum

number of master class 2 (operating)

tools

Starting current

lower than the base current

“Ex“ approval

EEx ia IIC T6 or EEx ib IIC/IIB T6,

details see manual

Function Blocks

1 PB

1 TB

3 AI

2 TOT

Possible function block outputs [default unit]:

Analog Input

Totalizer

default

configuration

FB1: volume flow [m3/h]

FB2: speed of sound [m/s]

FB4: corr. volume flow [m3/h] or heat flow [MJ/s]*

FB3: volume totalizer [m3]

FB5: corr. volume totalizer [m3] or

heat totalizer [MJ]*

* depends on current device type