Troubleshooting guide – Detcon TP-700 User Manual

Page 34

Model TP-700

TP-700 Instruction Manual

Rev. 3.5

Page 30 of 38

6. Troubleshooting Guide

Refer to the list of Failsafe Diagnostic features listed in Section 3.6.2 for additional reference in

troubleshooting activities. Listed below are some typical trouble conditions and their probable cause and

resolution path.

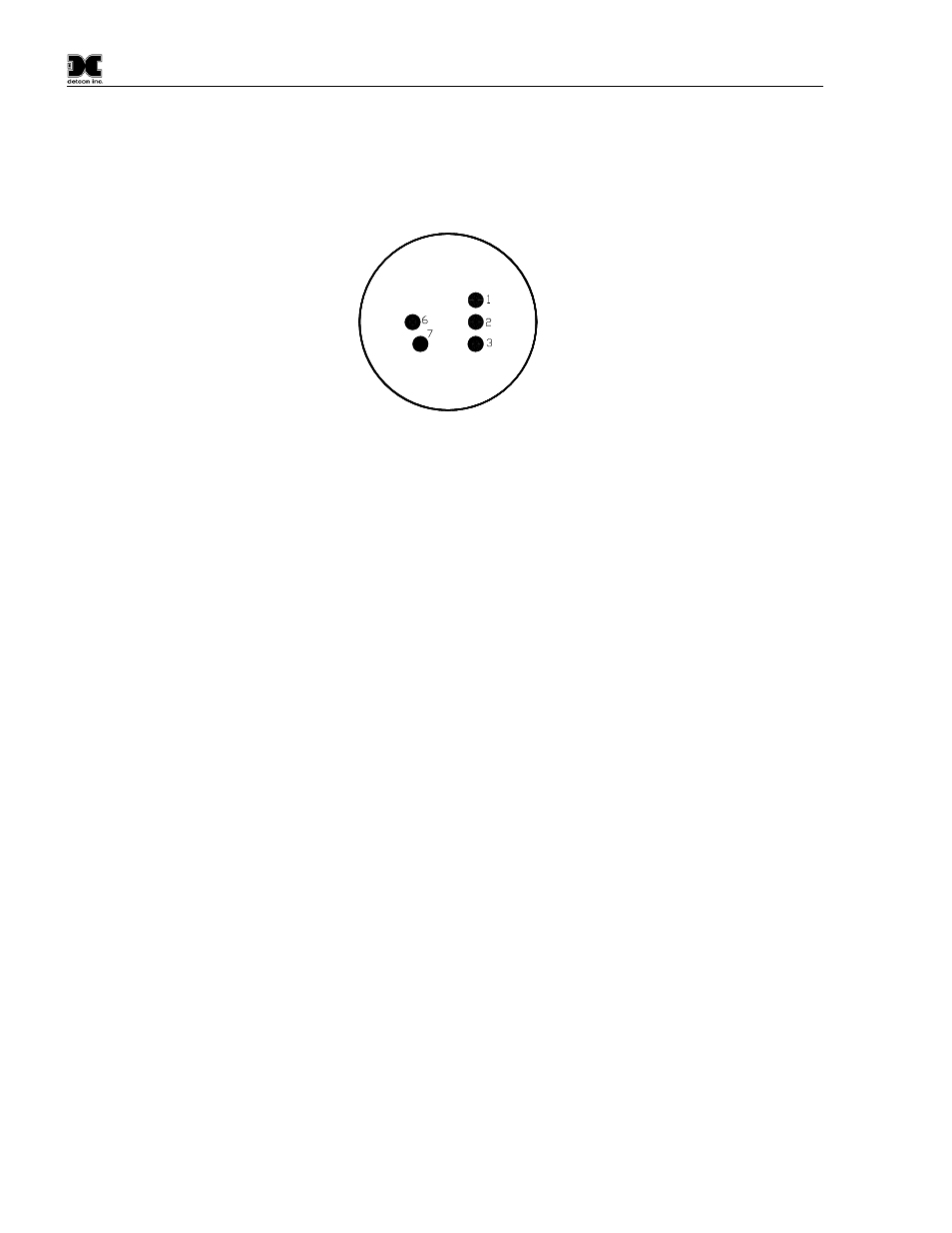

Figure 13 Sensor PCB

Open Heater

Probable Cause: Plug-in sensor has failed

Remove plug-in H

2

S sensor and verify resistance between PIN 2 and PIN 3 (Shown in Figure 13)

using an ohmmeter. At room temperature, the heater film’s normal reading should range between 65

and 95 ohms.

Replace the plug-in H

2

S sensor if open circuit or significantly out-of range readings are found.

Open Sensor

Probable Cause: Plug-in sensor has failed

Remove plug-in H2S sensor cell and verify resistance between PIN 6 and PIN 7 (Shown in Figure 13)

using an ohmmeter. At room temperature, the sensor film’s normal reading range should be 10-100 k-

ohms. For sensors with an “X” in the serial number, the normal reading range should be 75 k-ohms to

2 meg-ohms. Failure would be open circuit.

Replace the plug-in H

2

S sensor cell if an open circuit found.

AutoSpan Calibration Faults – (Range, Stability and Clearing)

To clear any AutoSpan Calibration fault, the AutoSpan process must be completed successfully (Section3.4).

Range Fault

Probable Causes: Failed Sensor, Cal Gas not applied or not applied at appropriate time, problems w/ cal gas

and delivery, no Humidifying Tube used, failure to properly desiccant packet the sensor cell during extended

power-off periods.

Check Heater Power Setting (should be 235 +/- 5mW at 25ºC ambient temperature).

Verify use of span gas Humidifying Tube.

If using Splashguard with Integral Cal Port, must use Calibration Wind Guard or air movement can

compromise span gas delivery.

Check validity of span gas using H

2

S pull tube or other means (check MFG date on cal gas cylinder).

Check for obstructions through stainless steel flame arrestor (including being wet, blocked, or

corroded).