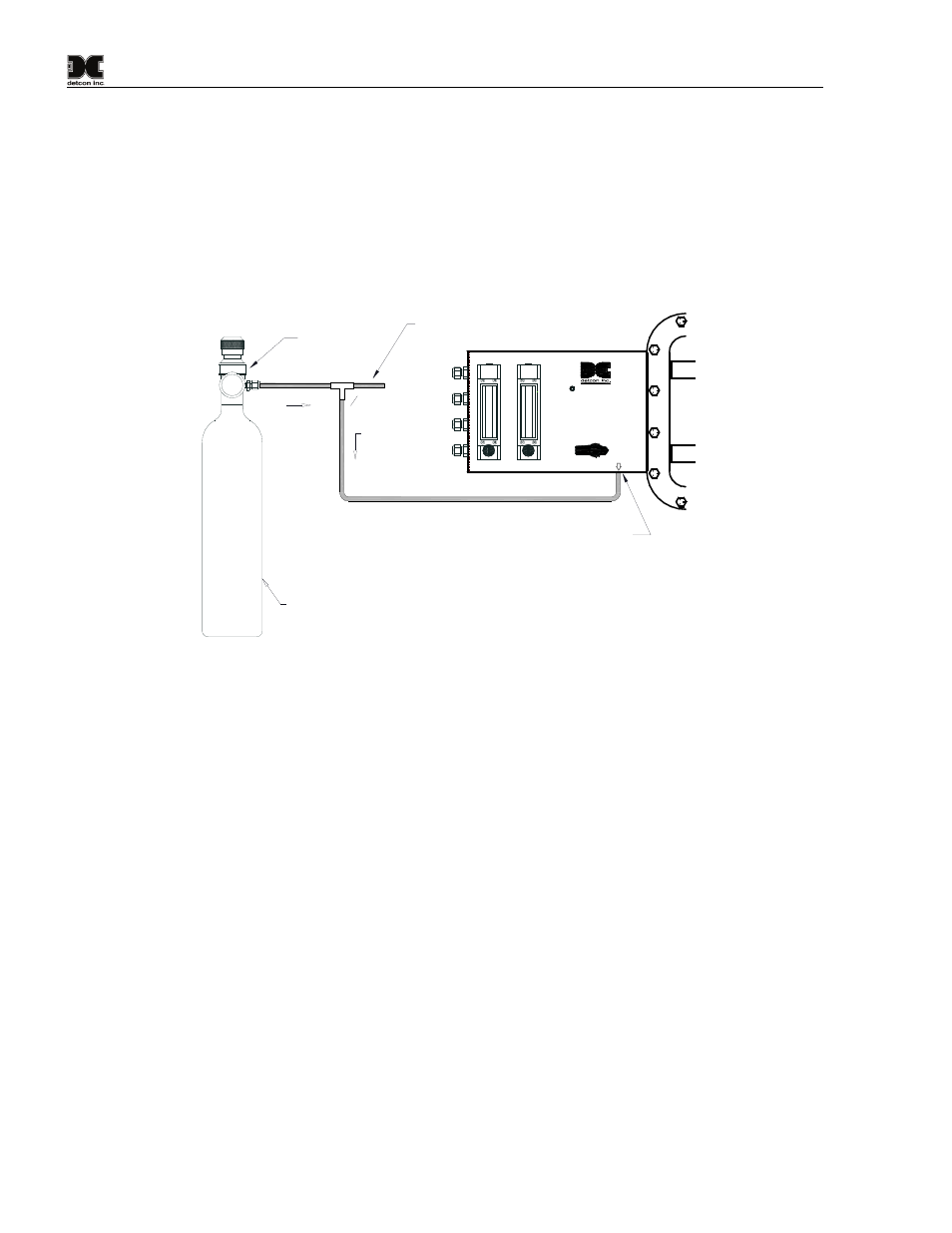

Calibration, Figure 4 calibration setup – Detcon 974-071170-BCR User Manual

Page 8

Ballast Monitor I.M.

Ballast Monitor Instruction Manual

Rev. 0.0

Page 4 of 8

4. Calibration

The Ballast Monitor and the attached sensor are calibrated prior to shipment and should require minimal

adjustment at the time of installation. However, it is recommended that a complete calibration is performed on

a periodic basis to assure optimum unit performance. Refer to the sensor’s instruction manual for gas type,

range, and sensor specific calibration instructions. Note that the sensor instruction manual requires the

removal of rain/splash guards for the application of gas. This requirement will be superseded by the

instructions below. The calibration adapter attached to the sensor head should not be removed during

calibration.

Fixed Flow

Regulator

6" of vent tube

CALIBRATION

Port

Teflon tubing

Span Gas

Cylinder

1000

ml/min

500 ml/min

SAMPLE

FLOW

BYPASS

FLOW

www.detcon.com

BALLAST GAS

DETECTION MONITOR

SAMPLE

CALIBRATE

SAMPLE

BYPASS

FLOW

1

4

" 'T' fitting

Figure 4 Calibration setup

Required material:

1. Span gas cylinder containing gas as per instructions in the sensor instruction manual.

2. 1/4" Tee tubing fitting as shown in Figure 4.

To Calibrate: (refer to Figure 4)

1) Turn the 3-way valve so that the arrow is pointing to the right. The sample is now being drawn from the

‘CALIBRATION’ port.

2) Using the 1/4" ‘T’ Calibration Setup, connect the span gas cylinder to the calibration port. Note that the

cylinder flow rate should be 1000 ml/m while the sample draw flow rate should be adjusted from 100- 500

ml/m. This will assure that the sample is not diluted. Be sure to add 6” of vent tubing as shown to prevent

dilution.

3) Follow the calibration instructions given in the sensor instruction manual.

4) Close cylinder valve to allow clearing/zero stability. Note that zero and span functions may interact

slightly with one another. Zero and span tests may be repeated 2 or 3 times as necessary.

5) When calibration is complete turn the 3-way valve so that the arrow is pointing toward “SAMPLE” it

ensure proper normal operation of the Ballast Monitor.