KROHNE CORIMASS MFC 85 EN User Manual

Page 11

11

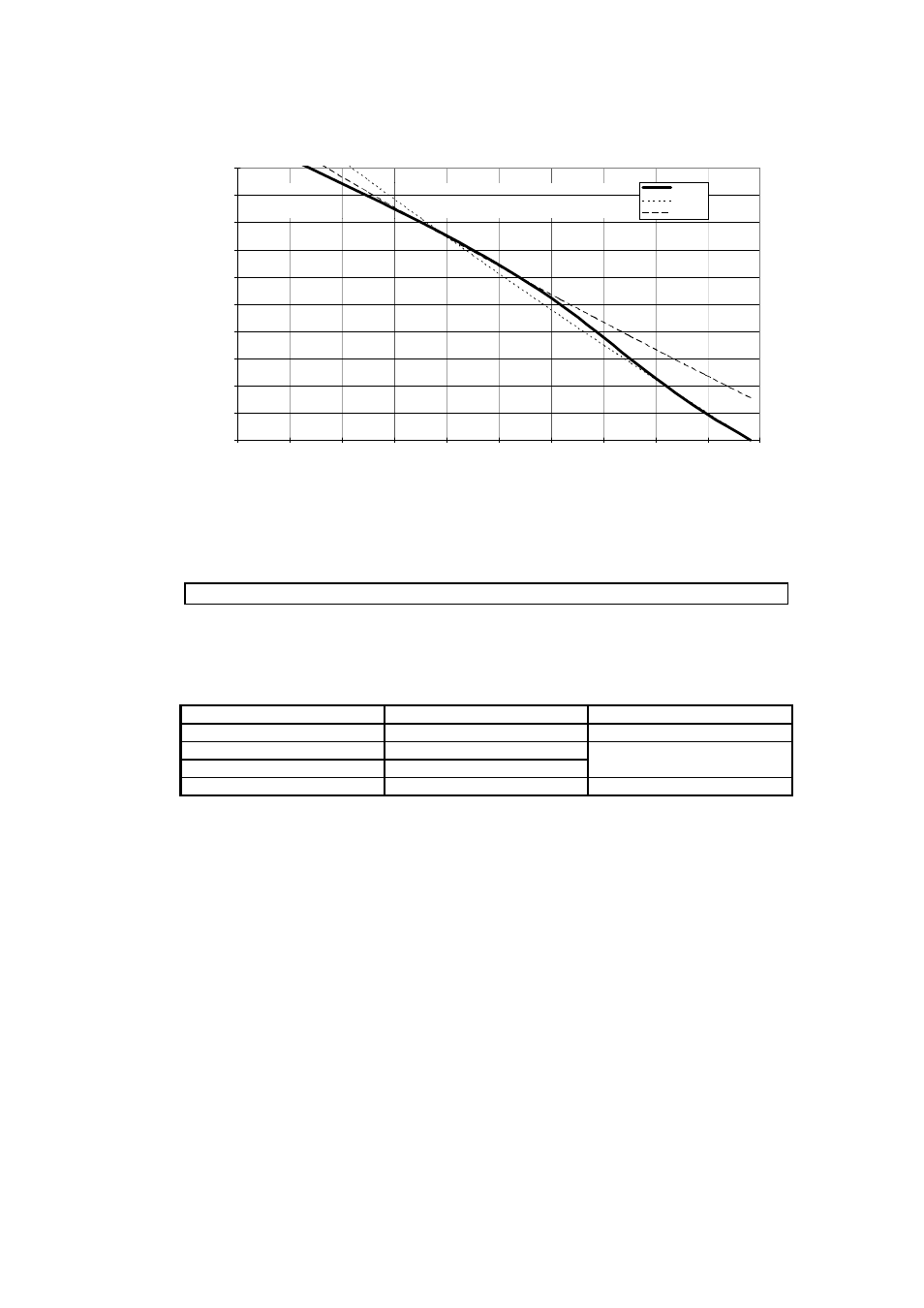

C onc e ntratio n o f E th ano l in W a te r at 2 0 °C

0

5

10

15

20

25

30

35

40

45

50

0.9

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

1

D ensity g /cc

Conc. by Mass

E thanol

F it 1

F it 2

As can be seen Fit 1 matches the characteristic from about 0 to 12% ethanol, whereas Fit 2

matches the range 28 to 43%. Note, for these cases, although the liquid carrier is water it is

necessary to set the Liquid type (Fct. 3.10.4) to NON WATER so that the curves can be

adjusted for best fit.

4.3

Determining the General Concentration Parameters

Case 1:

Solid suspensions in water.

For these cases the solid particles tend to have a density much greater than that of water and

their density can usually be considered not to vary significantly with temperature. Therefore

set:

Menu

Setting

Comments

Fct. 3.10.1 SOLUTE R20

Density of the dry solid

Fct. 3.10.2 SOLUTE K1

0

No temperature correction

Fct. 3.10.3 SOLUTE K2

0

necessary

Fct. 3.10.4 LIQUID

WATER

This is the simplest case. There are some exceptions where the density of the dry solid differs

greatly from its apparent density when wet. Starch is one such substance, in this case the

starch will actually absorb water when wet.

Case 2:

Solid suspensions in other liquids

As for Case 1 the dry solid density can be input in the same manner. However the converter

needs to know how the liquid carrier’s density varies with temperature. If the process always

operates at the same temperature it is acceptable to input the carrier’s density at that

temperature into Fct. 3.10.5 LIQUID R20, and to set Fct. 3.10.6 and 3.10.7 to zero. However

errors will result if the process is then operated at a different temperature.

If the density of the carrier is known only at two different temperatures then only a linear

compensation is possible.