Figure 3 flow fault pca – Detcon 974-071170-BCR User Manual

Page 7

Ballast Monitor I.M.

Ballast Monitor Instruction Manual

Rev. 0.0

Page 3 of 8

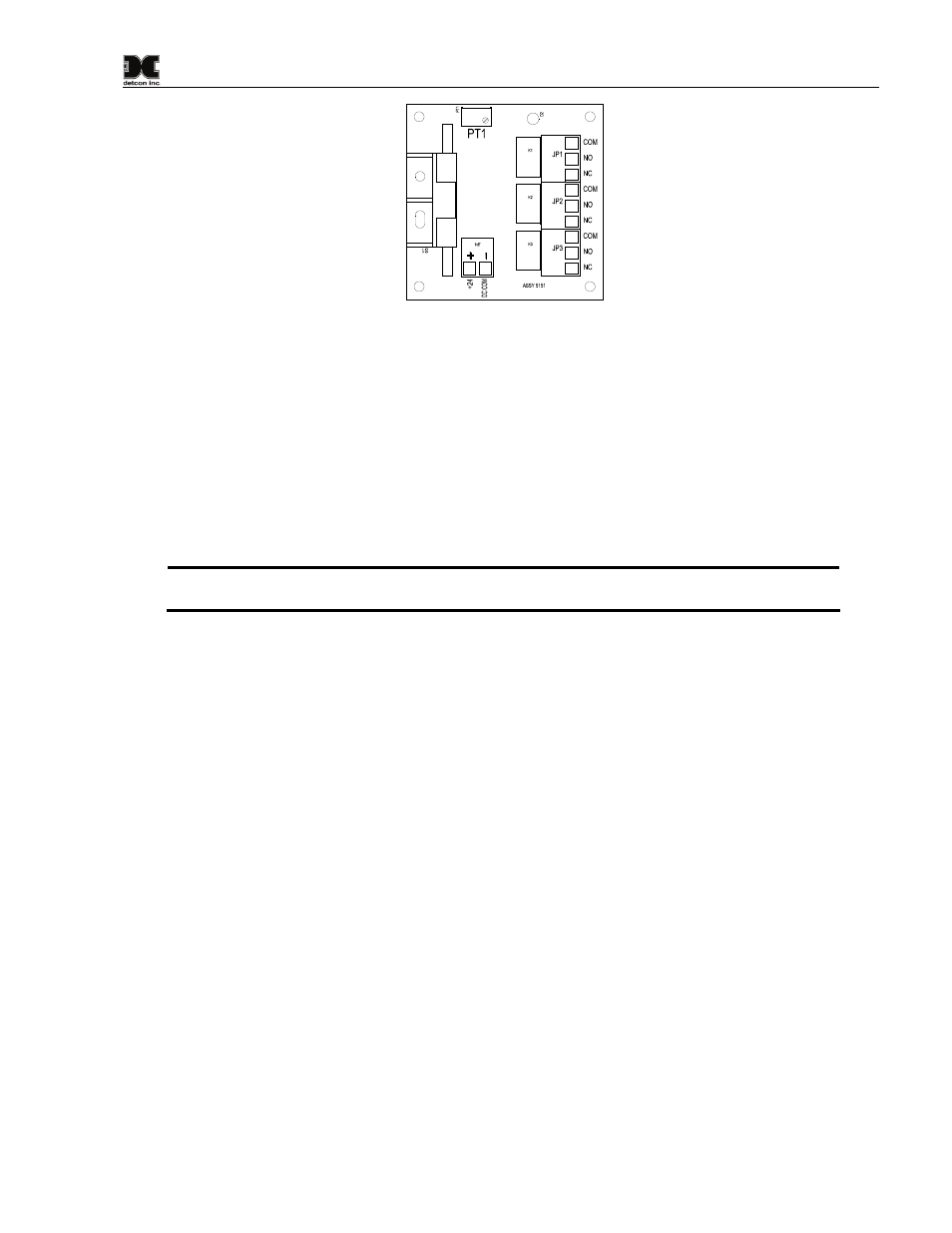

Figure 3 Flow Fault PCA

Adjusting the Flow Fault PCA trip point:

1. Completely close the Bypass Rotameter to ensure that it does not affect the reading of the Flow

Rotameter.

2. Use the Sample Flow Rotameter to set the air flow at the point where the fault condition should

activate.

3. Turn the flow fault adjust potentiometer (PT1 in Figure 3) clockwise until the flow fault LED (D2)

illuminates and the associated relays fire. Make adjustments as necessary by increasing and

decreasing airflow until the flow fault function occurs at the desired set point. Once the flow fault

circuit has been set, return the air flow to between 500 and 1000 ml/m.

Note: Because sample and vent tubing can become congested over a period of time, the flow

fault function should be checked periodically and adjusted as necessary.

4. When the Flow Fault adjustment is complete, reset the Bypass Rotameter to the original setting.

5. The Bypass Rotameter should take the majority of the flow (about 2-2.5Lpm), while the Sample Flow

Rotameter should be set to the target of 500ccm. Use each of the flow valves to achieve these settings.