Hub-40ex sensor, User manual – AW Gear Meters HUB-40EX User Manual

Page 3

HUB-40Ex Sensor

User Manual

AW Gear Meters

8809 Industrial Drive, Franksville, WI 53126

web: www.awgearmeters.com

Tel: 262-884-9800

Fax: 262-884-9810

Email: [email protected]

HUB-40Ex User Manual rev1.2.docxError! Unknown document property name., 1/18/2012

PAGE: 3 of 4

Special installation instruction for use in Hazardous Area environments

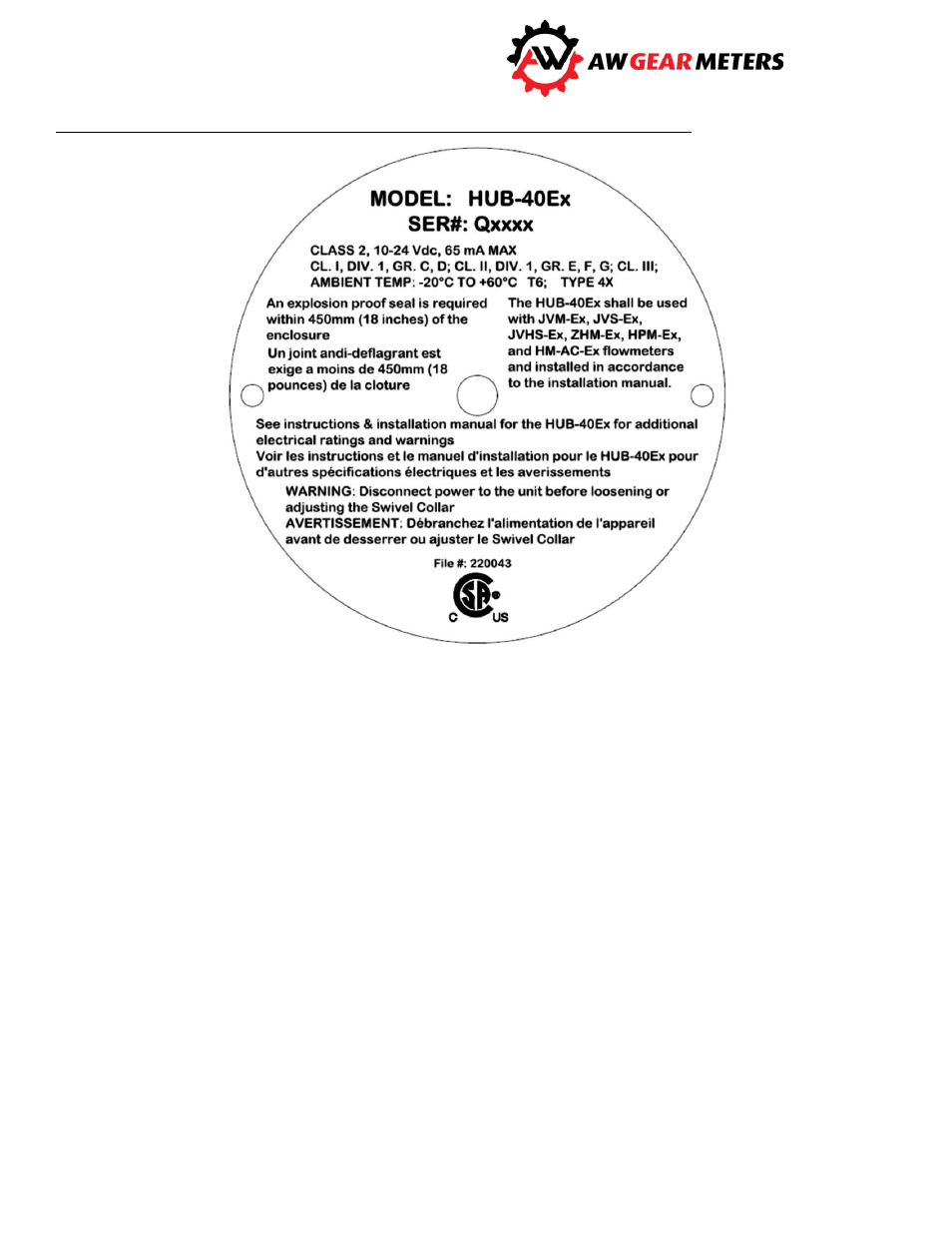

Figure 1: Hazardous Area certification tag

HUB-40Ex models are explosion-proof flow meter sensors, which may be used in Class I, Division 1 locations. Figure 1

above is a sample of the nameplate that should be clearly attached to each unit. Please make sure this nameplate is on

the unit and that the information matches what is shown above, prior to installation. If either the nameplate is not on the

unit or the unit nameplate does not match what is shown above, please notify AW-Lake Company to determine

appropriate course of action.

When installing the HUB-40Ex into an AW-Lake Company flow

meter make sure the 3/8” NPT male portion of the sensor

housing is engaged by a minimum of five (5) threads into the flow meter in order to maintain th

e unit’s explosion proof

rating. HUB-40Ex models must be properly installed into a flow meter before power is applied. NOTE: It is strongly

suggested to use anti-seize grease on threads prior to installation to avoid galling.

Because the HUB-40Ex uses an explosion proof enclosure for its area protection, power must be removed from the unit

before covers are detached and seals are disconnected while in a hazardous area.

For proper installation, it is also necessary that the conduit entries on the junction box are properly sealed. To maintain

the unit’s explosion proof rating, anything threaded into the NPT conduit openings must engage by a minimum of five (5)

full threads. Original units received from AW-Lake Company are properly installed with a minimum five (5) full threads of

engagement when connected to a junction box and should not be tampered with. NOTE: It is strongly suggested to use

anti-seize grease on threads prior to installation to avoid galling.

When wiring the unit, please make sure to observe any national or local codes that may be required. An explosion-proof

seal is required within 18 inches (450mm) of the unit. Make sure units are powered by a Class 2 power supply for proper

regulation. NOTE: Power must be removed from the unit before the Swivel Collar on the hub adapter can be loosened or

adjusted.

Removal of the external housing ground terminal is not permitted for safety reasons. Please make sure to follow local

electrical code practices when installing equipment in hazardous areas.