Detcon IR-622 User Manual

Page 5

The sensors are packaged in a cast metal explosion proof enclosure. The enclosure is f itted with a threaded cover

that has a glass lens window. Magnetic program switches located behind the transmitter module face plate are acti-

vated through the lens window via a hand-held magnetic programming tool allowing non-intrusive operator inter-

face with the sensor. All calibration and alarm level adjustments can be accomplished without removing the cover

or declassifying the area. Electrical classif ication is Class I; Groups B, C, D; Div. 1.

3.1 P

RINCIPLE OF

O

PERATION

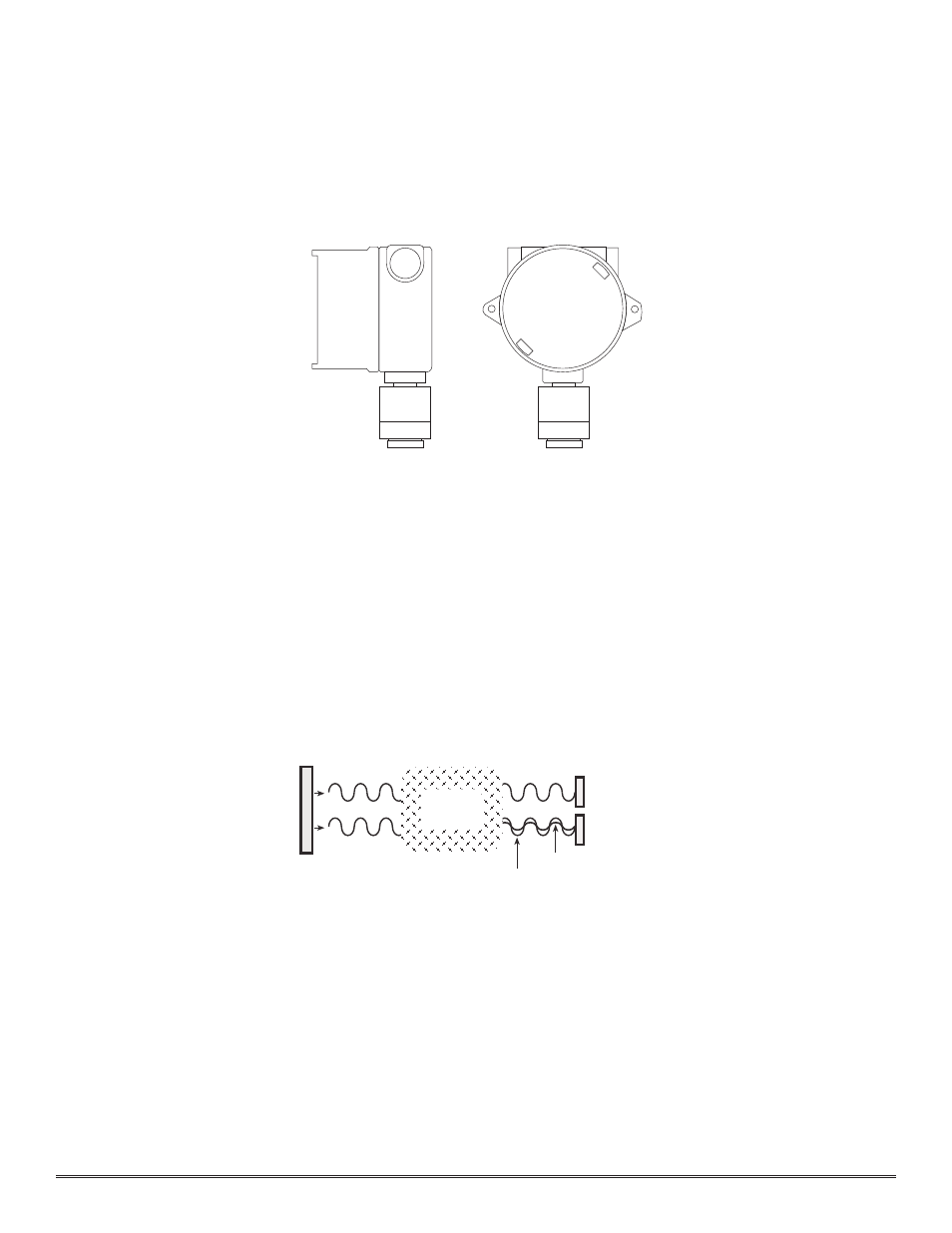

The target gas diffuses through a sintered stainless steel f lame arrestor and into the volume of the sample gas opti-

cal cavity. A lamp source provides a cyclical IR radiation source which travels through the optical gas sample cavity

and terminates at two pyroelectric detectors. The “active” and “reference” pyroelectric detectors each give an output

which measures the intensity of the radiation contacting their surface. The “active” pyroelectric detector is covered

by an optical f ilter specif ic to the part of the IR spectrum where the target gas absorbs light. The “reference” pyro-

electric detector is covered by a f ilter specif ic to the non-absorbing part of the IR spectrum. When present, the tar-

get gas absorbs a fraction of the IR radiation and the signal output from the “active” pyroelectric detector decreases

accordingly. The signal output of the “reference” detector remains unchanged in the presence of the target gas. The

ratio of the “active” and “reference” detector signal outputs is then used to compute the target gas concentration.

By using the ratio of the active/reference signal outputs, measurement drift caused by changes in the intensity of

the lamp source and changes in the optical path are negated.

3.1.2 Characteristics

The NDIR optical sensor element maintains strong sensitivity to combustible hydrocarbon gases in air in the lower explo-

sive range (0-100% LEL), as shown in the illustration below. When compared with the typical catalytic bead LEL sensor,

the NDIR sensor exhibits excellent long-term zero and span stability. Typical zero calibration intervals would be monthly

to quarterly and typical span calibration intervals would be semi-annual to annual. However, actual field experience is

always the best determination of appropriate calibration intervals.

NOTE: The IR-622 detector will not respond to combustible gases such as H2, NH3, CO, etc, which are not hydrocarbons.

The MicroSafe™ IR-622 is factory calibrated for a specific target gas. Unless otherwise specified, the detector will be factory

calibrated for methane service. If a combustible hydrocarbon gas other than methane is being measured, contact Detcon for

the appropriate field-replaceable electronics/software upgrade.

The NDIR optical sensor readings can be adversely affected by dust, dirt and oil mist accumulation as well as severe corro-

sion. These deposits may reduce the optical reflectivity inside the sensor, and although accurate readings are continually main-

Detcon Model IR-622 Combustible Hydrocarbon Sensor PG.5

IR Lamp Source

Reference Detector Output

Active Detector Output

Target Gas Not Present

Gas Present

Principle of Operation

Sample

Gas