Flow fault circuit, Flow fault contacts, 2 start up – Detcon 972-071170-0LC User Manual

Page 4: 3 flow fault detection

1.2 START UP

Upon completion of all tubing connections and field wiring turn on the power switch located on the enclo-

sure door. Note that the power lamp illuminates. If applicable, note that the sensor LCD indicators activate.

Varying readings may occur during sensor warm-up. Allow approximately 1 hour to stabilize (24 hours is best).

Also note air flow through the flow meter. Adjust the flow meter as necessary so that it falls between 500

and 1000 ml/m (milli liters per minute).

Assure that all field tubing connections are secure by obstructing the end of the sample line and observ-

ing that the flow meter decreases to “0” flow.

1.3 FLOW FAULT DETECTION

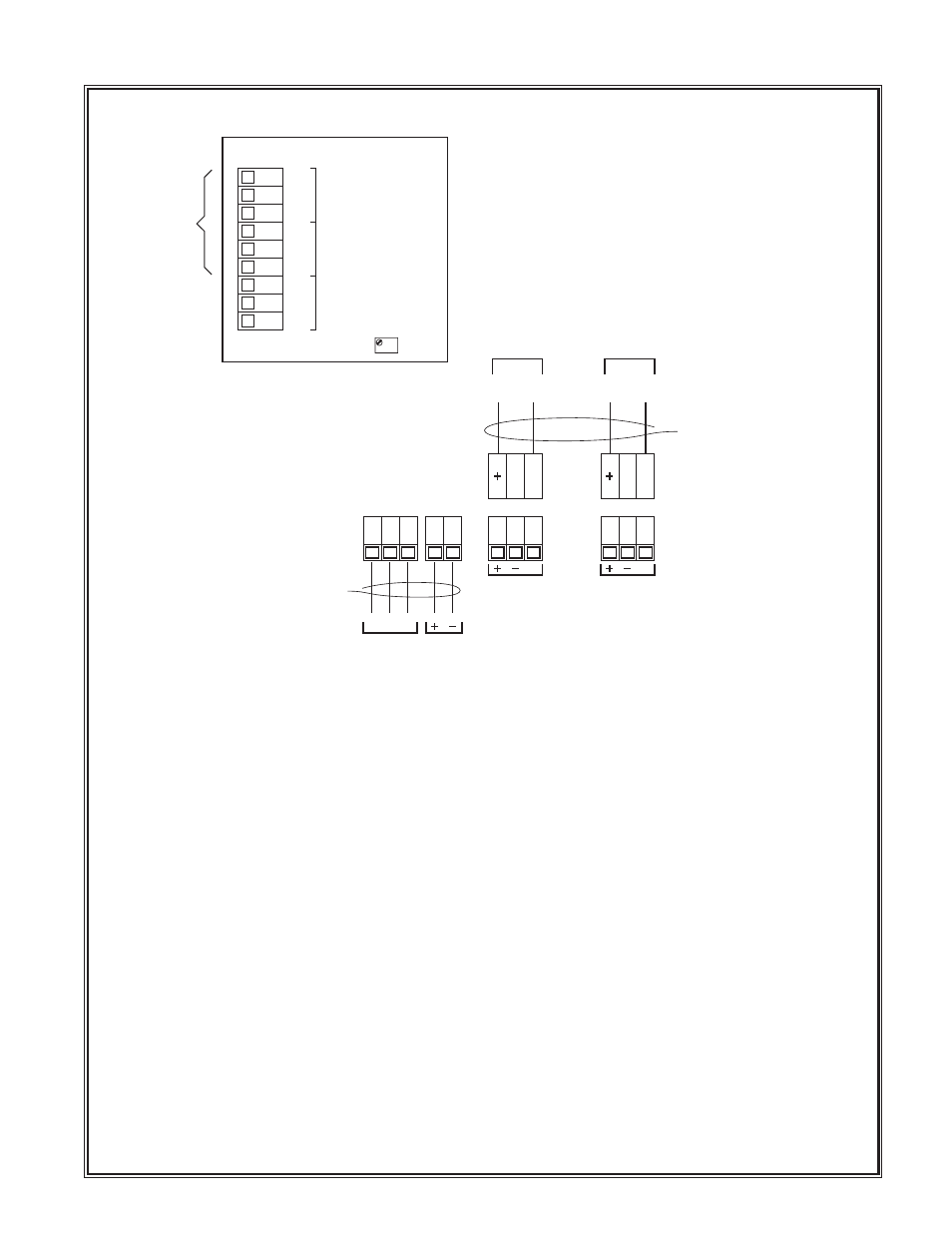

Flow fault detection consists of a flow fault circuit assembly located inside the enclosure and a door mount-

ed fault indicator lamp. If the air flow falls below a predetermined set point the following will occur: the

flow fault alarm relays will energize; an LED indicator mounted on the flow fault PCB will illuminate; the

door mounted flow fault lamp will illuminate; the 4-20mA signal will be opened via relay #1 on the flow

fault circuit board (this will allow for flow fault programming at the remote recording device or computer.

Because the pressure inside the sample and vent flow tubing differs according to the tubing length , the

flow fault circuit will require calibration after installation.

To calibrate the flow fault circuit, first determine at what point it is desired that the flow fault circuit is

Detcon Model 972-071170-0LC Gas Detection System PG.4

P7

P6

P5

L1 L2 GND

mA

117 VAC

IN

24 VDC

IN

Battery

Backup

SENSOR #1

Flow

Fault

Circuit

COM

NO

NC

1

COM

NO

NC

2

COM

NO

NC

3

PT1

mA

Signal

Loop

Wire signal loop to controllers

“+” to “Sensor +” on controller

“mA” to “Sensor mA” on controller

Wire 117 VAC & optional 24 VDC

backup to the lugless connectors.

Two discreet form C dry contacts

are provided (2 & 3) by the flow

fault circuit for alarm devices. The

first set of contacts (1) are

prewired to interrupt the 4-20mA

signal output in the event of a

flow fault. This will allow for flow

fault monitoring at any

controller/computer that the signal

is wired in to.

P7

mA

SENSOR #2

mA

Signal

Loop

FLOW

FAULT

CONTACTS