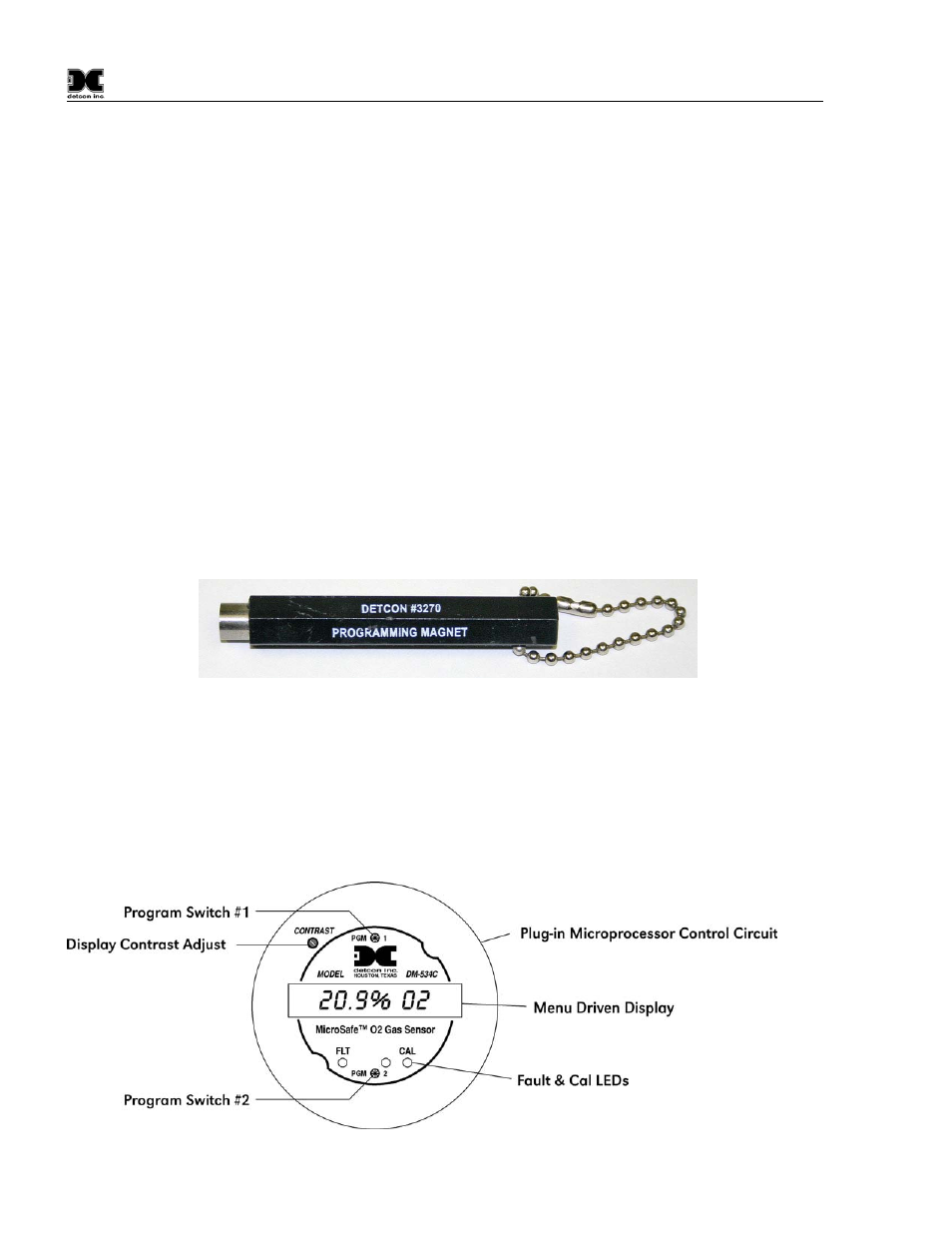

0 calibration, Calibration, Figure 10 magnetic programming tool – Detcon DM-534C User Manual

Page 14

DM-534C Oxygen Sensor Assembly

DM-534C O2 Sensor Instruction Manual Rev.1.4

Page 10 of 18

b) b) Remove the test gas and observe that the LCD display increases back to 20.9% ±2% of scale (0.5%

O2).

c) Initial operational tests are complete. Detcon O2 gas sensors are pre-calibrated prior to shipment and

will, in most cases, not require significant adjustment on start up. However, it is recommended that a

complete calibration test and adjustment be performed within 24 hours of installation. Refer to

calibration instructions in section 8.0.

8.0 CALIBRATION

Material Requirements

-Detcon PN 327-000000-000 MicroSafe™ Programming Magnet

-Detcon PN 613-120000-000 Splash Guard with integral Cal Port -OR-

-Detcon PN 943-000006-132 Threaded Calibration Adapter

-Detcon PN 942-001123-000 Zero Air cal gas or use ambient air if no combustible gas is present.

Programming Magnet Operating Instructions

Operator interface to MicroSafe™ gas detection products is via magnetic switches located behind the

transmitter face plate. DO NOT remove the glass lens cover to calibrate or change programming parameters.

Two switches labeled “PGM 1” and “PGM 2” allow for complete calibration and alarm level programming

without removing the enclosure cover, thereby eliminating the need for area declassification or the use of hot

permits.

Figure 10 Magnetic Programming Tool

A magnetic programming tool (see Figure 10) is used to operate the switches. Switch action is defined as

momentary contact, 3-second hold, and 30-second hold. In momentary contact use, the programming magnet

is waved over a switch location. In 3 second hold, the programming magnet is held in place over a switch

location for 3 or more seconds. In 30 second hold, the programming magnet is held in place over a switch

location for 30 or more seconds. Three and thirty second hold is used to enter or exit calibration and program

menus while momentary contact is used to make adjustments. The location of “PGM 1” and “PGM 2” are

shown in figure 6.