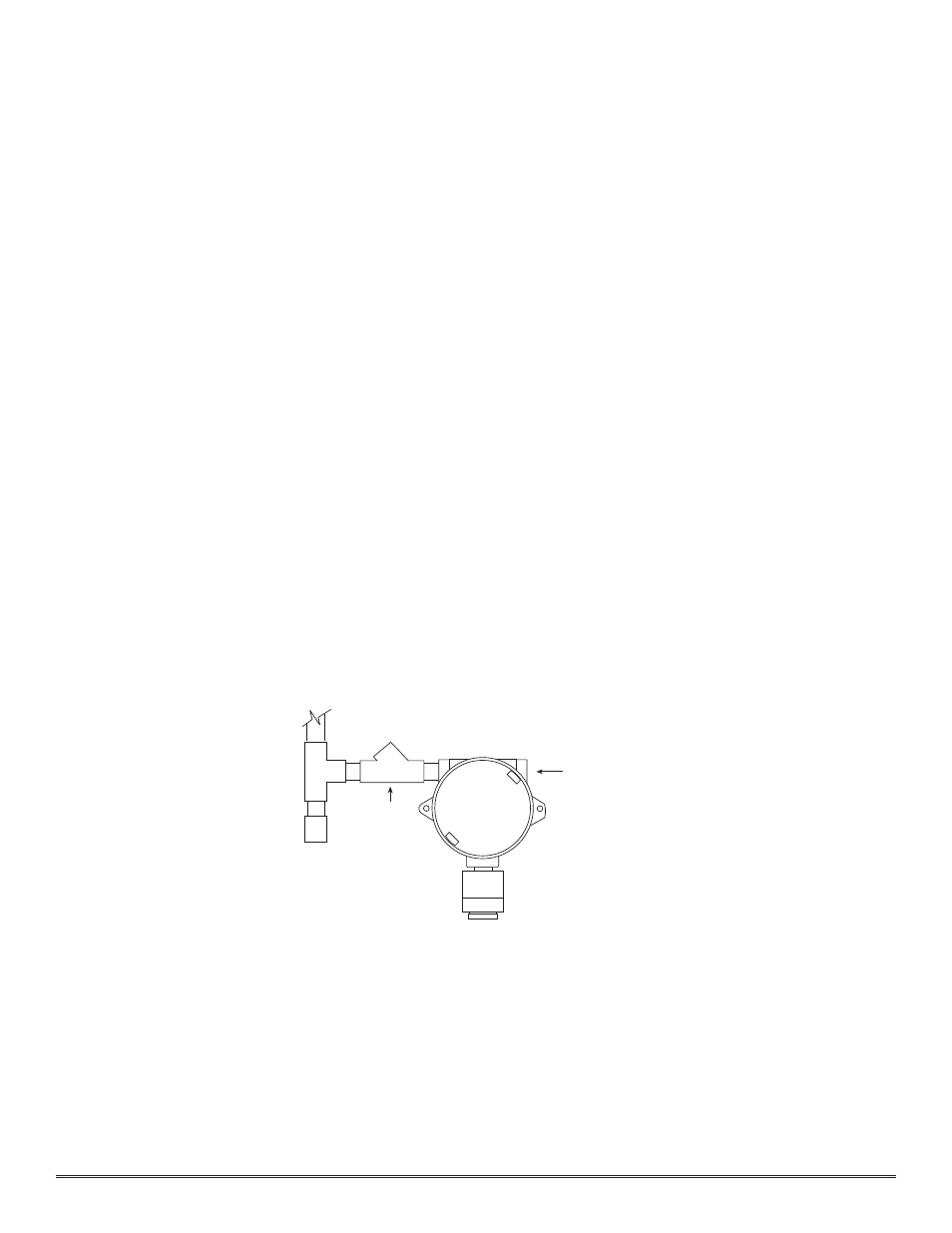

Figure #1 – Detcon IR-622 User Manual

Page 9

3.5.2 Sensor Location

Selection of sensor location is critical to the overall safe performance of the product. Five factors play an important

role in selection of sensor locations:

(1) Density of the gas to be detected

(2) Most probable leak sources within the industrial process

(3) Ventilation or prevailing wind conditions

(4) Personnel exposure

(5) Accessibility for routine maintenance

Density - Placement of sensors relative to the density of the target gas is such that sensors for the detection of

heavier than air gases should be located within 2-4 feet of grade as these heavy gases will tend to settle in low lying

areas. For gases lighter than air, sensor placement should be 4-8 feet above grade in open areas or in pitched areas

of enclosed spaces.

Leak Sources - Most probable leak sources within an industrial process include f langes, valves, and tubing connec-

tions of the sealed type where seals may either fail or wear. Other leak sources are best determined by facility engi-

neers with experience in similar processes.

Ventilation - Normal ventilation or prevailing wind conditions can dictate efficient location of gas sensors in a

manner where the migration of gas clouds is quickly detected.

Personnel Exposure - The undetected migration of gas clouds should not be allowed to approach concentrated per-

sonnel areas such as control rooms, maintenance or warehouse buildings. A more general and applicable thought

toward selecting sensor location is combining leak source and perimeter protection in the best possible configuration.

Note: In all installations, the sensor element in SS housing points down relative to grade (Fig. 1). Improper sensor

orientation may result in false reading and permanent sensor damage.

3.5.3 Local Electrical Codes

Sensor and transmitter assemblies should be installed in accordance with all local electrical codes. Use appropriate

conduit seals. Drains & breathers are recommended. The sensor assemblies are designed to meet NEC and CSA

requirements for Class I; Groups B, C, D; Div. 1 environments.

3.5.4 Accessibility

Consideration should be given to easy access by maintenance personnel as well as the consequences of close prox-

imity to contaminants that may foul the sensor prematurely.

Note: An appropriate conduit seal must be located within 18" of the sensor assembly. Crouse Hinds type EYS2,

EYD2 or equivalent are suitable for this purpose.

3.5.5 Installation Procedure

Note: See section 3.5.6 for special information on remote mounting applications in which the sensor (Model IR-

622-RS) is remotely mounted away from the transmitter (Model IR-622-RT).

Detcon Model IR-622 Combustible Hydrocarbon Sensor PG.9

EYS

Seal

Fitting

Drain

“T”

Plug any unused ports.

Figure #1