Installation (cont'd.), Maintenance, Trouble shooting – Van Air Systems AHP High Pressure Alloy Filter Series IOM User Manual

Page 3: Warning

PAGE 3

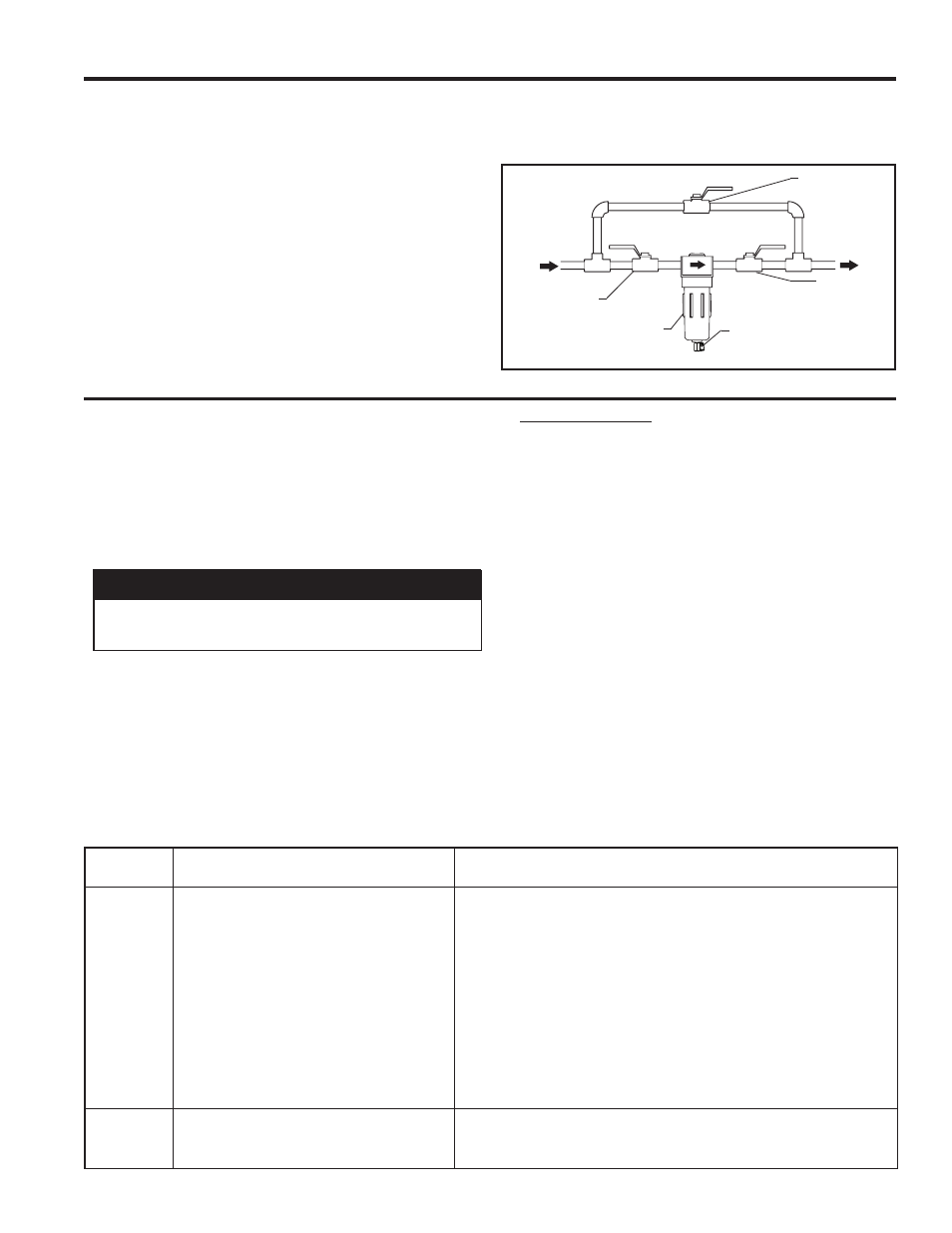

FIGURE 1A BYPASS PIPING

INSTALLATION (Cont'd.)

INLET

SHUTOFF

VALVE

FILTER

OUTLET

SHUTOFF

VALVE

9. Check to make sure that the housing o-ring is in the

proper position. Thread filter bowl into filter head and tighten

either by hand (models AHP-25 through 40) or with strap

wrench (models AHP-65 through 470). Do not over tighten.

Overtightening could damage filter bowl or make it difficult

to remove.

10. Install a drain valve (customer supplied) rated for the filter

MWP into the drain connection and make sure drain valve is

closed. If a drain valve is not used, install the drain plug into

the filter bowl drain connection and tighten.

11. Pressurize system and

SLOWLYopen inlet and outlet shutoff

valves.

12. Check piping for leaks. Depressurize system and repair

leaks as needed.

13. Re-pressurize system and slowly open inlet and outlet

shutoff valves.

14. Filter is now in service.

MAINTENANCE

Drain coalescing filters every shift.

Check differential pressures weekly on coalescing and par-

ticulate filters (AA, A, B, C, RA, RB, and RC grades). When

indicator is in the red, install clean elements. On adsorbing

filters (grade RD), install clean elements when hydrocarbon

vapors are first detected downstream or every six months,

whichever comes first.

•

•

CHANGE ELEMENT

TROUBLE SHOOTING

CONDITION

POTENTIAL CAUSE

RECOMMENDATION

Oil carryover

Oil present in system before installing filter.

Clean piping.

Excessive inlet oil >50ppm.

Check compressor and/or gas/oil separator if compressor is rotary vane or screw type.

Check lube rate if reciprocating compressor. Install coarse coalescer for prefiltration.

Filter installed backwards.

Check flow direction (See page 1).

Filter bowl not being drained.

Drain more frequently.

High differential pressure.

Check filter idicator, replace element if necessary.

Defective seal

Check o-ring in element.

Unfiltered gas entering from source down stream of

filter.

Relocate filter or install additional filter.

High operating temperatures.

Install, clean, replace or relocate aftercooler, or relocate filter.

Short element

life

High compression temperatures causing varnish/car-

bon formation.

Use compression lubricant with good temperature stability. Lower lube rates where

possible. Use coarser grade filter element.

Oil/water emulsion overloading element.

Inspect moisture separator. Remove water with better separation.

WARNING

RD elements do not remove carbon dioxide (CO2),

carbon monoxide (CO) or other toxic gasses or fumes.

1. Shut off compressed air supply to the filter housing.

2. Completely depressurize filter housing.

3. After all pressure is removed form the filter housing, grasp

the filter bowl and turn it counter-clockwise to unscrew it from

the filter head. Strap wrenches can be used on the bowl if

necessary.

4. Remove used element by pulling downwards. Dispose of

used element properly.

5. Check housing o-ring for nicks or cuts. Replace as needed.

Make sure o-ring surface on bowl is clean.

6. Make sure o-rings are in place on new element. Grease

o-rings lightly with silicone free grease.

7. Clean and lubricate the threads on the filter bowl with a light

coat of silicone free grease. This allows the bowl to be easily

removed during next service.

8. Place filter bowl over element and turn it clockwise to screw

it into the head. Do not over tighten.

9. Close drain valve on filter (if installed).

10. Slowly repressurize the system and check for leaks. If leaks

are present, depressurize the system completely and check

the head to bowl o-ring and replace if necessary. Repres-

surize the system.

BYPASS

VALVE

DRAIN VALVE

(CUSTOMER

SUPLLIED)