KROHNE DA Flap-type EN User Manual

Page 6

2

Installation and Start-up

2.1

Prerequisite for the installation

The operating pressure of the plant may not exceed the value indicated on the rating plate.

Ensure that the parts coming into contact with the medium are compatible with the material.

The ambient and medium temperatures may not exceed certain maximum values.

In order to prevent distortions the connecting flanges have to face each other axially and in parallel.

2.3

Preparation of the pipeline

Generally comply with the maximum pressure and maximum temperature levels allowable

for the SDA at the measuring point in your plant. The direction of flow must be the same as that

indicated by the flow arrow on the device.

Drain the pipelines before installing the device.

Use gaskets made of rubber or SIL; for plastics devices, use only gaskets made of rubber with

a Shore hardness A of approx. 65°.

The gaskets should not project into the pipeline and the flow meter must be in line with the pipe

axis, otherwise measurements would be falsified and/or the device could jam.

Incorporating the indicator part in the equipotential bonding system in the hazardous area:

The indicator part must be earthed. This can be done e.g. using a wire jumper between the

flange on the indicator part and a pipe flange on the main pipeline with cable lugs appropriate

for the bolted connection (not included with the flow meter!).

Incorporating the indicator in the lightning protection system (if necessary). The Operator is

responsible for checking and determining the scope!

2.4

Observance of the IP degree (NEMA Type) of protection

The following instructions are to be observed in order to observe the IP degree (Nema Type) of electrical built-

in parts:

● After the connecting cable has been introduced, tighten the outlet nut.

● All the cable glands which are not used remain closed with blanking plugs.

● Do not kink lines directly at the cable gland.

● Provide a drain bend

● The feed lines may not be subjected to mechanical strains. Refer to the description

of the electrical supplementary components for this device.

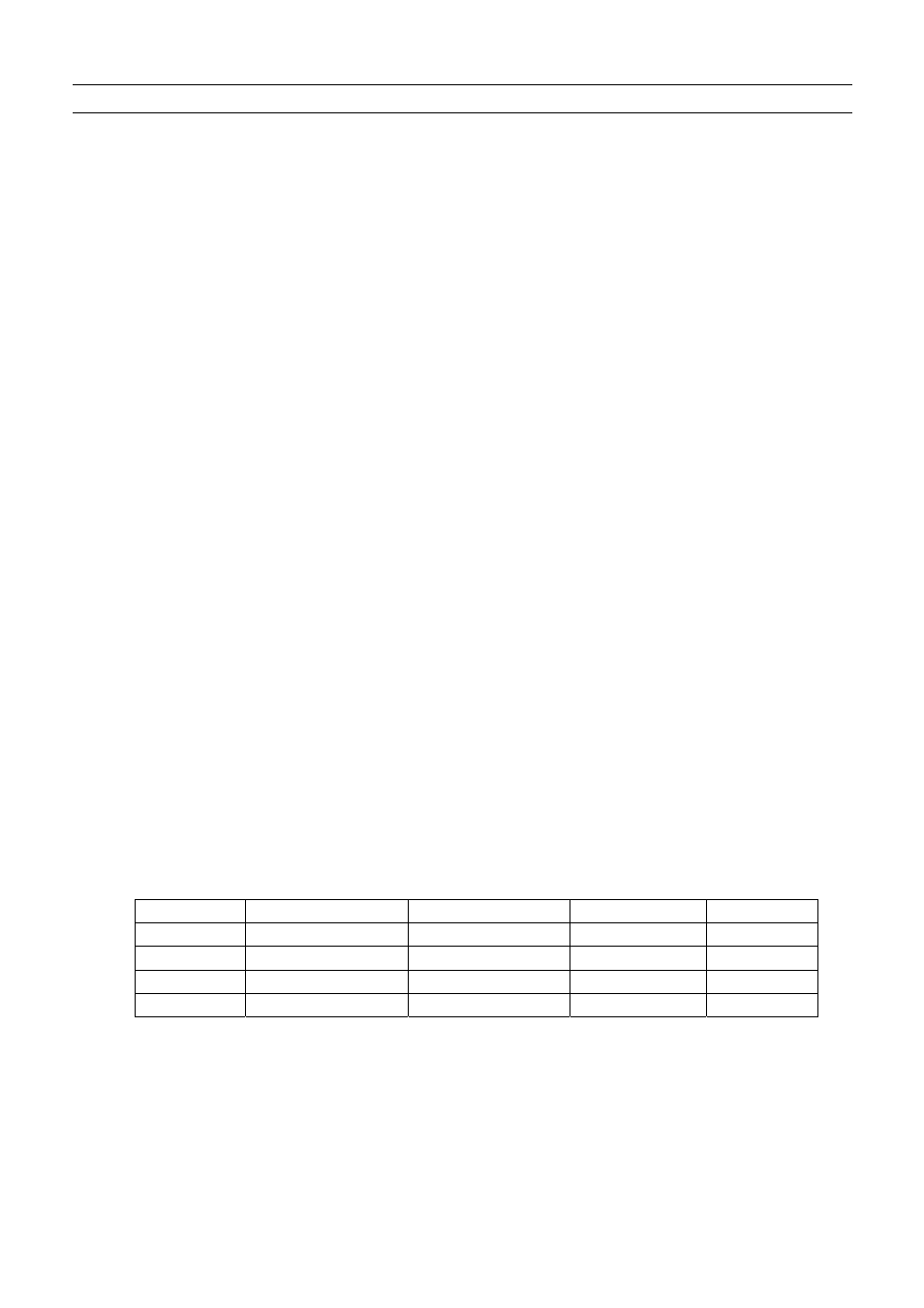

Cable glands / screwed glands:

Thread

Material

Line diameter

Degree of protect

Remark

M 16x1.5

PA

5 - 10 mm

IP 68 - 5 bars

Standard

M 20x1.5

PA

8 - 13 mm

IP 68 - 5 bars

M 16x1.5

Nickel-plated brass

5 - 9 mm

IP 68 - 5 bars

M 20x1,5

Nickel-plated brass

10 - 14 mm

IP 68 - 10 bar

* Degree of protection is limited here to the cable screwed gland