Introduction, Introduction operation overview operation overview, Power-up / power-down – DeFelsko PosiTector 200 v.1.2 User Manual

Page 3

Page 3

Introduction

Introduction

Operation Overview

Operation Overview

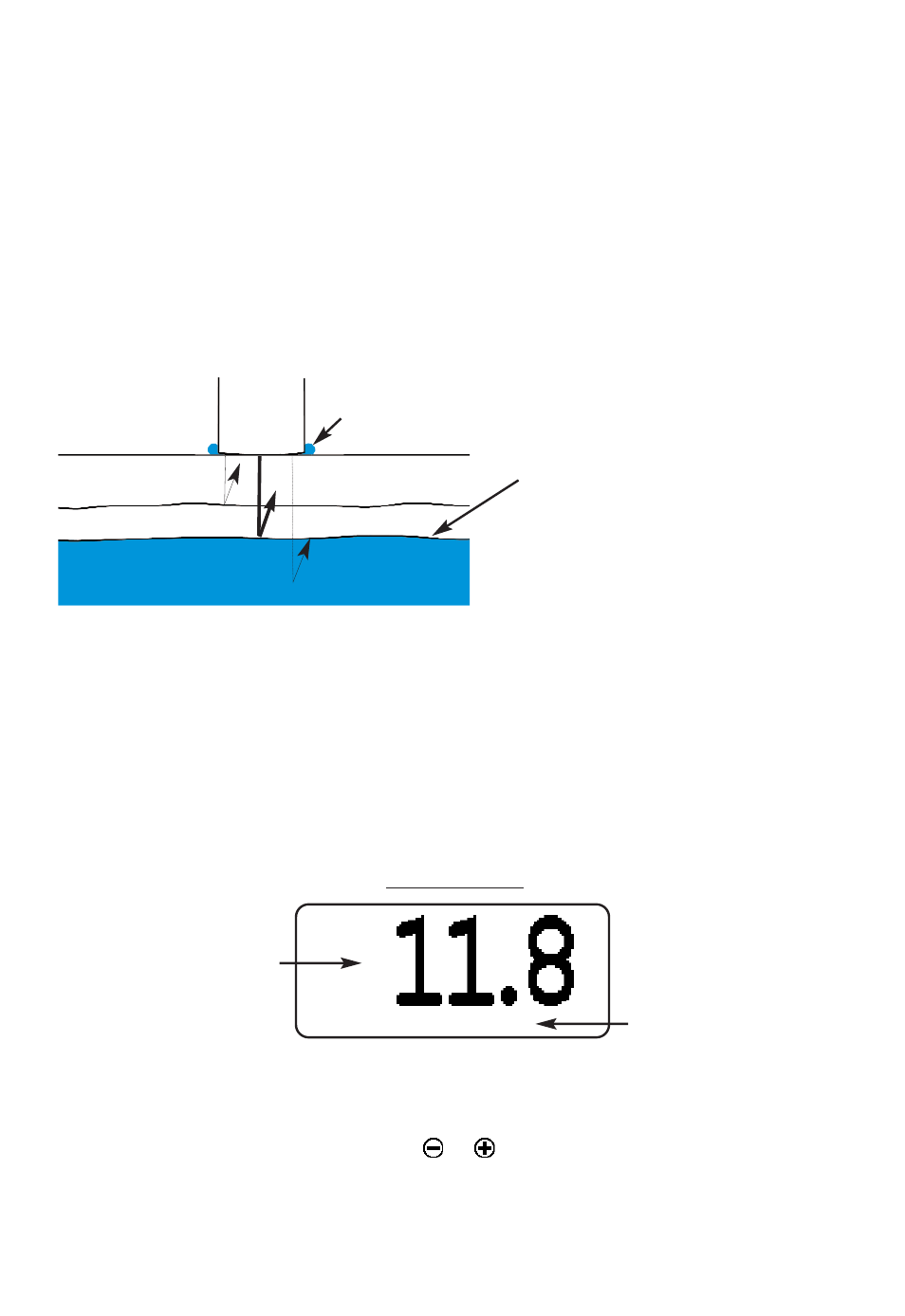

The PosiTector 200 is a hand-held Coating Thickness Gage that uses a non-

destructive ultrasonic principle to measure coating thickness on a wide variety of

substrates.

The PosiTector 200 probe emits a high frequency sound pulse that travels into the

coating via a coupling gel and reflects from ANY surface that is different in density.

Coating thickness readings are obtained by measuring the time taken for the

ultrasonic signal to propagate from the probe to the coating/substrate interface and

back. The travel time is divided by two and multiplied by the velocity of sound in the

coating to obtain the thickness of the coating.

1.

Turn the Gage ON

(see Power-Up below)

2.

ZERO the probe

(see pg.6)

3.

ADJUST to a known thickness, if necessary (see pg.7)

4.

MEASURE the part

(see pg.4)

Typical Display

Current Measurement

thou/mils

Unit of Measurement

Power-up / Power-down

Power-up / Power-down

The PosiTector 200 powers-up when or is pressed. On power-up dashes are

displayed. To preserve battery life, the Gage powers-down after a period of no

activity. To power-down manually, hold both buttons down for at least 5 seconds. All

settings are retained during power-down.

The PosiTector 200 interprets the

largest “echo” within the Gates as

the coating/substrate echo.

Couplant

Probe

Coating

Substrate

Primer