KROHNE CORIMASS MFC 85 EN User Manual

Page 12

12

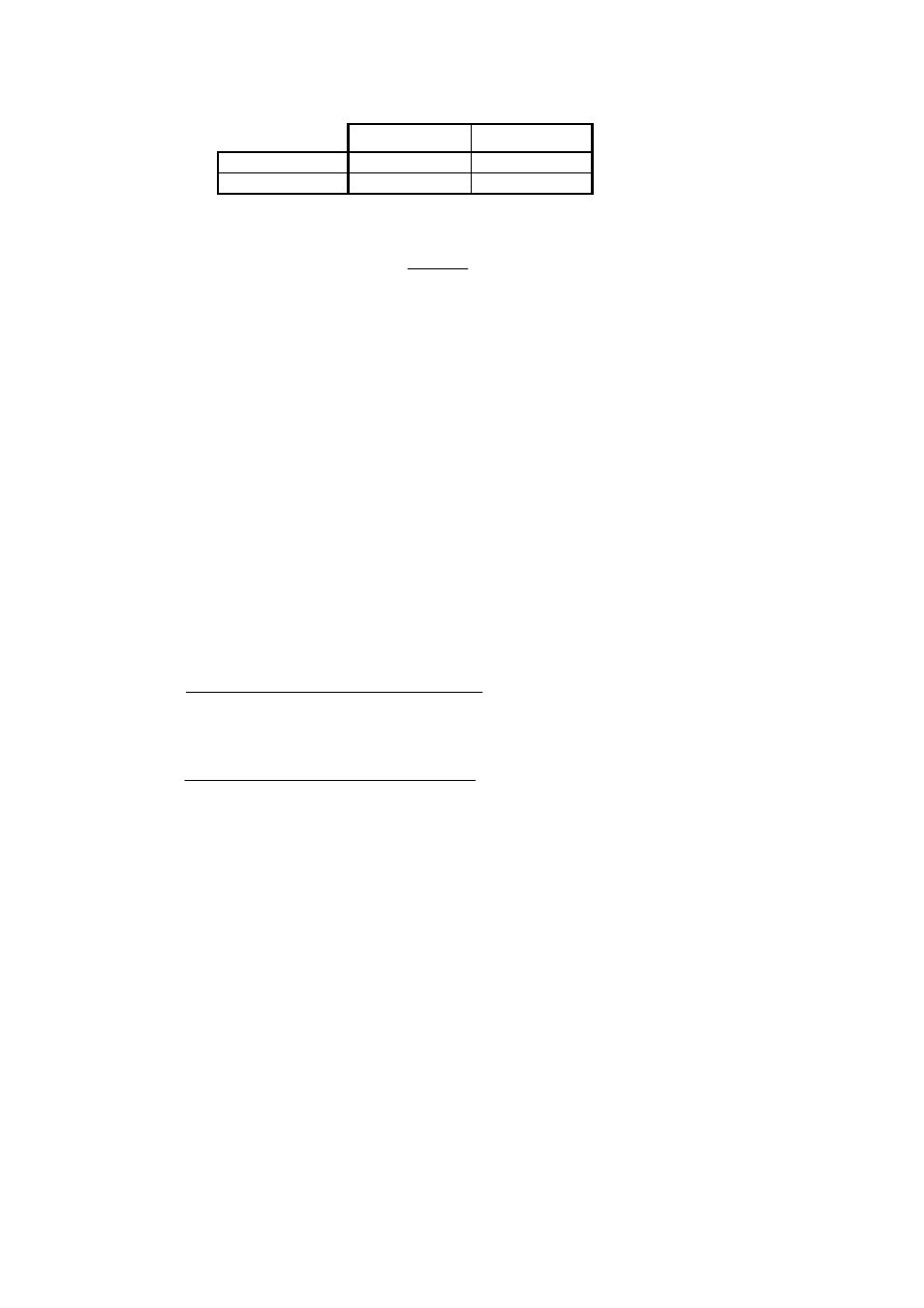

Temperature °C

Density

1st Point

T

1

ρ

1

2nd Point

T

2

ρ

2

Set: Fct. 3.10.4 LIQUID

=

NON WATER

Fct. 3.10.7 LIQUID K2

=

0

Fct. 3.10.6 LIQUID K1

=

ρ

ρ

1

2

1

2

−

−

T

T

Fct. 3.10.5 LIQUID R20

=

(

)

ρ

1

1

1

20

−

−

K T

To fully fit the temperature compensation equation to the real fluid three different temperature /

density points are required; (

ρ

1

,T

1

), (

ρ

2

,T

2

), and (

ρ

3

,T

3

). This gives a set of three equations

with three unknowns to be solved simultaneously.

(

)

(

)

(

)

(

)

(

)

(

)

ρ

ρ

ρ

ρ

ρ

ρ

1

20

1

1

2

1

2

2

20

1

2

2

2

2

3

20

1

3

2

3

2

20

20

20

20

20

20

=

+

−

+

−

=

+

−

+

−

=

+

−

+

−

K T

K T

K T

K T

K T

K T

Manual solution of these equations is possible, especially if one of the temperatures T

1

,T

2

or

T

3

= 20°C. However this is tedious and mistakes are easily made. It is recommended that the

Microsoft Excel

spread sheet file CONC4.XLT should be used to solve these equations

automatically.

Should a PC running Microsoft Excel

version 5 or later not be available the solution of these

equations is as follows:

(

)

(

)

(

)

(

)

(

)

(

)

K

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

K

K T

K T

T

T

K T

K T

2

1

3

2

2

1

3

3

2

1

3

2

2

1

2

2

1

3

1

2

3

2

1

1

2

2

1

2

2

2

2

1

2

20

1

1

1

2

1

2

20

20

20

20

=

−

+

−

+

−

−

+

−

+

−

=

−

−

−

+

−

−

=

−

−

−

−

ρ

ρ

ρ

ρ

ρ

ρ

ρ

(

)

(

)

(

)

(

)

Case 3:

Oil Water Emulsions

For this case the oil should be treated as the “solid” component, and the LIQUID (Fct. 3.10.4)

should be set to WATER. The calculation of the oil’s density parameters (Fct. 3.10.1 - 3) are

calculated in the same way as described for the liquid carrier in Case 2 above.