Extractive installation – COSA Xentaur Xentaur XDTL-HT User Manual

Page 11

Installation

11

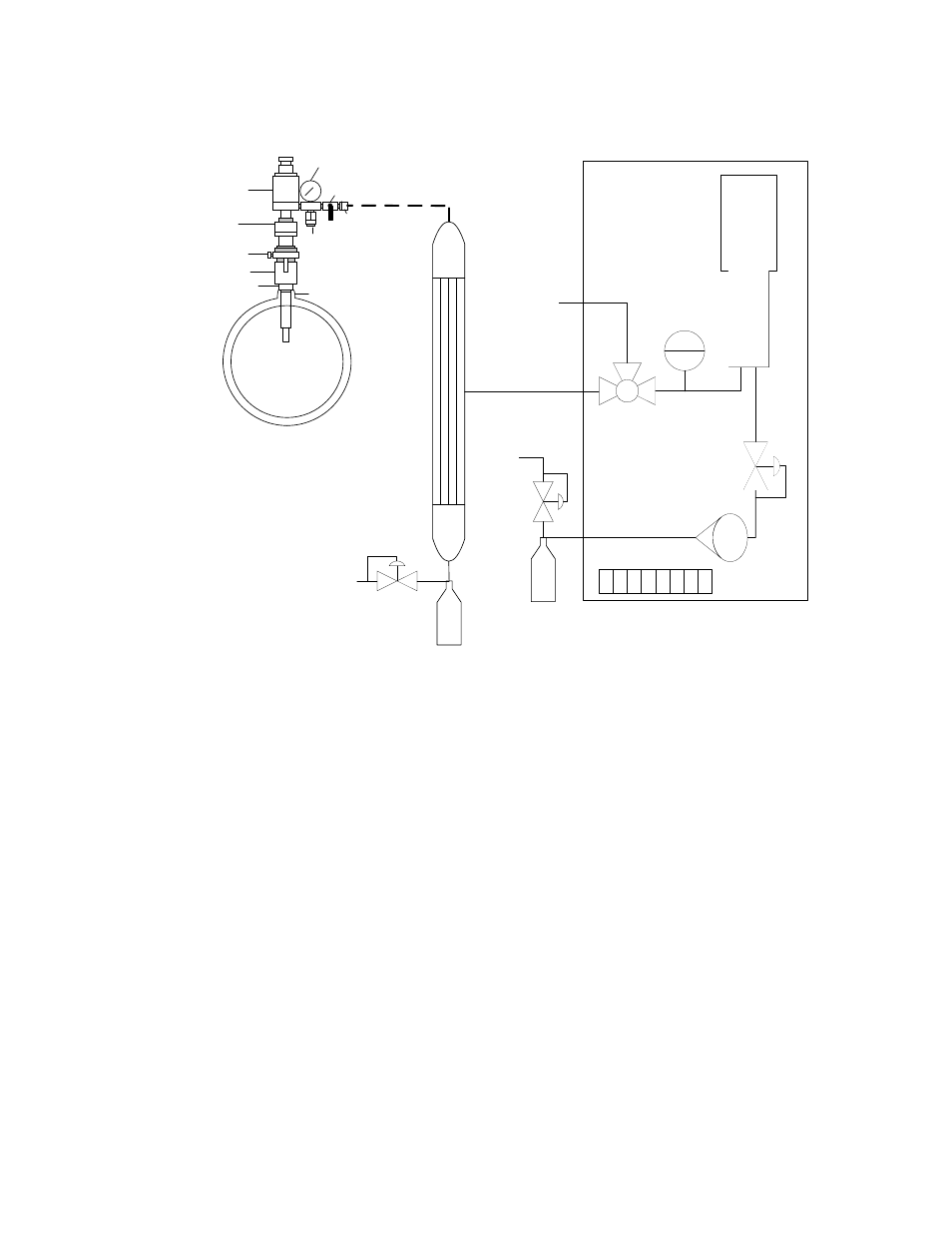

Extractive Installation

Enclosure

1

6

4

8

9

Calibration

Gas Inlet

Process

Gas Inlet

Sample

Gas

Exhaust

7

pipeline

Pipe Nipple

Thredolet

Ball Valve

Baseplate

Housing

Regulator

Relief Valve

Ball Valve

Outlet Connector

Pressure Gauge

Notes:

Enclosure insulated on all sides to

maintain nomially 34°C ± 1°C in a

temperature range of -20°C to 50°C.

Inlet rated to 6000 psig maximum.

Flow rate is 2 l/min nominal.

All ¼” Swaglok fittings and tubing.

Shop Air

Inlet

Shop Air

Inlet

Sample

Gas

Exhaust

5

5

2

2

10

1. Back pressure regulator

5. Adjustable regulator

9. Pressure gauge (0-30 psig)

2. Eductor

6. 3-way valve

10. Gas sampling filter

3. All ¼” stainless steel tubing

7. XTDL-HT™ laser cell

4. Flow meter

8. Enclosure heater

The instrument should be installed in a slip stream of process gas. Please make sure that:

The sample is taken from the upper surface of the main gas line to avoid problem of

contamination.

The sample is taken away from the pipe wall where flow rates may be low, and dewpoint change

may lag.

If regulators or shut-off valves are used up stream of the instrument, make sure that these do not

contain rubber or other hygroscopic materials.

Stainless steel tubing is preferred. Copper tubing is acceptable. Do not use plastic, rubber, or

Tygon tubing due to water retention in these materials.

Use small diameter pipes (1/4” or 1/8” OD).

Do not install other devices up stream of the instrument, such as other measurement systems,

which are not absolutely necessary as these are potential leak sources.