Appendix f: sensor/spancheck™ theory of operation, Xdt user’s manual appendices 43 – COSA Xentaur Xentaur XDT User Manual

Page 50

XDT User’s Manual Appendices

43

Appendix F: Sensor/SpanCheck™ Theory of Operation

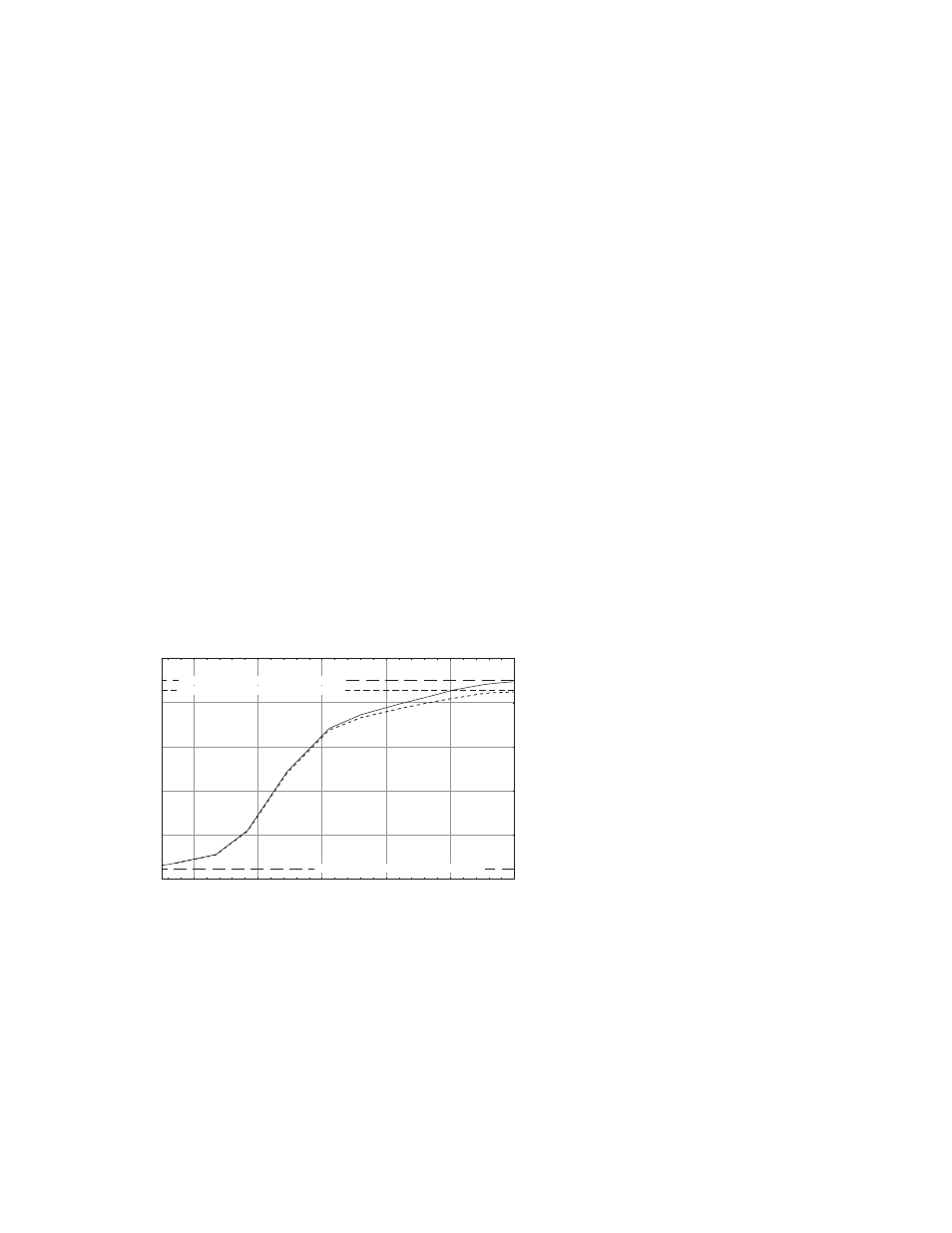

The Sensor is constructed as a capacitor whose dielectric consists of porous Aluminum Oxide as

well as the gas that has entered in the pores of the Aluminum Oxide. The plates (electrodes) of

this capacitor are an aluminum substrate and a porous gold layer deposited on top of the Alumi-

num Oxide, the porous gold electrode allows transfer of gases into or out of the Aluminum Oxide

pores.

The capacitance due to the Aluminum Oxide is always constant, while the capacitance due to the

gas varies according to the gas content and pressure. Since the dielectric constant of water is

orders of magnitude larger than that of any gases being measured, the quantity of water vapor

present in the pores changes the capacitance of the sensor to a much greater extent than any other

system variable. For the same reason (the extremely large dielectric constant of the water mole-

cule), any capacitance variations arising from the Aluminum Oxide, such as changes due to tem-

perature, are insignificant in relation to the capacitance due to the water content. Thus the sensor

capacitance varies greatly in proportion to the water content in the surrounding gas. The sensor is

designed such that the relationship of the quantity of water and the resultant capacitance has an

"S" shaped curve. At the extremely dry end the curve is asymptotic to the capacitance due to the

Aluminum Oxide and the gas, while at the very wet end the curve is asymptotic to the capacitance

due to water molecules packed extremely tightly (saturated) in the pores of the Aluminum Oxide.

This upper end is an excellent indication of the total pore volume; while the lower end of the

curve is an indication of the distance between, & area of the capacitor plates (electrodes), this is

the intrinsic capacitance of the sensor. Therefore knowing these two points, a sensor can be cali-

brated with compensation for small manufacturing deviations.

As the sensor is used in real world

applications, it is exposed to various

elements and stress; like any other sen-

sor it may over time drift from calibra-

tion. However one must note that the

intrinsic capacitance will not change

with use because it is based simply on

the dielectric constant of Al

2

O

3

and the

distance between, & area of the plates

(electrodes), thus the original factory

measured values will always be valid.

What may change is the pore volume,

due to clogging with contaminants,

residual oxidation, metal migration, etc.

Thus to re-calibrate the sensor the

instrument needs only to “know” the capacitance at the wet end of the curve. As discussed previ-

ously the capacitance at the wet end approaches asymptotically a saturated pore capacitance,

therefore if the sensor is saturated (the exact water content will not be important since the curve is

asymptotic), then the instrument can measure the capacitance and re-calibrate the sensor. This is

referred to as SpanCheck™.The advantages of this unique capability of Xentaur HTF™ sensors

and instruments are obvious in time and cost savings for re-calibration, as well as ease of sensor

replacement.

Xentaur HTF™ Sensor: Dewpoint vs. Capacitance Response Curve

Dewpoint Reference ˚C

Capacitance (nF)

Ne

w

S

en

so

r C

urv

e

Aged

Sensor

Curv

e

0

40

80

120

160

200

-80

-60

-40

-20

0

20

Saturated Capacitance Asymtote of Aged Sensor

Dry Capacitance Asymtote of New & Aged Sensor

Saturated Capacitance Asymtote of New Sensor